High frequency mICrowave RF circuit board exposure and 24G/77G requirements

PCB manufacturers, PCB designers and PCBA manufacturers explain to you the exposure of high-frequency microwave RF PCB and the requirements for high-frequency microwave 24G/77G PCB

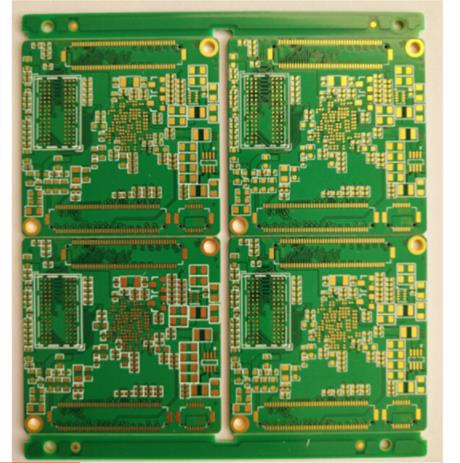

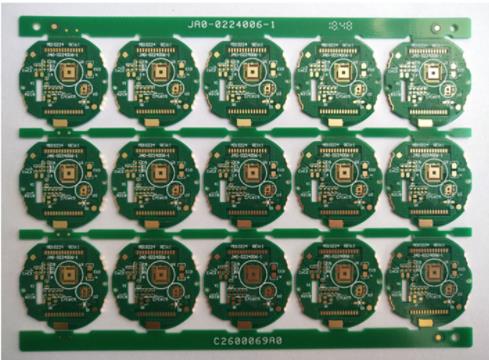

High frequency microwave RF PCB exposure includes circuit exposure and solder mask exposure. The function is to solidify the irradiated local area through ultraviolet light irradiation, and then develop to form a circuit diagram or solder mask pattern.

In the process of line exposure of high-frequency microwave RF circuit board, first paste a photosensitive film on the copper clad plate, and then put it together with the circuit graphic negative and expose it with ultraviolet light. The photosensitive film exposed by ultraviolet light will polymerize. The photosensitive film here can resist the scouring of Na2CO3 weak alkali solution during development, while the non photosensitive part will be washed away during development. In this way, the circuit pattern on the negative is successfully transferred to the copper clad laminate.

The solder mask exposure process of the high-frequency microwave RF circuit board is the same. Paint a photosensitive paint on the circuit board, and then mask the place to be welded during exposure, so that the bonding pad is exposed after development.

What are the requirements for high-frequency microwave board 24G/77G

In the field of high-frequency plate, Rogers is an undoubted giant. Typical products include 4000 series hydrocarbon resin and 3000 series PTFE. The latter is more used for 77G automotive radar due to its lower DF, but generally used for high-frequency mixed pressing due to poor processability, which makes it difficult to press multilayer line boards.

The main requirements of high-frequency microwave board are:

① Low DF: low dielectric loss;

② Thermal stability of DK and DF;

③ Appropriate DK: Low DK will improve the signal swarm speed and be beneficial to antenna design, but too low DK will also lead to too wide linewidth;

④ High frequency microwave plate water absorption: very SIMple, the DF and DK of medium with high water absorption will deteriorate after absorbing water vapor in the air. One of the advantages of LCP this year is that its water absorption is only 0.02%;

⑤ High frequency microwave board is uniform and stable: generally, the board is composed of glass fiber and resin, so the DK and DF of the whole board are uneven. Because the 77GHz transmission line is very thin, there will be impedance discontinuity. The corresponding solutions are to use the broken glass fiber and spread it as evenly as possible;

⑥ Roughness of copper foil for high-frequency microwave board: In the millimeter wave band, the proportion of conductor loss in the total loss will increase greatly. Copper foil with low roughness is not technically difficult. The difficulty is that the bonding force between the too smooth copper foil and the dielectric layer will become SMAller, leading to peeling. Rogers specially has LoPro series low roughness copper foil core, which is said to use some kind of potion;

⑦ Thermal expansion coefficient of high-frequency microwave plate: It is mainly considered that in some processing processes of pcb, if the thermal expansion coefficients of the medium and copper differ greatly, the conductor will break due to uneven stress, such as the famous 5880 series, DK ultra-low and DF ultra-low. However, the thermal expansion coefficient in the Z direction is large, leading to a greater risk of breakage of the conductor at the via, so it is rarely used for mass production (too expensive is also one aspect), It is generally used for students' water papers on antennas around the world. PCB manufacturers, PCB designers and PCBA processors will explain to you the exposure of high-frequency microwave RF PCB and the requirements for high-frequency microwave 24G/77G PCB.