How to arrange the position of clock PCB and PCB ink

PCB manufacturing, PCB design and PCBA processing manufacturers will explain how to arrange the clock PCB position and PCB ink

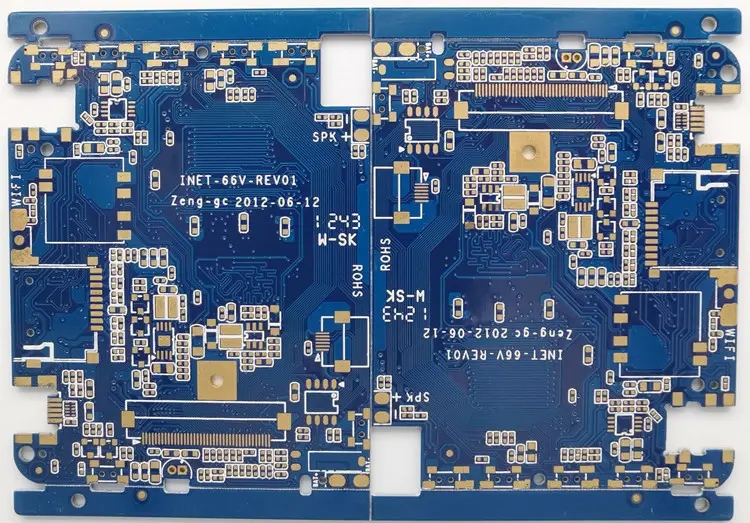

pcb circuit board is based on insulating board to replace the chassis of electronIC components. with the rapid development of our country, pcb circuit board has developed well in the industry.

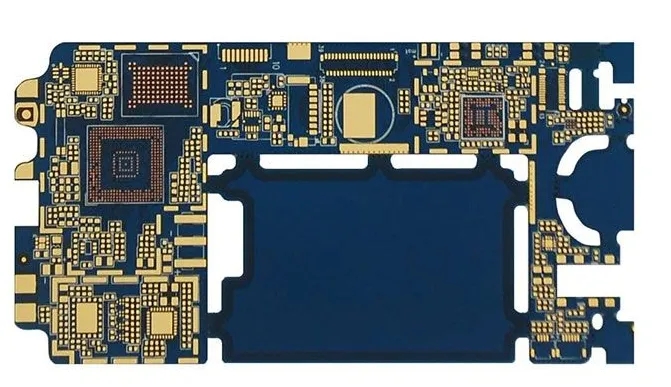

The basIC principles of PCB layout are as follows:

1 Reasonably arrange the position of the clock circuit.

2 Considering the distribution parameters of circuit components under high-frequency working conditions, all components should be evenly, neatly and compactly arranged on the double-sided circuit board, and the lead length between components should be minimized.

3 Analog circuits shall be separated from digital circuits. Eliminate the interference of digital signal to analog signal.

Before the pcb circuit board appeared, the interconnection between electronic components depended on the direct connection of wires to form a complete circuit. In the contemporary era, circuit board only exists as an effective experimental tool, and PCB circuit board has become the dominant position in the electronic industry.

On a basic PCB, parts are concentrated on one side and wires are concentrated on the other side. Because the wires only appear on one side, this kind of PCB is calLED single sided. Because there are many strict restrictions on the design circuit of a single panel (because there is only one side, and the wiring cannot cross and must go around a separate path), only early circuits use such boards.

Several Important Technical Properties of PCB Ink

In principle, it is impossible to separate from the combination of the above components whether the PCB printing ink quality is excellent. Excellent ink quality is the comprehensive embodiment of scientific formula, progressiveness and environmental protection. It is reflected in:

viscosity

Is the abbreviation of dynamic viscosity. It is generally expressed in viscosity, that is, the shear stress of fluid flow divided by the velocity gradient in the direction of the flow layer, in Pa. S or mPa. S. In PCB production, it refers to the fluidity of ink caused by external forces.

Conversion relation of viscosity unit:

1Pa。 S=10P=1000mPa。 S=1000CP=10dpa.s

Plasticity

Refers to the ink that remains its pre deformation properties after being deformed by external forces. The plasticity of ink is helpful to improve printing precision;

Thixotropic

Ink is colloidal when it is stationary, and viscosity changes when it is touched. It is also known as shake and sagging resistance;

mobility

(Leveling) The extent to which an ink spreads out under the action of an external force. The fluidity is the reciprocal of viscosity, which is related to the plasticity and thixotropy of ink. The greater the plasticity and thixotropy, the greater the fluidity; If the liquidity is high, the impression is easy to expand. Those with low mobility are prone to netting and inking, also known as reticulation;

Viscoelasticity

It refers to the capability of quick rebound of sheared and fractured ink after scraping. It is required that the ink deformation speed is fast, and the ink rebounds quickly to facilitate printing;

Dryness

It is required that the slower the ink dries on the screen, the better, and the faster the ink is transferred to the substrate, the better;

fineness

Particle size of pigment and solid material, PCB ink is generally less than 10 μ m. The fineness shall be less than one third of the mesh opening;

SPInnability

When the ink is lifted with an ink shovel, the extent to which the filiform ink does not break is called wiredrawing property. The ink filament is long, and there are many filaments on the ink surface and printing surface, making the substrate and printing plate dirty, or even unable to print;

Transparency and hiding power of ink

For PCB printing ink, according to the different uses and requirements, various requirements for the transparency and hiding power of printing ink are also put forward. Generally speaking, line ink, conductive ink and character ink all require high hiding power. The solder resist is more flexible.

ChEMIcal resistance of ink

PCB printing ink has strict standards for acid, alkali, salt and solvent according to different purposes of use;

Physical resistance of ink

PCB printing ink must meet the requirements of external scratch resistance, heat shock resistance, mechanical peeling resistance and various strict electrical performance requirements;

Safety and environmental protection of printing ink

PCB printing ink shall be low toxic, odorless, safe and environmentally friendly.

Above we have summarized the basic properties of twelve PCB inks, among which the viscosity is closely related to the operator in the actual operation of screen printing. The viscosity is of great importance to the smoothness of silk screen printing. Therefore, in PCB ink technical documents and QC reports, viscosity is clearly MARKed, indicating under what conditions and types of viscosity testing instruments. In the actual printing process, if the viscosity of the ink is too high, it will cause difficulties in missed printing, and the edge of the graphics has serious sawtooth. In order to improve the printing effect, thinner will be added to make the viscosity meet the requirements. However, it is not difficult to find that in many cases, no matter what viscosity you use, it is always impossible to achieve the desired resolution (resolution). Why? After in-depth study, it was found that ink viscosity is an important factor, but not. There is another quite important factor - thixotropy. It also affects the printing accuracy. PCB manufacturing, PCB design and PCBA processing manufacturers will explain how to arrange the clock PCB position and PCB ink.