PCB industry needs healthy and sustainable development

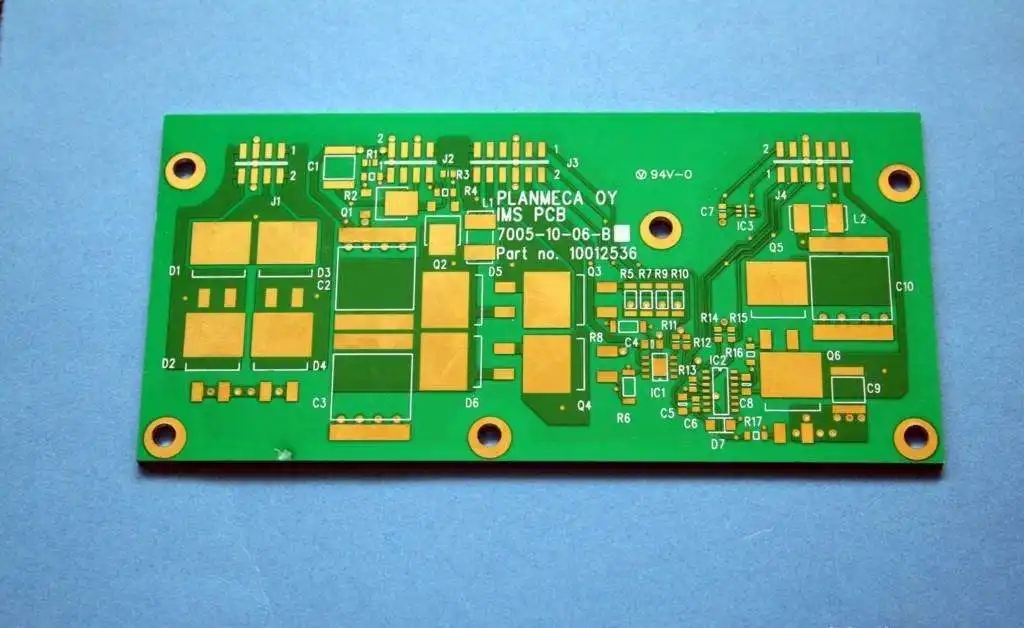

As a bridge carrying PCB components and connecting circuits, PCB is an indispensable key basIC component in the electronic information industry. Since 2006, China has surpassed Japan to become the world's largest producer of printed circuit boards, with both output and output value ranking first in the world. Its proportion in the total output value of the global board industry has risen from 31.18% in 2008 to 50.53% in 2017. According to the data of China Electronic Circuit Industry Association, the domestic PCB output value in 2017 reached US $29.7 billion. In this context, maintaining the sustainable development of the industry has become the consensus of the industry.

The Normative Conditions and Interim Measures issued this time are formulated in accordance with the principles of optimizing layout, adjusting structure, green environmental protection, promoting innovation, and classifying guidance. For PCB enterprises and projects, a quantitative standard system is formed from several dimensions such as capacity layout and project construction, production scale and process technology, intelligent manufacturing, green manufacturing, safe production, and social responsibility. Zhang Jin, secretary-general of China Electronic Circuit Industry Association, told China Electronics News: "As a participant in the formulation of the Specification Conditions, we are very happy to have it released. The release of the Specification Conditions has raised the threshold for PCB industry to enter, and has provided a strong guarantee for the steady and sustainable development of China's electronic circuit industry."

Xu Huan, Chairman of Bomin Electronics, said that the Normative Conditions and Interim Measures were issued on the basis of full research in the early stage and in combination with industry characteristics and future industry development trends. In his view, these two documents set the environmental protection threshold, technology threshold and scale threshold of the PCB manufacturing industry reasonably, and guide the development of PCB manufacturing industry cluster, which is a great good thing for the industry.

Liu Shaobai, chairman of Jingwang Electronics, believes that although the Normative Conditions have not implemented specific reward and punishment measures, they have formed clear and quantifiable guidelines for the existing per capita output value of PCB enterprises, the scale and input-output ratio of new projects, key technical indicators and technical capabilities, quality management, energy conservation and consumption reduction, environmental protection, safe production and other multi-dimensional business operations and internal systems. "In the future, there will be evidence to judge the closure of outdated capacity and the approval of new projects, which will help guide the industrial transformation and upgrading and structural adjustment, and accelerate the supply side reform of the industry. This is a guide to the healthy and sustainable development of the industry to prevent overcapacity." Liu Shaobai told China Electronics News.

An analysis report of Pacific Securities summarized the impact of the promulgation of the Standard Conditions on the industry. The report said that the Standard Conditions would help improve the overall operating efficiency of the industry and establish a positive image of the industry; It is conducive to the development of enterprises that curb blind investment and neglect management, improve the threshold of the industry, and improve the concentration; Although the technical indicators are not high, the trend of encouraging R&D remains unchanged.

Green manufacturing is an inevitable requirement for high-quality PCB development

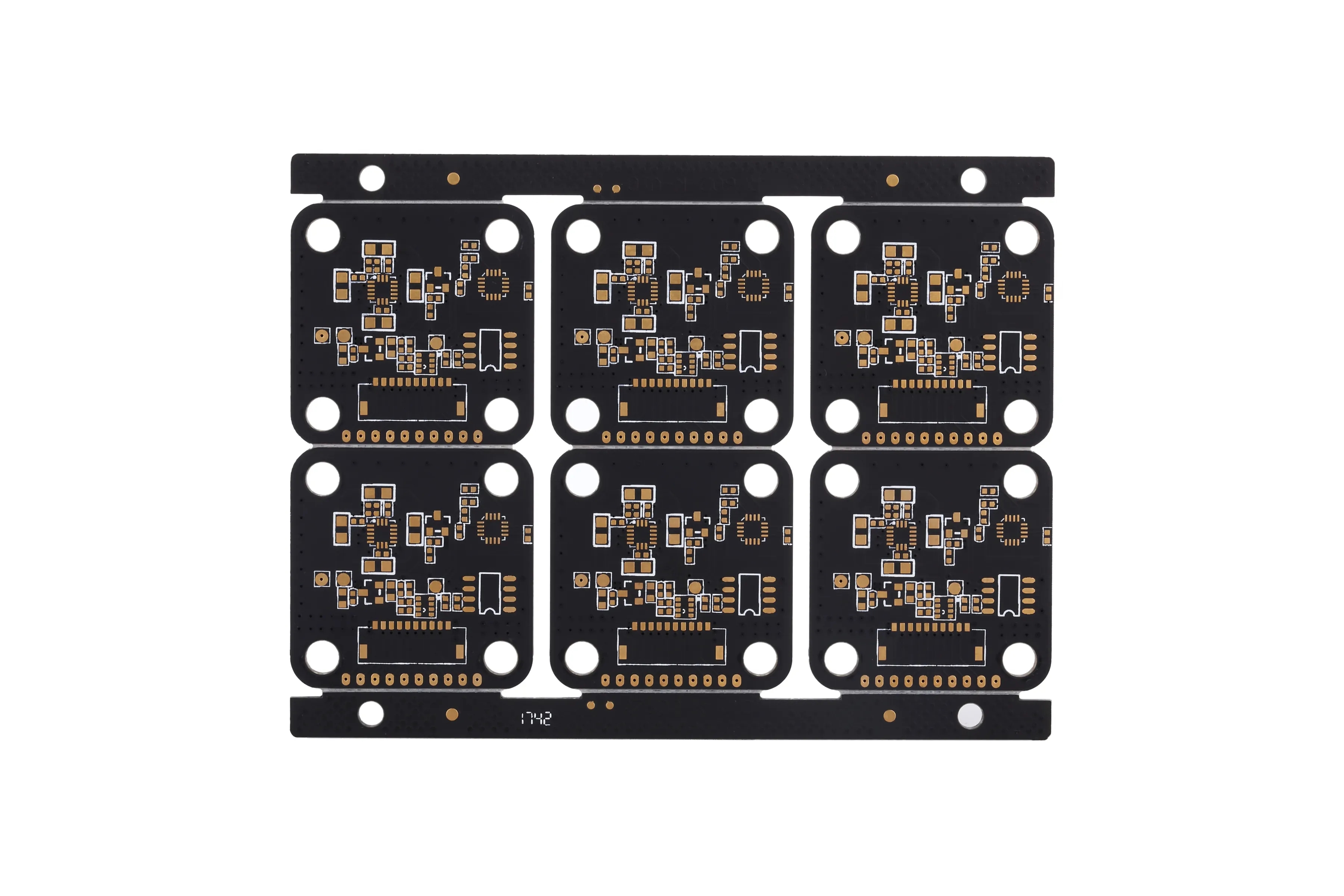

The Standard Conditions put forward clear requirements for intelligent manufacturing, green manufacturing and environmental protection. In terms of intelligent manufacturing, the Normative Conditions encourage enterprises to promote production equipment networking and data collection, actively build enterprise resource planning (ERP), manufacturing execution system (MES), supplier relationship management (SRM), warehouse management system (WMS) and other information systems, and promote the digital construction of enterprises; Encourage enterprises to actively carry out intelligent manufacturing, reduce operating costs, shorten product production cycle and improve production efficiency. In terms of green manufacturing, the Norms and Conditions require enterprises to continuously carry out cleaner production audit and pass the assesSMEnt and acceptance; Encourage enterprises to pass the certification and evaluation of the restriction on the use of hazardous substances in electrical and electronic products; Encourage enterprises to build green supply chains, establish resource saving and environment-friendly procurement, production, MARKeting, recycling and logistics systems, and promote stakeholders in the supply chain to comply with industry standards and norms; Enterprises are encouraged to build green factories and produce green products.

In fact, people in the industry have already reached a consensus on intelligent and green production in the PCB field. Liu Shaobai said in an interview with China Electronics News that the realization of PCB intelligent manufacturing can shorten the product development cycle, reduce resource and energy consumption, reduce operating costs, improve production efficiency, improve product quality, promote the high-end process of the PCB industry, and reshape new advantages in the manufacturing industry. Many domestic PCB enterprises have started intelligent manufacturing. For green manufacturing, Liu Shaobai believes that enterprises should consider the impact on the environment from the site selection of factory buildings. In addition, the following aspects should also be considered: in the design stage, safety, energy conservation, water conservation and less pollution should be considered from the factory design, process design, equipment selection, raw material selection and other aspects; In the construction stage, attention should be paid to environmental protection and safety; In the production stage, the enterprise also needs to build an advanced, complete, efficient and easy to implement production management system, formulate a complete and effective environmental emergency plan, implement a clean production system, improve the operation level, reduce waste, and achieve greater output by consuming the least natural resources.

"Only by unswervingly following the guidelines of the government, constantly strengthening R&D and innovation, improving the level of production technology, promoting automatic, information-based and intelligent production, and always adhering to the concept of environmental protection and green development, can PCB enterprises ensure sustainable development in the new situation." Shen Qingfang, chairman of Pengding Holding, said.

New application scenarios make PCB face greater challenges

In recent years, the rapid development of 5G, AI and Internet of Vehicles has brought new challenges to PCB industry. Taking 5G as an example, as a new generation of mobile communication technology, it is not only the enhancement of 4G, but also the indispensable foundation of mobile Internet, Internet of Things, Internet of Vehicles, industrial Internet, telemedicine, VR/AR and other fields. All countries in the world strive to seize the "commanding heights" of 5G industry and technology. printed circuit board is an indispensable "skeleton" component of 5G terminal products (such as base station, server, electronic equipment, etc.). Ultra high speed, ultra-low delay and super large connection require high integrity of signal transmission and high reliability of heat dissipation of 5G circuit. Therefore, signal transmission integrity and high reliability are challenges faced by PCB in the new situation. In this regard, Xu Huan believes that domestic enterprises should take the PCB market demand as the guide and carry out strategic layout in advance. Increase the investment in PCB technology research and development, focus on independent innovation, and co-exist multiple cooperative innovation channels. Conduct three major technical breakthrough rehearsals, including structural design, key methods, and industrialization, in order to overcome the key common technologies and large-scale production problems of printed circuits in emerging markets.