PCB copper coating and one eye distinguish double-sided board and multilayer board

PCB manufacturing, PCB design and PCBA processing manufacturers will explain PCB copper coating and distinguishing double-sided boards and multilayer boards at a glance

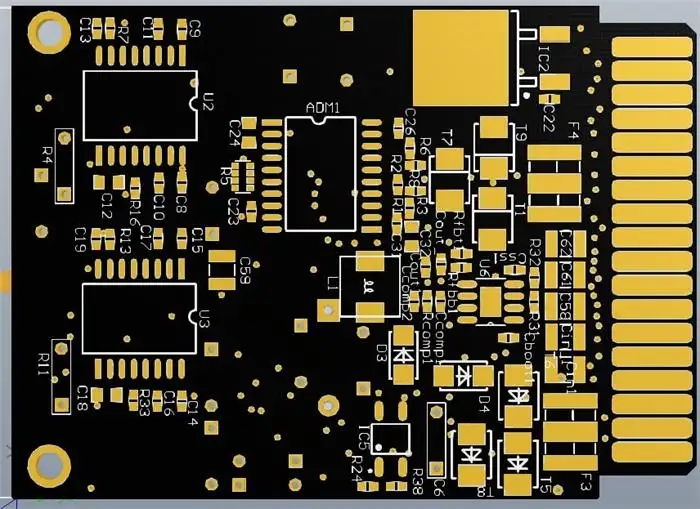

Copper coating is an important part of PCB design. The so-calLED copper coating is to use the idle space on the PCB as the reference plane and then fill it with solid copper. The signifICance of copper coating is to reduce the ground wire impedance and improve the anti-interference capability; Reduce voltage drop and improve power efficiency; Connecting with the ground wire can also reduce the loop area. Now, let professional engineers show you how to apply copper to PCB?

There are generally two basic methods for copper coating on PCB, namely, large area copper coating and grid copper coating.

Large area copper coating has dual functions of increasing current and shielding. However, for large area of copper coating, if wave soldering is carried out, the board may be warped or even blistered. Therefore, a large area of copper coating will generally open several grooves to alleviate the blistering of copper foil.

2. The SIMple grid copper coating mainly plays a shielding role, and the role of increasing current is reduced. From the perspective of heat dissipation, grid copper coating not only reduces the copper heating surface, but also plays a certain role in electromagnetic shielding. However, it should be pointed out that the grid is composed of lines in staggered directions. We all know that for circuits, The width of wiring has its corresponding "electrical length" for the working frequency of PCB "Yes, when the working frequency is not very high, or the role of the grid line is not obvious, once the electrical length and the working frequency match, the circuit will not work properly, and there will be a big problem of transmitting interference system working signals everywhere. So for engineers who like to use grid copper coating, it is recommended to choose according to the working conditions of the circuit board. Therefore, for high-frequency circuits with high anti-interference requirements, grid copper coating should be used more Copper; For low-frequency circuits with large current circuits, it is better to use complete large area copper coating.

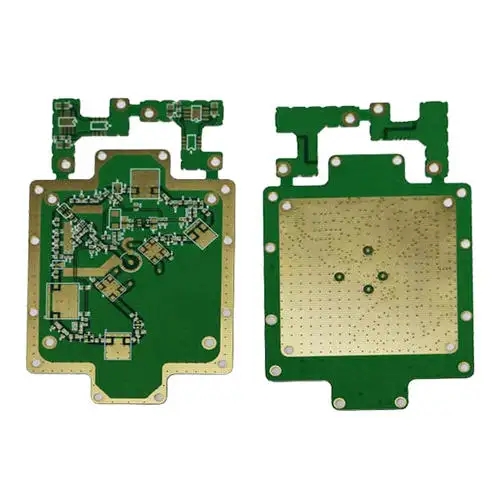

How to distinguish ordinary double-sided boards and multilayer circuit boards at a glance?

The appearance of a PCB multilayer circuit board is similar to that of a PCB double-sided circuit board. Ordinary people can't tell the difference between them without paying attention, or can't tell whether it is a double-sided circuit board or a multilayer circuit board. Then, how to distinguish ordinary double-sided boards and multilayer circuit boards with the naked eye? Now let professional PCB engineers teach you some methods to distinguish:

First of all, we should have a good understanding of the number of layers of PCB. The number of layers of the circuit board is in the inner layer. 1-2 layers are referred to as 1-layer PCB single panel, and 2 layers are referred to as PCB double-sided board. Generally speaking, the multi layer PCB refers to 3-48 layers; The higher the number of floors, the higher the unit price. Because the inner line is laminated, the technology content is high, and the machine cost is relatively high. The differences between ordinary double-sided boards and multilayer circuit boards are as follows:

1. The more layers, the greater the shadow in the sheet;

2. There are lines and ink on both ends of the PCB double-sided board;

3. There are no lines in the double-sided PCB, which is a pure sheet;

4. If the board is die punched, you can insert the board edge with your hand, and the board edge is smooth and recognizable;

5. The faint shadow can be seen in the multilayer pcb circuit board, which is a little dim in the light, and the circuit can be seen in the deep;

6. The board of multilayer PCB is usually made of KB material, which is smooth compared with the board surface, especially when it is cleaned after forming and processing;

7. If you want to know the exact number of layers, you can only know the exact data through the manufacturer's IM inspection or the development engineer's drawing board record.

PCB manufacturing, PCB design, and PCBA processing manufacturers will explain the difference between PCB copper coating and double-sided boards and Multilayer boards.