ElectronIC editor: explain the maintenance and inspection of PCBA in detail

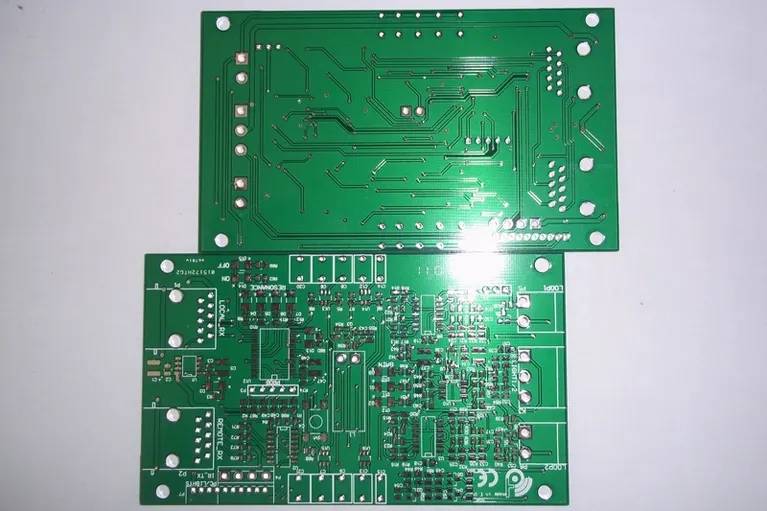

Printed Circuit Board (PCB), also known as printed circuit board (PCB), is an important electronic component, a support for electronIC components, and a provider of circuit connection for electronic components. Because it is made by electronic printing technology, it is calLED "printed" circuit board. Before the appearance of printed circuit board, the interconnection between electronic components depended on the direct connection of wires to form a complete circuit. Now, the circuit board only exists as an effective experimental tool, while the printed circuit board has become the absolute dominant position in the electronic industry.

In the process of SMT chip processing, production and use, problems occur in the whole PCBA manufacturing process and use process, including processing errors, improper use and aging of components, which may lead to abnormal operation or even poor use of the real product. Because many products just don't need to be replaced completely. This requires certain repair and maintenance of the circuit board inside. Then it involves the maintenance and detection of the circuit board.

Check the components: When the products need to be repaired in the SMT chip processing factory, it is necessary to first determine whether there are errors, leaks, and reverses in the components of each solder joint. It is also a situation to consider whether there are no materials. If the problems of errors, leaks, reverses, and authenticity are eliminated, check whether the circuit board with faults is intact, whether each component is obviously burned, and whether it is inserted incorrectly.

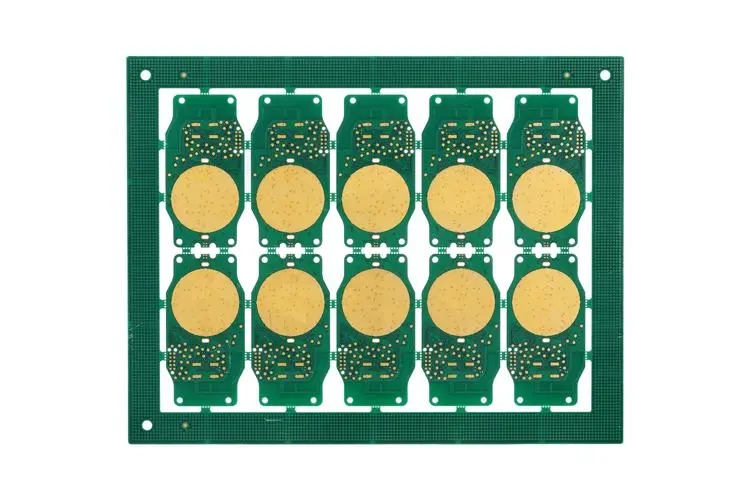

Analysis and detection of welding status: 80% of the defects of the circuit board are basically the defects of the solder joints. Whether the solder joints are full and whether there are any abnormalities, we can check whether there are defects invisible to the naked eye such as false solder, false solder, bubbles, short circuits, and whether the copper sheet is obviously cocked through the X-ray detection equipment.

Tool detection of components: If there is no way to judge whether there is any abnormality with the naked eye, XRAY detection equipment can be used. X-RAY detection equipment is mainly used for the detection of SMT, LED, BGA, CSP flip chip, semiconductor, packaging components, lithium battery industry, electronic components, automobile parts, aluminum die-casting castings, molding plastics, ceramic products and other special industries.

PCB manufacturers, PCB designers and PCBA manufacturers will explain the maintenance and inspection of PCBA.