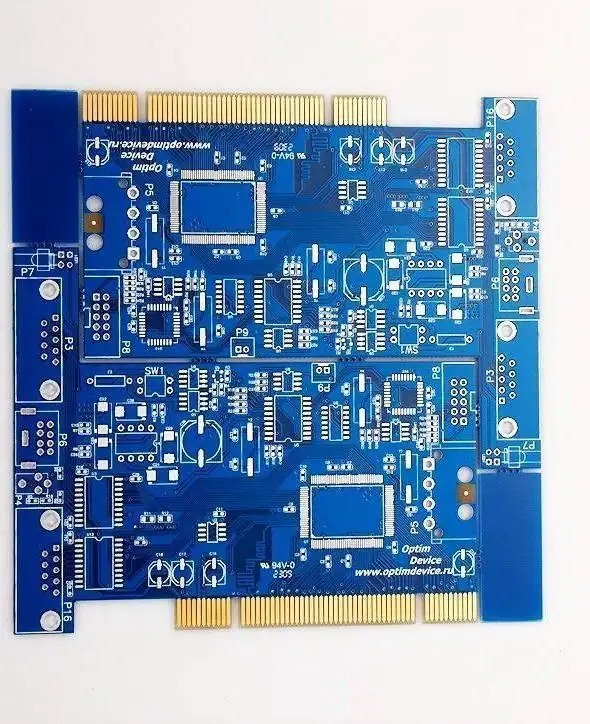

China is the global manufacturing center of electronIC products and the global consumer MARKet of electronic products, which provides sufficient market depth for the domestic PCB industry. At the same time, the domestic PCB industry chain is complete and the labor resources are sufficient, which makes the domestic PCB enterprises still have obvious competitive advantages.

What should aluminum substrate manufacturers pay attention to?

1、 Metal substrate Common structure Metal substrate, common structure is 1: conductive layer (also known as copper foil layer), used for circuit layout and component bonding pad position; 2: The insulation and heat dissipation layer (usually ceramic powder PP glue), as the name implies, gives play to the insulation and heat dissipation effect 3: metal base (usually aluminum based, copper based), as the carrier of copper foil and insulation layer, aluminum based takes the lead in the market share of metal substrate with high cost performance ratio and good machining performance.

2、 Tell you about the general performance of aluminum substrate. As a PCB commonly used for LED lighting, we are interested in knowing more about aluminum substrate. Aluminum substrate takes aluminum alloy as the carrier, and its thermal, electrical and mechanical properties are particularly important. Common parameters such as specific heat capacity, thermal conductivity, melting point range, linear expansion coefficient, conductivity, resistivity, hardness, fatigue strength, tensile strength, elastic modulus, elongation, cutting force, etc. The thermal conductivity is particularly important when it meets the national standard.

At present, the thermal conductivity of aluminum based copper clad laminates produced by different PCB manufacturers varies greatly. If the above measurement method is used, most of the thermal conductivity of aluminum based copper clad laminates in the domestic market are between, and their cost differences are likely to lead to unequal thermal conductivity. Therefore, when considering the thermal conductivity, it is not difficult to refer to the aluminum substrate price positioning and third-party testing.

Common PCB layout problems and puzzles

Whether a product is successful or not, on the one hand, it requires good functional quality, on the other hand, it requires beautiful appearance. You should lay out your circuit board like carving a handicraft. These questions and puzzles often occur in PCB component layout.

Whether PCB needs to be assembled, whether to reserve process edges, whether to reserve installation holes, and how to arrange positioning holes?

Does the PCB shape match the whole machine? Is the spacing between components reasonable, and is there any conflict in level or height?

How to consider impedance control, signal integrity, power signal stability and power module heat dissipation?

Is the distance between the thermal element and the heating element considered?

How can the EMC performance of the whole board be effectively enhanced by layout?

Is it convenient to replace components that need to be replaced frequently, and is it convenient to adjust adjustable PCB components? PCB

The main influence factors of FPC materials on the flexural properties are the type of materials and the thickness of materials. The molecular structure and orientation of copper foil, the bending resistance of calendered copper is obviously better than that of electrolytic copper foil; For the same variety, the thinner the copper foil is, the better its folding resistance will be; Generally speaking, the flexibility of epoxy resin adhesive is better than that of acrylic adhesive system, and epoxy system is the main flexible material; The thinner the thickness of the adhesive, the better the flexibility of the material, which can improve the flexibility of FPC; The thinner the insulation base material PI is, the better the flexibility of the material is, and the better the flexure of FPC is. The lower the tensile modulus of PI is, the better the flexure of FPC is.