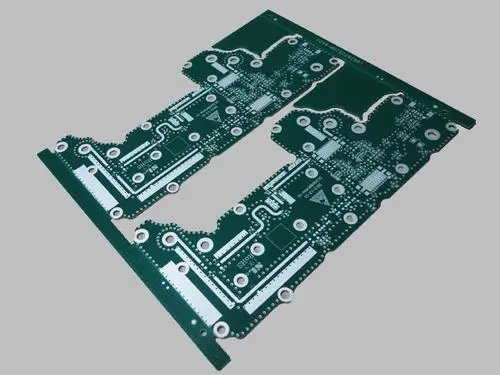

Thanks to the comprehensive advantages of PCB board and FPC board, soft and hard bonding boards have been widely used in electronIC products. In addition, since there are more material differences involved in soft and hard composite plates, all technical challenges mainly come from the selection of material combinations. For example, in the process of multiple laminations, the CTE difference of each layer of material in all directions should be carefully considered and used together with the stiffening plate, so that high-precision alignment lamination can be achieved to achieve deformation compensation.

At the same time, the structure design of the soft and hard composite board is also the hot spot of its development. Generally speaking, there may be many design schemes for soft and hard composite plates with equivalent functions. The actual design shall start from comprehensive consideration, including the reliability, space occupation, weight and assembly complexity of the product. In addition, the manufacturer's manufacturing capabilities and material elements should be considered for the best design with minimal procurement procedures. For example, common 3-layer to 8-layer soft and hard bonding plates can use CCL copper clad laminate with or without adhesion. SIMilarly, the covering layer of the flexible area in the soft and hard composite plate has different structures.

Another research and development trend of soft and hard combination board is the manufacturing of component embedded PCB. In most cases, it is required to embed resistors and capacitors in the rigid area without affecting the performance of the flexible area. This application puts forward strict requirements for materials for the second time. In addition, flexible PCB can work normally on CSP chip level packaging technology, while component embedded PCB structure poses challenges and requirements for packaging technology.

In China, with the rapid development of the technology and electronics industry and the national emphasis on health care, people's health awareness is also constantly strengthening. It has promoted the rapid development of Medical Equipment, which is widely used in ordinary families, and the MARKet demand is growing.

In the design and application of medical equipment, FPC Flexible circuit board, which is thin, flexible and flexible, is very suitable for the needs of portable medical equipment and is widely used in medical equipment. Many customers come to us to customize FPC boards for medical equipment, including ultrasonic wave equipment used in hoSPItals, probe equipment of various instruments, buttons of medical equipment and other household portable medical electronic equipment as consumer electronics, In China, the development trend is increasing year by year. Electronic manometer, portable blood glucose meter, electronic hearing aid, various monitoring instruments for the elderly, etc. are also widely used in ordinary families.

Medical equipment has very strict requirements for FPC flexible circuit board, and its precision is also very high. As Cassirer Electronics, the manufacturer of FPC flexible circuit board, we now have mature production technology on FPC boards of electronic pressure gauges, electronic hearing aids, portable blood glucose meters, elderly monitors, and other products. At the same time, we are also working hard with many customers in the medical equipment industry to develop products in different fields. Welcome more customers with medical FPC to our company to discuss cooperation and jointly promote the development of the medical equipment industry.