How to print solder paste on circuit board

Printing solder paste on the circuit board and then connecting the electronIC parts to the PCBA board through the reflow furnace is the most common method used by circuit board manufacturers today. The printing of solder paste is actually a little like painting on the wall. The difference is that in order to apply the solder paste to a certain position more accurately and control the amount of solder paste, a more accurate special steel plate must be used to control the printing of solder paste.

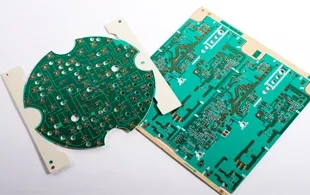

▲ Before solder paste printing. There is only gold plating on the circuit board.

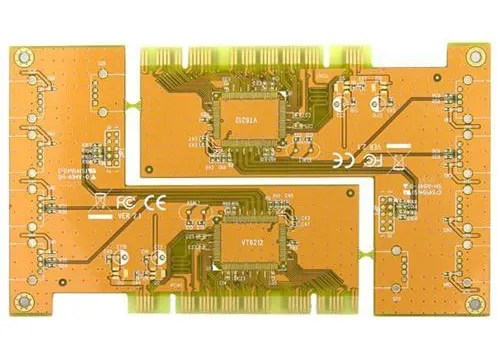

▲ After the solder paste is printed, the solder paste here is designed as a "field" type to avoid the solder paste being too concentrated in the center after melting.

Solder paste printing is the basis for the quality of PCB soldering, and the position and amount of solder paste are the key. It is often seen that solder paste printing is not good, resulting in solder short and solder empty problems. However, if you really want to print the solder paste well, you must also consider the following factors:

Squeegee type: The appropriate scraper should be selected according to the characteristICs of different solder pastes or red glue. Currently, the scraper used for solder paste printing is made of stainless steel.

Scraper angle: the angle of the scraper to scrape the solder paste is generally 45~60 °.

Scraper pressure: The pressure of the scraper will affect the volume of solder paste. In principle, when other conditions remain unchanged, the greater the pressure of the scraper, the less solder paste will be used. Because of the high pressure, the gap between the steel plate and the circuit board is compressed.

Scraper speed: The speed of the scraper will also directly affect the shape and quantity of solder paste printing, and also directly affect the quality of solder printing. Generally, the speed of the scraper will be set at 20~80mm/s. In principle, the speed of the scraper must match the viscosity of the solder paste. The faster the mobility of the solder paste is, the faster the scraper speed should be, otherwise it will be easy to seep. In general, the faster the scraper is, the less solder paste it contains.

Demoulding speed of steel plate: If the demoulding speed is too fast, it is easy to cause the phenomenon of solder paste wire drawing or tip drawing, which may affect the effect of placement.

Is a vacuum block used? The vacuum seat can help the circuit board smoothly stick to the fixed position, and strengthen the tightness between the steel plate and the circuit board. Sometimes only a SMAll amount of products produced at one time can use universal thimbles/ejectors to replace vacuum blocks.

Is the circuit board warped? The deformed circuit board will cause uneven solder paste printing, which will cause short circuit in most cases.

Steel plate tapping. The opening of steel plate directly affects the quality of solder paste printing, which needs to be explained in a special chapter.