How can PCB manufacturers ensure the high-performance design of PCB

With the rapid development of electronICs and communication technology, today's PCB design is facing a completely new challenge. It is mainly shown in the following aspects:

1. The signal edge rate is getting faster and faster, and the clock speed on and off the chip is getting higher and higher. The clock frequency is no longer a few megabytes in the past, and hundreds of megabytes or gigabytes of clocks are more and more common on boards. Due to the rapid development of chip technology, the edge rate of the signal is also getting faster and faster. At present, the rising edge of the signal is about 1ns. This will lead to more prominent system and board level SI and EMC problems;

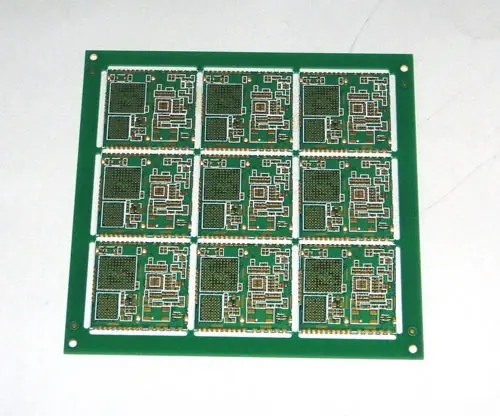

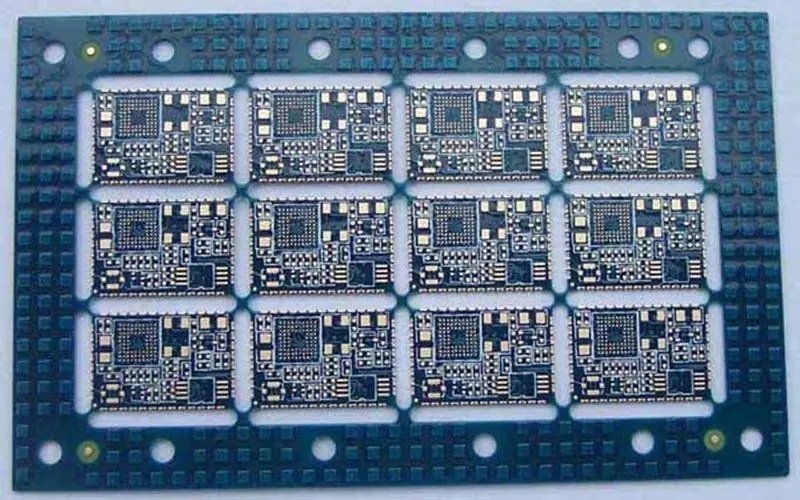

2. The integration scale of circuits is getting larger and larger, and the number of I/Os is getting more and more, which makes the interconnection density of single boards continuously increase; As the functions become more and more powerful, the integration of circuits becomes higher and higher. The level of chip processing technology is also getting higher and higher. The past DIP packaging has almost disappeared on the current boards, and SMAll spacing BGA and QFP have become the mainstream packaging of chips. This increases the density of PCB design.

3. The time for product R&D and MARKeting is decreasing, which makes us face the severe challenge of one-time design success; Time is cost, time is money. In the field of electronic products, which are updated very quickly, if the product is launched one day earlier, its profit opportunities will be much greater.

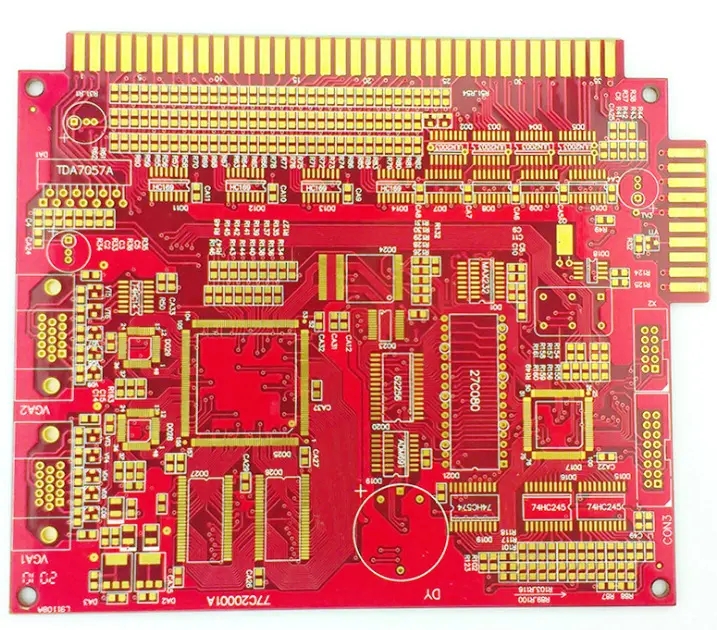

4. PCB is the physical carrier of product realization. In high-speed circuits, the quality of PCB is related to the function and performance of products. The same device and connection, different PCB carriers, their results are different.

Therefore, the design process has been slowly changed. In the past, the design of logic function often accounted for more than 80% of the hardware development and design, but now this proportion has been declining. At present, the design of logic function only accounts for 50% of the hardware design, and the design of PCB also accounts for 50% of the time. Experts predict that in the future design, the logic function cost of hardware will be smaller and smaller, and the cost of high-speed PCB design such as developing design rules will reach 80% or more.

All these are just instructions. PCB design will be the focus and difficulty of current and future design.

In general, our PCB design mainly focuses on the following points:

1. Function realization

2. Stability of performance

3. Easy processing

4. The beauty of veneer

The function realization is the first step of our PCB. In the past design, due to the low rate of signal edge and clock frequency, as long as the logical connection is correct, the physical connection will not affect the performance. But this view is not used in the current design. An example can well illustrate this point:

The circuit board designers of a famous image detection system manufacturer in the United States recently encountered a strange thing: a product that has been successfully designed, manufactured and marketed seven years ago has been able to work very stably and reliably for a long time. Recently, the product offline from the production line has had problems, and the product cannot operate normally.

Therefore, the correct connection of logic cannot enable the correct implementation of functions. The quality of physical connection is also the main condition for function realization.

The guarantee of performance depends on the design of PCB, which we all understand. The performance test results of the same logic connection, the same device and different PCBs are different. Good design not only has high stability, but also can pass various demanding tests. But it is impossible to achieve this effect if the design is not ideal. In some low-end products, many manufacturers use the same chipsets and SIMilar logical connections. The only difference is the level of PCB design. The difference of products is mainly reflected in PCB design.

The ease of processing is also an important indicator of PCB design. Good PCB design is convenient for processing, maintenance, testing and manufacturing. The quality of PCB is not only related to the production efficiency of PCB manufacturers and SMT manufacturers, but also to the convenience of our testing and debugging.

Elegant appearance is also an element of PCB design. The overall beauty and atmOSPhere make people feel comfortable. PCB is also a handicraft. A good PCB will make people linger.

PCB design is a comprehensive discipline, which is the product of the coordination of quality, cost, time and other aspects. There is no best in PCB design, only better. In a word, the design of high-Speed PCB is a serious challenge in today's system design field. Whether it is the design method, design tools, the composition of the design team, or the design ideas of engineers, it needs to be actively and seriously addressed. PCB processing, PCB assembly, PCB design, PCBA manufacturers will introduce how to ensure the high-performance design of PCB.