Blackening of the combination board and characteristICs of high-speed circuit board

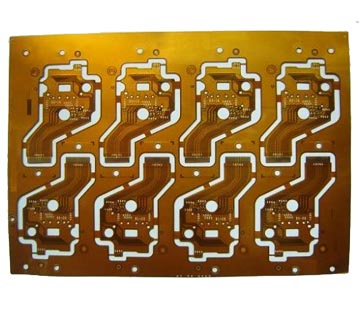

PCB manufacturers, PCB designers and PCBA manufacturers explain the characteristics of the black processing of the inner layer of multi-layer automobile soft and hard combination boards and the design of high-speed circuit boards.

There is a very difficult problem in the production of multilayer automobile soft and hard composite plates - blackening of the inner layer of multilayer plates. What is the most effective method of black oxidation? What's the role of inner blackening? Today we will introduce the relevant content to you!

Inner layer black oxidation: passivating copper surface; Improve the surface roughness of the inner copper foil, thereby improving the adhesion between the epoxy resin board and the inner copper foil.

Black oxidation method for general inner layer treatment of automobile soft and hard composite laminate:

Black Oxidation Treatment of Automobile Soft and Hard Bonded Laminates

Brown oxidation method for automobile soft and hard composite Multilayer board

Low Temperature Blackening Method for Multilayer Panels of Automobile Soft and Hard Bonded Panels

High temperature blackening method is adopted for automobile soft and hard composite multilayer plate, which may cause thermal stress in the inner layer, which may lead to interlayer separation after lamination or cracks in the inner copper foil.

1、 Brown oxidation:

The black oxidation treatment products of automobile soft and hard bonding plate manufacturers' multilayer plates are mainly copper oxide, rather than the so-calLED cuprous oxide, which is some wrong statements in the industry. The binding energy of copper atom and oxygen atom on the oxide surface and the ratio of copper atom to oxygen atom can be determined by ESCA (electronic specific chEMIcal analysis) analysis; Clear data and observation analysis show that the blackening product is copper oxide, which does not contain other components.

General composition of blackening solution:

Oxidant sodium chlorite

PH buffer trisodium phOSPhate

sodium hydroxide

surface active agent

Or ammonia solution of basic copper carbonate (25% ammonia)

2、 Relevant data

1. Peel strength: 1oz copper foil shall be at the speed of 2mm/min, 1/8 inch wide, and the tensile force shall be more than 5 pounds/inch;

2. Oxide weight; It can be measured by gravimetric method and generally controlled at 0.2 -- 0.5mg/c ㎡;

3. The significant factors that affect the tear strength through the analysis of related variables (ANDVA: the analysis of variable) mainly include:

① Concentration of sodium hydroxide

② Concentration of sodium chlorite

③ Interaction between trisodium phosphate and immersion time

④ Interaction between the concentration of sodium chlorite and trisodium phosphate

The tear strength depends on the filling ability of the resin to the crystal structure of the oxide, so it is also related to the relevant parameters of lamination and the relevant properties of resin pp.

The length of acicular crystal of oxide is 0.05 mil (1-1.5 um), which is the best, and the tear strength is also relatively large.

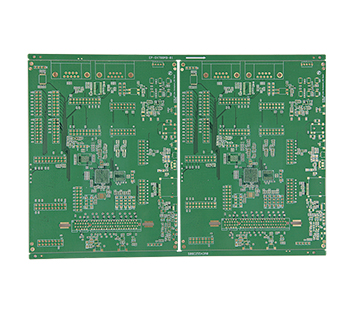

What are the characteristics of multilayer boards used in high-speed circuit board design?

When designing high level circuit boards, multilayer circuit boards are usually used instead of single-layer and double-layer circuit boards. Why is this? Today brings you the reason why high-speed circuit boards use multilayer boards! Let's have a look!

Multilayer board has many features that are not available in single layer board and double layer board, and it is precisely because of these features that high-speed circuit board design uses multilayer board instead of other circuit boards.

The following is a summary of the characteristics of multilayer boards!

1. The power supply is very stable;

2. The circuit impedance is greatly reduced;

3. The wiring length is greatly shortened.

In addition, from the perspective of cost, although the cost of multilayer circuit boards is higher than that of single-layer circuit boards, the cost difference between multilayer circuit boards and single-layer circuit boards is not as high as expected when considering other factors such as the miniaturization of circuit boards and the convenience of noise reduction. According to the data we know, when we SIMply calculate the area cost of the circuit board, the area of the double-layer circuit board that can be purchased every day is about 462mm2, and the area of the Four layer circuit board is 26mm2. That is, if the use area of the four layer circuit board can be reduced to 1/2 of the double-layer circuit board, the cost is the same as that of the double-layer circuit board. Although multiple layers in batches will affect the cost per unit area of circuit boards, there will be no price difference of 4 times. If there is a price difference of more than 4 times, as long as the use area of the circuit board is reduced to less than 1/4 of the double-layer board as much as possible.

circuit board manufacturers, circuit board designers and PCBA manufacturers will explain the characteristics of combination board blackout and high-speed circuit boards.