PCB products are a complICated thing. We must plan them well to get twice the result with half the effort. If there is no process, we will be very tired. Generally, the following processes will be shared with you.

Basic process of circuit board design

First of all, define the design requirements of the circuit board. ElectronIC design comes from requirements. Only when the requirements are clear can the future process be determined. Be sure to communicate the detaiLED requirements with the product manager or the customer and sign for confirmation to prevent the requirements from being modified during the design process. A SMAll requirement change may cause the whole design scheme to be overturned.

Develop technical solutions and chip selection. After the requirements are clear, the technical scheme is designed. When designing the technical scheme, more schemes should be made as backup, and the advantages and disadvantages of each scheme should be compared from the aspects of circuit board cost, production process, design cycle, etc. for discussion.

Technical proposal review. After the technical proposal is put forward, the product manager, department leaders and relevant colleagues shall be organized to review it. Technicians generally dislike the review and think that the review cannot play its proper role. In fact, the purpose of technical proposal review is to determine the technical proposal after unanimous confirmation. If the technical proposal cannot be implemented or is overturned in the future, it will not put all the pressure and responsibility on one person.

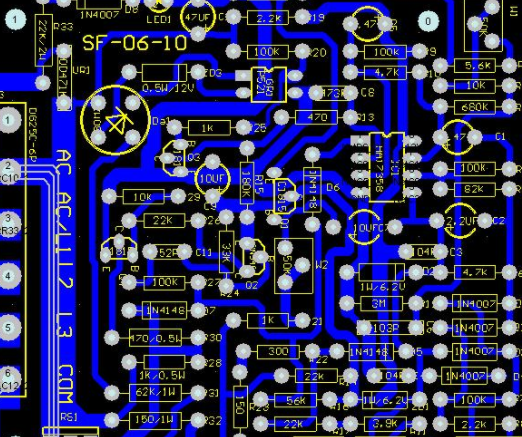

Design circuit and PCBlayout. After the technical scheme is determined, it will be implemented. This stage includes the design of circuit board schematic diagram, the drawing of component library, the design of component packaging, PCBLayout, etc. If necessary, organize colleagues to review and discuss technical details together. The purpose of this discussion is to find problems in the circuit design process.

Commissioning and product testing. After the PCB template comes back, seize the time to weld, debug the hardware circuit, debug the program, and draw a flow chart when programming. After the function comes out, the template should be tested according to the test plan.

Prepare certification data and process documents. After the product test is completed, it is necessary to prepare the work related to product certification and certification, and prepare the process documents to facilitate other colleagues to prepare for small batch mass production.

The above is the general process of electronic product design. It should be noted that records and signatures must be made at the links to be discussed in order to prevent the occurrence of boiler swing.

How to Design PCB Board

To design a PCB, the following steps are required:

Plan the board layer and the definition of each layer. In addition to two layers, four, six or more layers may be required. At the beginning of the design, it is necessary to determine the number of layers to be designed and plan the definition of each layer;

Consider the Layout of components. Good component layout plays a vital role in the performance and stability of products. When placing components, they shall be placed according to functions, signal flow direction, high and low voltage, etc;

Requirements for wiring. Especially for RF circuits and high-speed boards, PCB wiring and PCB routing are very critical;

Handling of grounding. The ground wire treatment is also very critical, and many interferences are introduced through the ground wire. When grounding each point, it is necessary to consider whether to select multi-point grounding or single point grounding.

PCB design is a very systematic work. Different circuits have different considerations, and specific situations need specific analysis.