Quality Control in PCBA and SMT production

1 PCBA patch processing quality control

The production and processing process of PCBA involves a series of processes such as PCB manufacturing, procurement and inspection of electronIC components provided by PCBA, SMT chip processing, parts processing, program startup, testing and aging. The supply chain and manufacturing chain are long. Any problem in any link will lead to a large number of unqualified batches of PCBA boards, and cause adverse consequences. In view of this situation, the quality control of PCBA chip processing is a very important quality assurance in electronIC processing. What is the main quality control of PCBA processing?

After receiving the PCBA processing order, it is particularly important to hold a pre production meeting It is mainly for process analysis of PCBGerber files and submitting a manufacturability report (DFM) according to different customer needs. Many SMAll manufacturers do not attach importance to this, but tend to be here It is not only easy to cause quality problems due to poor quality PCB design, but also a lot of rework and repair work

2. Procurement and inspection of electronic components provided by PCBA

To strictly control the procurement channel of electronic components, we must obtain goods from large traders and original manufacturers, and avoid the use of second-hand materials and counterfeit materials.

Circuit board

In addition, it is necessary to set up a professional PCBA incoming material inspection post to strictly inspect the following items to ensure that there is no failure of components

PCB: Check the temperature test of the reflow furnace, whether the fly wire vias are blocked or leaking, and whether the board surface is bent.

IC: Check whether screen printing is identical to BOM, and store it in a constant temperature and humidity environment.

Other common data: check screen printing, appearance, power measurement, etc.

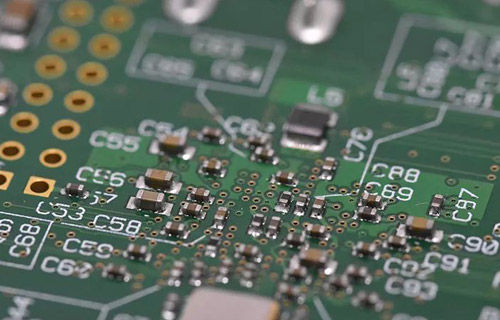

3. SMT assembly

Solder paste printing and reflow furnace temperature control system is the key to assembly, which requires higher quality and better processing of laser die. According to the needs of printed circuit boards, some need to add or reduce wire mesh, or U-shaped holes, and only need to make wire mesh according to process requirements. Among them, the temperature control of the reflux furnace is very important for the solder paste wetting and the steel mesh firmness, which can be adjusted according to the normal SOP operation guidelines.

In addition, strict implementation of AOI testing can greatly reduce defects caused by human factors.

4. Piece processing

The design of wave soldering die is the key in the process of welding parts. How to use the mold to maximize the yield is a process that PE engineers must continue to practice and summarize.

5. PCBA processing board test

For orders with PCBA test requirements, the main test contents include ICT (circuit test), FCT (function test), combustion test (aging test), temperature and humidity test, drop test, etc.

The second is the quality control method in the chip production process

In the SMT chip production, processing and manufacturing process, the loss of solder paste, patch adhesive and electronic components should be taken as one of the important process control contents for quota management. SMT production can directly affect the quality of products. It is necessary to control processing parameters, processes, personnel, equipment, raw materials, production, processing and testing, workshop environment and other factors.

There should be a clear post responsibility system for important posts. The operators of patch processing shall be strictly trained and assessed, and shall work with certificates. SMT chip processing plant shall have complete and formal manufacturing management methods, such as first article inspection, self inspection, mutual inspection and inspector inspection system. Those unqualified in the previous process shall not be transferred to the next process.

Quality Control in SMT chip Production

1. Product batch management. The Nonconforming Product Control Procedure shall clearly specify the isolation, identification, recording, review and disposal of nonconforming products. Generally, the maintenance times of shape memory alloy shall not exceed 3 times, and the maintenance times of electronic components shall not exceed 2 times.

2. Maintenance of smt chip production equipment. The key equipment shall be regularly inspected by full-time maintenance personnel to keep the equipment in good condition, track and monitor the equipment status, timely find problems, take corrective and preventive measures, and timely maintain and repair.

3. Production environment

1. Water and electricity supply.

2. The environment of SMT chip production and processing line requires temperature, humidity, noise and cleanliness.

3. SMT chip production and processing site (including electronic component library) anti static system

4. The entry-exit system, equipment operation procedures and processing discipline of SMT chip production and processing line.

4. The production site is set reasonably and the identification is correct; Raw materials and products in the warehouse shall be stored by category, stacked neatly, and the standing book shall be consistent.

5. Civilized production. Including: clean and free of sundries; Work in a civilized manner without barbaric and disorderly behaviors. On site management must have systems, inspections, assesSMEnts, and records. "6S" (organization, rectification, cleaning, cleaning, quality, and service) activities must be carried out every day.