Processing of PCB pad and use of FPC data

FPC flexible printed circuit is a circuit made on a flexible cutting surface, whICh can be covered or uncovered (usually used to protect FPC circuits) Because FPC can be bent, folded or moved repeatedly with various pipes, its application is more and more extensive

The base film of FPC is usually made of polyimide (PI) (abbreviation) and polyester.

(Polyester, PET for short), the data thickness is 12.5/25/50/7.5/125 um, and 12.5 and 25 um are commonly used. If FPC needs to be welded at high temperature, the data is usually PI, and the base plate of PCB is usually FR4.

The covering layer of flexible circuit board is made of dielectric film and adhesive film or flexible dielectric coating to prevent pollution, moisture, scratches, etc. The main information is the same as that of the base material, namely polyimide. Amine (polyimide) and polyester (polyester), the thickness of common data is 12.5 um.

The FPC design needs to bond the layers together, so FPC glue (adhesive) is required. flexible boards are commonly used in acrylic acid, modified epoxy resin, phenolic butyraldehyde, reinforced plastics, pressure sensitive adhesives, etc., while single-layer flexible circuit boards are not bonded with adhesives.

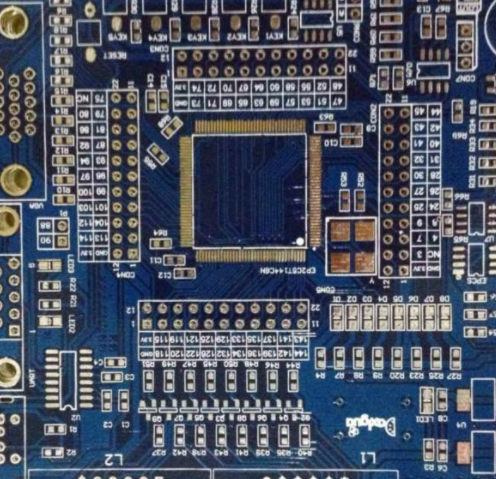

Circuit board

In many applications, such as welding equipment, flexible plates need to be externally supported. The main information includes PI or polyester film, glass fiber, polymer information, steel plate, aluminum plate, etc. PI or polyester film is a common material for flexible plate reinforcement, and its thickness is generally 125 um. The hardness of glass fiber (FR4) reinforcement plate is higher than that of PI or polyester, and it is used in hard places.

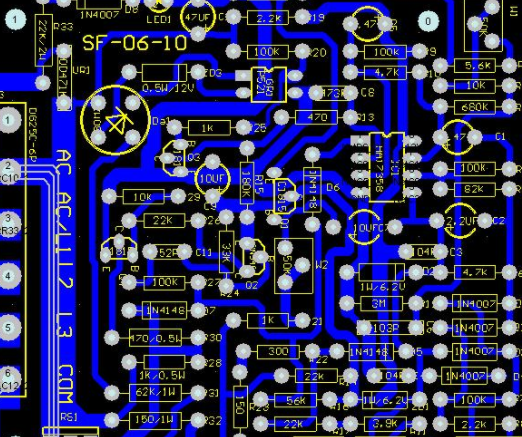

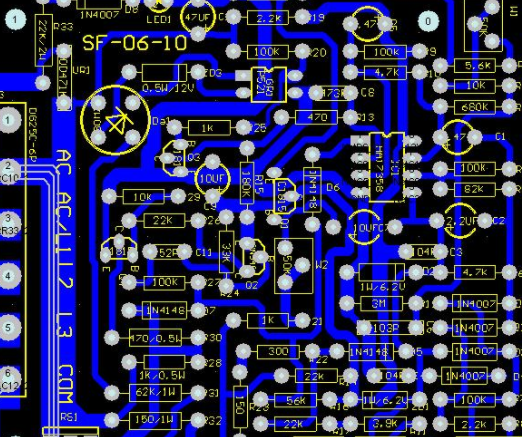

There are many ways to handle FPC pads relative to PCB pads The following are common situations:

ChEMIcal nickel gold is also calLED chemical immersion gold or immersion gold. Generally, the thickness of the electroless nickel layer used on the copper metal surface of PCB is 2.5um - 5.0um, and the thickness of the gold (99.9% pure gold) layer immersed is 0.05um - 0.1um (previous PCB). Factory workers use alternative methods. Replace the gold coins in the PCB pool. Technological advantages: smooth surface, long storage time, easy to weld; Suitable for fine pitch components and thinner PCBs. It is more suitable for FPCs because it is thinner. Disadvantages: Not environmentally friendly.

2. Advantages of tin lead electroplating: flat lead tin can be directly added to the pad, with good solderability and uniformity. This method must be used on FPC for some processes (such as hot strips). Disadvantages: lead is easy to be oxidized, and the storage time is short; Need to pull the electroplating line; It is not environmentally friendly.

3. Selective Gold Plating (SEG) Selective gold plating means that some areas of the PCB are gold plated, while other areas are subject to another surface treatment. Gold plating refers to coating a nickel layer on the copper surface of a printed circuit board, and then electroplating a gold layer. The thickness of nickel layer is 2.5mm to 5.0mm, and the thickness of gold layer is usually 0.05mm to 0.1mm. Advantages: The gold plating layer is thick, with strong oxidation resistance and wear resistance. "Golden Finger" usually uses this treatment. Disadvantages: environmental protection, cyanide pollution.

4. Organic solderable protective layer (OSP) This process refers to the surface coating with specific organic substances on the copper surface of bare PCB. Advantages: Provide a very flat PCB surface to meet environmental requirements. Applicable to PCB with fine pitch components.

Disadvantages: PCBA needs to use traditional wave soldering and selective wave soldering, and OSP surface treatment is not allowed.

5. Hot air leveling (HASL) This process refers to 63/37 lead tin alloy covering the exposed metal surface of printed circuit board. The thickness of hot air leveling white wax coating is 1um - 25um. The hot air leveling process is difficult to control the coating thickness and pad pattern. It is not recommended to use PCB with fine pitch components, because the fine pitch components require high flatness of the pad; The hot air leveling process is applicable to thin Flexible circuit boards.

In design, FPC usually needs to be used with PCB. In the connection between the two, board to board connectors, connectors and gold fingers, hot rods, soft and hard adhesive plates and manual welding are usually used for different applications. In terms of environment, designers can use corresponding connection methods.

In practical application, determine whether ESD mask is required according to application requirements. When the flexibility of FPC is not high, it can be realized through solid copper and thick medium. When flexibility is needed.

Due to the flexibility of the FPC, it is easy to break under pressure. In addition, the protection of the FPC requires some special means.

Common methods are:

1. The minimum radius of the inside corner of the flexible profile is 1.6 mm. The larger the radius, the higher the reliability and the stronger the tear resistance. At the corner of the shape, a line can be added near the edge of the circuit board to prevent the FPC from being torn.

2. The crack or groove on the FPC must end with a round hole with a diameter of no less than 1.5 mm, which is also necessary when two adjacent parts of the FPC need to be moved separately.

3. In order to obtain better flexibility, it is necessary to select the bending area in the uniform width area, and minimize the FPC width change and uneven track density in the bending area.

4. Stiffeners, also known as stiffeners, are mainly used to obtain external support. Materials used include PI, polyester, glass fiber, polymer, aluminum, steel, etc. Reasonable design of the location, area and data of the stiffening plate has a great impact on avoiding FPC tearing.

5. In multi-layer FPC design, air gap delamination design is required in the area that is often bent during product use. Try to use thin PI data to increase the flexibility of FPCs and prevent FPCs from cracking during repeated bending.

6. If space permits, a double-sided tape fixing area shall be designed at the connection between the gold finger and the connector to prevent the gold finger and the connector from falling off during bending.

7. The FPC positioning screen shall be designed at the connection between the FPC and the connector to prevent the FPC from tilting during assembly