PCB protection of five high-power devICes at present

At this stage, the following protection methods are suitable for PCB electronic products, automatic electronic control equipment and power semiconductor devices:

1. Fuse method

This is a common protection method The fuse is usually connected in series at the power input end of the circuit to control the total current of all circuits Its working principle is that after the circuit has a problem, the fault current flowing through the fuse is increased, and the power supply is cut off to achieve the purpose of protection, so that it can be heated and self melted The fuse method has the advantages of SIMple implementation, easier maintenance, lower cost, and complete power failure in the protection process. In addition, it is widely used in all PCB electronic circuits and PCB electronic equipment at this stage

However, since the total current flowing through the fuse is the total current of the circuit, the change of the operating current of a single power semiconductor device cannot cause its effective response; In addition, due to the slow melting speed of the fuse, only when the power sEMIconductor device is damaged or a serious short circuit fault occurs in the circuit. When the fault current is doubLED, it will fuse. In this case, it can only prevent the further expansion of the fault, but cannot protect the power semiconductor devices.

2. Main circuit current detection method

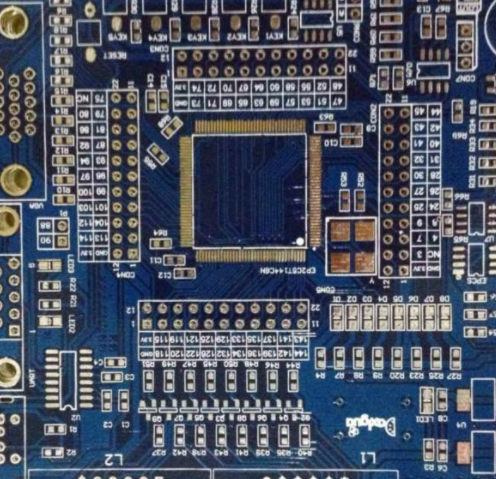

pcb board

The method is to connect the detection elements (detection resistors, transformers, etc.) in series at the input end of the power supply of the main circuit, obtain the corresponding current or voltage signal by detecting the voltage drop or current amplitude of the total current in the circuit on the detection elements, and then amplify the circuit to compare the action threshold of the protection circuit to determine whether it is protected;

In view of the use of electronic technology, compared with the fuse method, the protection method improves the sensitivity and response speed, but the method still detects the total current of the circuit, and the working current of the fault power semiconductor device is only a few minutes of the total current. One or even one tenth of the change cannot cause effective response of the protection circuit.

This method always responds after PCB fault current is formed, resulting in delayed detection results and protection actions, which cannot meet the protection requirements of power semiconductor devices. This protection method is the same as the fuse, which can only prevent the fault from further expanding after the power semiconductor device is damaged and malignant over-current fault occurs. There is still no way to protect electrical equipment.

3. Detection method of working current of power devices

This is a commonly used protection method for power semiconductor devices, which has a certain protective effect on power semiconductor devices. This method is to connect a detection element (resistance or current transformer, etc.) in the working current path of the protected power semiconductor device, detect the working current of the protected device on the detection element, and then process the circuit to obtain the current or voltage signal. The fault signal is protected by a fuse or the power is turned off.

The working principle and circuit structure of the current detection method for power devices are the same as those for the main circuit The difference is that the detection object is the working current of the protected equipment. In addition, the sensitivity is higher than that of the main circuit current detection method, and the effect is also better If this method uses electronic equipment to cut off the current path to achieve protection, it can play a protective role after the tube has an overcurrent fault

However, because the scheme still uses current detection method, that is, to detect and protect the fault signal after the fault is formed, and the protected device is affected by high voltage and large current, this still leads to the delay of signal acquisition. If the power margin of the protected device is SMAll or the circuit fault is serious, the protected device will still be damaged immediately; If the power margin of the protected equipment is large and the degree of failure is not serious, the equipment will not normally be damaged

4. Detection method of voltage parallel connection of power devices

As the name implies, this method is to connect the protection circuit in parallel with the protected power device, and obtain signals by detecting the voltage of the protected device when it is working. Judge whether there is a fault in the circuit according to the voltage. The protection method adopts the local protection method, that is, the protection is realized by forcibly cutting off the control signal of the protected power device itself and forcing it to stop working. (Detect the voltage of the protected equipment and directly protect the protected equipment)

Because this method detects voltage signals, when the circuit is abnormal, faults can be found immediately, and when PCB fault current has not been formed, protection can be implemented to avoid the impact of fault current on the equipment.

The protection method also has the following characteristics:

1. The protection circuit is connected in parallel. There are no series connected components in the main working circuit, so the power utilization rate is high and there is no heat source

2. The detection object is the working voltage of the protected power device. The input impedance of this protection circuit is high, the power consumption is small, and the detection accuracy is high.

3. What is detected is the working state of the protected object itself. The protection is directly applied to the protected object, which is highly targeted and timely and reliable

The disadvantage of this protection circuit is that it only qualitatively detects the working state of the protected pcb device. In this case, if it is used for voltage control power equipment, it can only play an ideal role in protecting load short circuit and serious overcurrent fault.

5. Parallel connection method for measuring working voltage drop

Due to the on resistance of the power semiconductor device itself, overload and overcurrent in any case will lead to its saturation voltage drop or new operating voltage drop, that is, regardless of the operating state of the semiconductor device, the device itself will have a corresponding operating voltage drop value; Monitor the voltage drop when the power semiconductor device is turned on, and judge the situation and degree of overcurrent and overload according to the voltage drop.

The above is some related knowledge PCB power equipment The continuous development of power devices requires the continuous efforts of our scientific researchers to promote the continuous development of science and technology and make our pcb electronic products more

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.