Manufacturing Technology and ApplICation of Industrial PCB

Industrial PCB manufacturing technology:

Industrial PCB design:

When it comes to industrial PCB manufacturing, PCB design and layout is the most critical stage.

The design steps of manufacturing industrial PCB are important because the design will determine the appearance or efficiency of PCB.

You should hire a designer who can design your PCB to meet all the requirements of your industrial application.

To avoid various errors in your design, try the latest automation software, which can help you quickly detect errors and resolve them.

Industrial PCB Prototype:

After successfully completing the first step (design and layout), try to find a manufacturer specializing in industrial PCB prototyping.

Because prototyping is a key step in industrial PCB manufacturing.

Once the prototype is ready for use, send it to the third-party company for testing as much as possible and find faults and errors.

After receiving the test results, send them to your designer so that he can make changes based on the results.

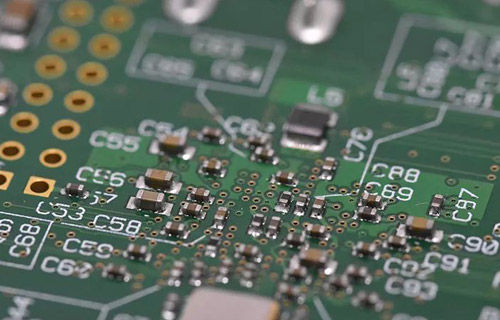

circuit board

Now send the edited design to the manufacturer for final production. When finished, proceed to the next step.

Industrial PCB components:

After manufacturing the final PCB, we must assemble the components on it.

You can assemble PCB from any manufacturer.

However, before selecting a manufacturer, it is important to check its assembly history and capabilities. Check the company's review.

See if they have enough experts to convene the meeting. This will give you a better understanding of its quality.

Finally, find out the installation cost of each plate. The quality cost ratio of manufacturers should be higher. Learn more about delivery time and other costs.

As far as industrial printed circuit boards are concerned, efficiency and quality are the main factors. In addition, even if you need to bear additional costs, you should keep them as much as possible.

High quality industrial PCB Features:

Strong substrate:

The base material of high quality PCB must be durable and reliable, especially because it is used in high power industrial applications.

High quality industrial PCB must have the ability to withstand large current.

High quality substrates help prevent warping at high temperatures and resist strong impacts from moving parts.

It is also easy to maintain and replace parts when necessary.

Thick solder mask:

A high quality PCB must have a thick solder mask. Helps protect it from corrosion.

It is not only a thick welding mask, but also can save the entire wiring board in welding and component placement.

Test:

PCB manufacturing process needs testing. PCB prototypes must be tested before the final product is launched.

After testing, try to find the error and try to fix it in the final product. After that, you can release the final product containing high quality PCB.

Defective PCB will destroy your brand because it cannot provide high-quality products. So focus on testing.

Copper Cladding:

I can tell you frankly that copper plating is essential for manufacturing high-quality and reliable industrial PCB. Before choosing a manufacturer, always make sure they can provide you with the final CCL. If they are not ready, do not select them for your PCB manufacturing. This may meet the IPC4101B/L quality standard.

Quality components:

High quality industrial PCB must contain high quality components.

Before assembling components, you need to ensure that they are high quality components and that they originally belong to the actual manufacturer.

Industrial PCB application:

Manufacturing equipment:

Industrial PCB is widely used in the construction of industrial equipment to deal with high configuration systems in the industrial field.

Measuring equipment:

In industrial environments, there are many types of equipment that require different power supplies.

This kind of power equipment relies heavily on industrial PCB.

Industrial robots:

In this era of machine learning and artificial robots, many robots are used in the industrial field to reduce manufacturing time and cost.

These robots work with many active industrial PCBs. The central processing system of these robots is composed of industrial PCB, including high configuration processor, expensive microcontroller, various resistors, capacitors, LED and many other important components.

Industrial automation system:

Industrial automation systems are very useful for automating the entire manufacturing process and controlling manufacturing cells from remote devices.

This type of automation system consists of complex industrial PCB. Due to its high configuration and operation capability, industrial PCB is used to operate such complex systems.

Industrial PCB has more uses Industrial PCBs are widely used in various industrial applications