Professional and beautiful PCB pattern design skills

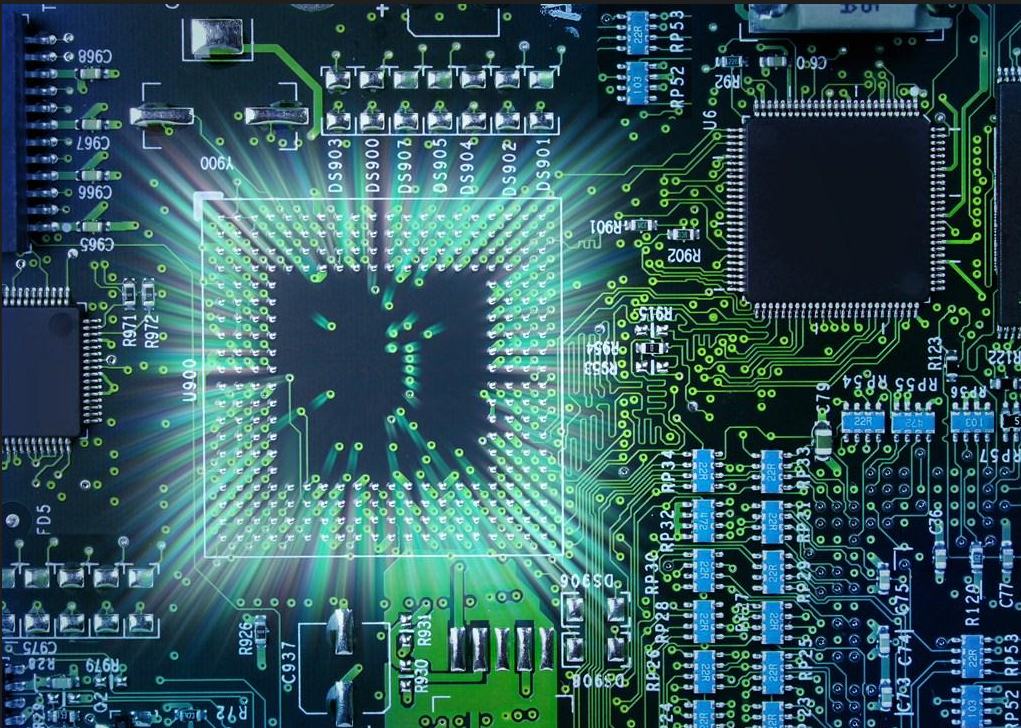

Pattern is a repeated sequence of repeated design, mainly for decoration All printed circuit boards have patterns. The creation of patterns precedes the design of the circuit board itself This<a href="/tw/" target="_blank">circuit board pattern is like the road map of a track, containing a set of symbols representing various parts of the circuit These components include resistors, switches, nodes, diodes, etc

If there is no suitable model, PCB design will be a labor-intensive task. The first is the pattern, and then the design of the circuit board. This mode instructs the position of each element (diode, resistor, switch, node, etc.). So, what are the advantages of PCB pattern?

How to generate such a pattern? This paper discusses the basIC factors related to PCB patterns, such as pattern types, advantages, and how to select patterned fabrics.

The Importance of PCB Graphics in PCB

The circuit board pattern in PCB has many advantages. For example, a circuit board pattern designed with correct piping can significantly reduce electrical noise. If you happen to encounter a PCB consisting of a properly placed model, you will find that it EMIts less electronic sound. However, if the mode is incorrect, music may reduce the overall performance of the circuit.

Circuit board

In addition to the circuit board pattern that reduces electrical noise on the circuit board, the contour has another significant advantage. Proper layout of the circuit board pattern will also improve or improve the power efficiency of the circuit board. The efficiency of a circuit depends to a large extent on the way the circuit pattern is displayed on a printed circuit board. If the layout of the circuit board you designed or purchased is inappropriate, please rest assured that the power efficiency of the circuit board will not keep up.

Last but not least, circuit board patterns are crucial because they help to easily identify defects on a circuit board. A good circuit board pattern flows from one end to the other to detect any errors and repair them. On the other hand, when unstructured circuit board patterns are involved, detecting such defects is very challenging. Because of defect detection and repair, circuit board patterns without meaning or process may consume a lot of manpower.

Different types of circuit board patterns

As mentioned earlier, patterns are repetitive sequences of repeated design, mainly decorative. When it comes to printed circuit boards, based on the above advantages, circuit patterns are crucial. Before studying different types of PCB patterns, good design needs to follow the following requirements:

Voting should be easy.

Its cost must be very low.

It must be easy to repair.

It should be able to withstand considerable impact without damage.

It should have a long shelf life without changing its size.

It should be easily removed from the mold.

It cannot turn, especially in the presence of dust and mold.

With the continuous development of technology, the different circuit modes found in the printed circuit boards we use are also evolving. In short, there are hundreds of circuit patterns on various printed circuit boards. In other words, with the number of designers in the MARKet, the types of models are huge. Different circuit board manufacturers choose their models. Some of the most common board patterns include:

Single pattern

Gating mode

Skeleton pattern

Two piece

Shell pattern

Scan Mode

Copy Mode

If you are interested in circuit board patterns, you will realize that not all circuit boards contain the same model. Some look symmetrical, some look helical, and some look linear.

How to generate circuit board patterns

This circuit board pattern will not create itself with some mysterious pipeline Most PCB manufacturers use some equipment or software to design PCB patterns These devices and software platforms used to generate circuit board patterns are calLED circuit board pattern generators Depending on the needs or user preferences, circuit board designs vary greatly from one PCB component to another

Printed circuit board is one of the most complex electronIC components. Recall that they need a unique model to ensure that they work as expected. In order to provide the best design for your PCB, it is best to use the appropriate PCB pattern generator. There are many circuit pattern generators. These include EAGLE software, Altium Designer, Express PCB software, etc. PCB design software.

1.PCB123

2.KiCAD EDA

3.OrCAD

4. EAGLE software is still one of the most popular circuit board pattern generators.

When choosing a board pattern generator, you must do your best in this area. There are hundreds of them on the market, but some of the best ones include those mentioned above. Others include PCB artist, PCB drawing, Altium Designer 17, DIP Trace, and PCBWeb. All of these are the best PCB pattern generators used by most PCB designers and DIY enthusiasts. In addition to being readily available (some of which include free trial versions), many of them are portable and feature rich.

Factors to be considered when selecting patterned fabrics for circuit boards

The type of fabric used to create circuit board patterns depends on the individual or manufacturing company. However, in most cases, one of the most common colors of these fabrics is green. Do you often encounter circuit boards with pink, red or white circuit patterns? You may not have seen this before.

But why is it green? People think green fabric is ideal because it is a little gentle to the eyes. In addition, green is a conductive color that needs to be processed, allowing manufacturers to use it for a long time.

Therefore, what factors should be paid attention to when selecting printed circuit board pattern printed circuit board fabric? First, you need to select a material that requires a SMAll amount of chemicals and shows better design details than other materials In addition, when selecting PCB data, please select environmental protection data in the manufacturing process, so that you can also protect the environment

Not all of the above. You also need to select a material that can be easily adjusted to different PCB sizes. There are many fabric materials that can pose challenges, especially when trying to change them to fit the correct pipe. Finally, the content type you choose to use must be durable and healthy.