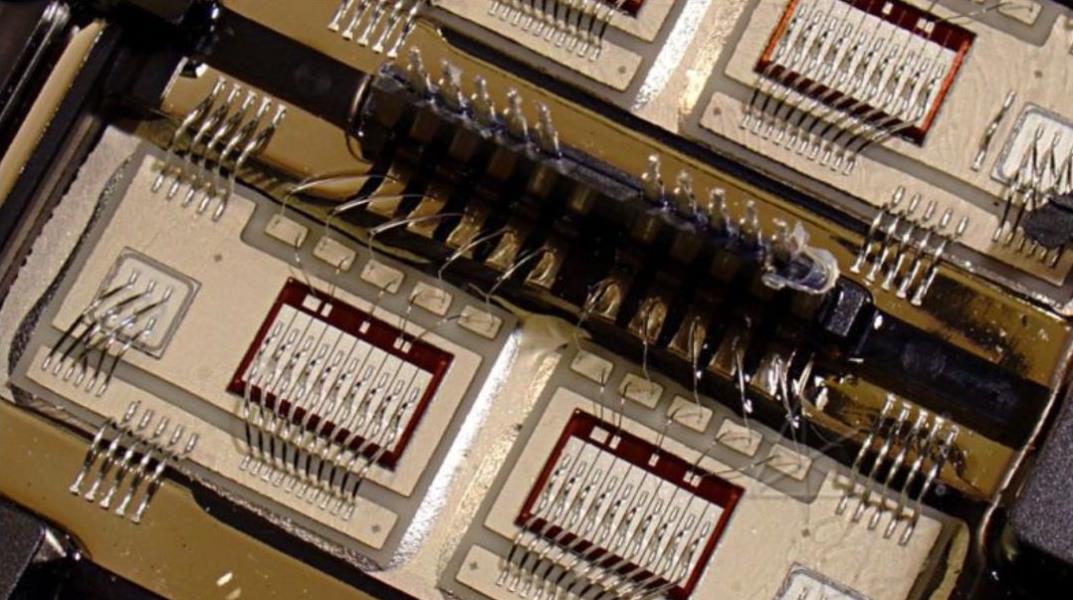

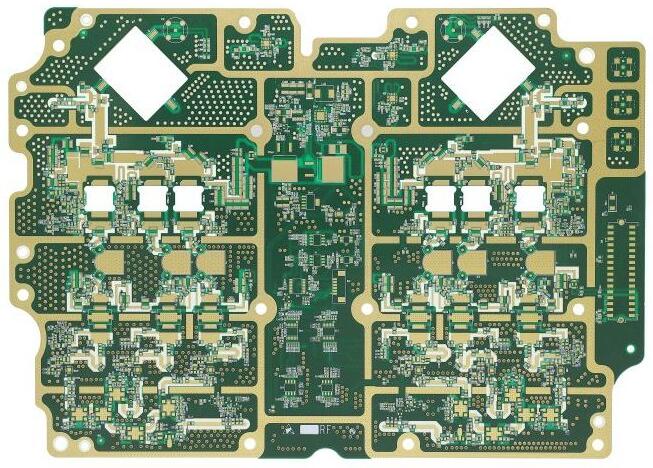

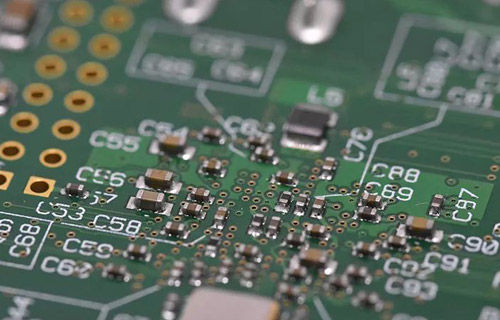

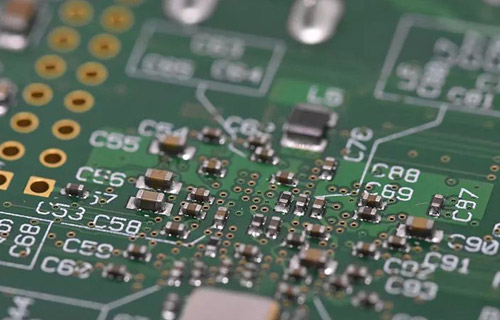

Comparison between rigid PCB and flexible PCB

This printed circuit board connects the power components in one position through careful wiring to form a fully functional unit printed circuit boards can be as SIMple as a single layer of copper, but they are more likely to consist of multiple layers The two main types of PCB are Flexible circuit board and rigid circuit board As the name implies, rigid PCBs are inflexible, although flexible PCB can be easily bent or formed with other pipes to fit the specified system Although rigid and flexible PCB are still popular, mainly because of their low cost, they have recently gained MARKet share from rigid PCBs due to their versatility and other advantages flexible boards are recommended and preferred for the following reasons:

Flexibility

Unlike rigid printed circuit boards, Flexible PCBs are still a popular choICe because they are easy to bend, fold and even crease to fit or match the final application The ability to rotate easily allows designers to have one aspect of the circuit that provides the device, rather than having the terminal device built around Electronic devices and circuit boards Unlike rigid printed circuit boards, which may not be suitable for wearable electronic devices, flexible printed circuit boards are very suitable for wearable electronic devices and medical devices, folding mobile phones, sensors, and implants

Connectivity

Unlike rigid printed circuit boards, flexible printed circuit boards provide a good connection between other circuit boards, user interfaces in electronic packages, and electronIC components.

This is why many designers prefer rigid printed circuit boards. In addition, flexible printed circuit boards provide good connectivity in applications that require continuous bending of circuits during the working life of the equipment. In this regard, flexible printed circuit boards have been widely used for connection of foldable electronic products, notebook computers and displays.

Circuit board

Flexible PCB is light in weight

In terms of weight, rigid PCB is slightly heavier than flexible PCB. Low voltage circuit boards bring lighter end products, which are crucial in the current electronic market. Electronic device designers and consumers prefer SMAll, lightweight devices. Rigid printed circuit boards are not suitable for many applications because they are a little heavier than flexible printed circuit boards. Due to its light weight, the flexible circuit is suitable for UAVs, various Medical Equipment and unmanned vehicles.

Flexible PCB has good durability

Although rigid PCB is generally thicker and stronger than flexible PCB, flexible PCB can withstand shock and vibration more effectively. In other words, in terms of durability, flexible PCB has a certain degree of durability compared with rigid PCB. Flexible PCBs help achieve long-term reliability, functionality, and product life. Flexible PCBs are widely used in weapons, missile guidance systems, medical electronics, satellites and applications requiring good environmental viability.

Flexible PCB is durable

Another reason why designers prefer flexible PCB to rigid PCB is that flexible PCB has high resistance. Unlike flexible PCB, rigid PCB is most likely to be bent or damaged due to chEMIcal substances, heat and radiation. Flexible printed circuit board (FPC) has high resistance to extreme weather and other harmful environmental conditions. The ability to withstand extreme weather conditions, radiation or chemicals explains the large number of applications or uses of flexible printed circuit boards in many applications, such as Automotive electronics.

Miniaturized version of existing technology

In recent years, electronic applications requiring small packages, low power consumption and enhanced functions have proliferated. In terms of printed circuit boards, miniaturization, small size and low weight are also obvious. By using flexible PCB technology, engineers can create PCB with strict size limits. Using flexible printed circuit boards, manufacturers can now manufacture smaller electronic and optical products and equipment. Good examples of such products and accessories include computers, mobile phones and most medical devices. Different from rigid PCB, flexible PCB meets the requirements of miniaturization.

Shock and vibration resistance

Compared with rigid PCB, flexible PCB can withstand severe impact and vibration. Flexible printed circuit board is an ideal choice for high vibration and high impact environments. Flexible printed circuit boards are more likely to survive in high stress environments than rigid PCBs that may not operate as expected and cause equipment failure, especially when they are exposed to severe and rapid vibration.

Those who work in industries that use high vibration instruments will find flexible printed circuit boards to be an ideal choice because they help to counteract any wear caused by sustained high shock and vibration. If you are looking for a circuit board that can not only withstand severe vibration, but also provide some of the best functions, then you'd better choose a flexible printed circuit board.

High temperature and high-density applications

In addition to being able to withstand shock and vibration, flexible printed circuit boards are also widely used in high-temperature and high-density applications. In many cases, polyimide or similar polymer materials are used to produce flexible printed circuit boards. Compared with rigid PCB materials, polyimide is one of the materials with better heat dissipation effect.

Flexible printed circuit boards can withstand extreme temperature conditions, which is why they are widely used, especially in drilling measurement in the oil and gas industry. Because it can withstand high temperature conditions, flexible printed circuit boards provide many benefits for manufacturers. Flexible printed circuit boards are the preferred choice for most engineers dealing with PCB applications.

Will flexible circuits replace rigid circuit boards in all applications?

There is no doubt that flexible printed circuit boards are very convenient. However, they will not completely replace rigid printed circuit boards for all other applications. Cost efficiency is the main obstacle to the implementation of dedicated flexible circuit board design in consumer products. The manufacturing and installation cost of rigid printed circuit board is not high. However, in an ideal situation, innovative products are those that combine flexible circuits when necessary, and use stable and reliable rigid circuit boards to reduce assembly and manufacturing costs.

Some manufacturers use rigid flexible hybrid PCBs to reduce costs. Rigid and flexible PCBs are widely used in medical equipment and notebook computers, in which rigid boards are connected by ribbon flexible circuits. WellPCB produces rigid and flexible printed circuit boards at competitive prices.

The cost of flexible PCB

According to cost, flexible PCB are slightly more expensive to manufacture and install than stubborn PCB s Unlike rigid printed circuit boards, flexible printed circuit boards need to create some additional project files Some flexible PCB designs have Coverplays, pressure-sensitive adhesives, and stiffeners This may require engineers to manually review flexible designs and create custom programs, which is why flexible printed circuit boards are expensive compared to stubborn PCBs

Although the manufacturing and installation cost of rigid PCB is slightly lower, it is difficult to ignore the advantages of flexible PCB. Although flexible printed circuit boards are expensive, many engineers choose them because they are durable and can perform product functions as needed. However, it is worth noting that costs usually increase with the number of layers. Many other factors can affect the value of PCBs. If you are interested, you can read more of our articles to understand.

generalization

The application of FPC is very common, and its applications in many industries, such as medical, military and automobile, are also developing The flexible PCB you will notice has many advantages Do you want to buy hard printed circuit boards or flexible printed circuit boards in the market?