What are the preparation methods of mICrowave dielectric ceramics and microwave dielectric ceramics?

1 What is microwave dielectric ceramics

Microwave dielectric ceramics PCB refer to a new type of ceramic functional materials used in microwave frequency circuits (mainly in the 3.00MHz~300GHZ frequency band)

In the microwave frequency band, various polarization mechanisms are stable, and the dielectric constant of the data basically does not change with frequency Therefore, according to the size of the dielectric constant, it can be divided into three categories: low dielectric constant, medium high dielectric constant

Low dielectric microwave dielectric ceramic systems, such as Al2.O3-TiO2 series and magnesium titanate series, are used in fields with strict requirements for dielectric loss, such as satellite communications, military radar, etc., due to their high quality factor

Intermediate microwave dielectric ceramic systems such as (Zr, Sn) TIO4 have high Q value

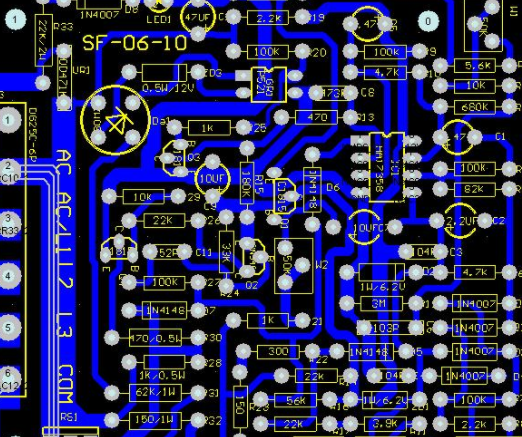

PCB board

High dielectric microwave dielectric ceramics can promote the miniaturization and integration of microwave communication equipment and harmonic oscillators, and are widely used in high-capacity integrated circuits and low-frequency communication equipment

Microwave dielectric ceramic powder is not a single data, but a data system in which multiple data are mixed in proportion In the preparation process, rare earth oxides are also added Many studies have shown that doping appropriate rare earth elements can improve the sintering efficiency of microwave dielectric, the density and dielectric efficiency of ceramics

2. Preparation method of microwave dielectric ceramics

The production methods of microwave dielectric ceramic materials include solid phase reaction method, sol-gel method, hydrothermal method, precipitation method, etc

1) The solid phase reaction method The solid phase reaction method is a traditional process method, which has the advantages of mature process, SIMple operation and high cost performance It is suitable for mass production and is the most commonly used method in industrial production However, its disadvantage is high sintering temperature, easy to form second phase and local abnormal grain growth, which affects microwave dielectric efficiency

2) Sol gel method The sol sol method uses a metal complex solution and an inorganic salt to form a transparent solution at a specific pH value, and then calcines to remove the organIC components, so as to obtain uniform, extremely fine particle raw powder, which greatly improves the homogeneity and density of ceramic components, greatly reduces the sintering temperature of ceramics, shortens the sintering cycle, and can reduce or avoid the formation of the second phase. However, This is conducive to improving data. The powder cost is relatively high. This process is very complex, the process parameters are difficult to control, the production cycle is long, and it is difficult to realize industrialization

3) Hydrothermal method The hydrothermal method is the reaction carried out in a seaLED pressure vessel. With the aqueous solution as the medium, the formation of the powder has gone through the process of dissolution to crystallization. No expensive alkoxide is required. Many materials can be directly synthesized at low temperatures to avoid grain growth, defects and impurities caused by aging

4) Precipitation method Precipitation method uses the solution metal salts of each component element to form a solution in a certain precipitation Homogeneous oxide mixture was obtained after calcination The method is simple, easy to scale production and low cost, but agglomeration or uneven composition will affect the dielectric efficiency

The preparation of powder materials is technically difficult For example, hydrothermal methods using barium carbonate as raw material include dissolution, titanium acylation, drying, dehydration, and re drying processes Unreasonable acid-base control and impurity generation will damage the powder Quality ultimately affects the performance of the screening program

3. Material requirements for 5G ceramic dielectric filters

Microwave dielectric ceramics are widely used. Because of their good microwave dielectric efficiency, such as low high frequency dielectric loss, medium dielectric constant, and low temperature coefficient of resonance frequency, they can be used as dielectric substrates, dielectric antennas, dielectric resonators, and dielectric filters

The electromagnetic wave resonance in 5G ceramic dielectric filter occurs in the ceramic dielectric materials. In retrOSPect, higher requirements are put forward for the efficiency of microwave dielectric ceramic materials The dielectric properties of microwave ceramics are mainly dielectric constant, quality factor Q, and harmonic frequency temperature Three coefficients:

1) Suitable dielectric constant; High dielectric constant can realize the filter size and miniaturization design, but the higher the dielectric constant is, the better it is, and the higher the dielectric constant will affect the transmission loss. Therefore, it is necessary to consider the design requirements of the filter to select the appropriate dielectric constant The dielectric constant of microwave dielectric ceramics mainly depends on the crystal phase in the data structure and the preparation process

2) High quality factor Q, low dielectric loss; The higher the quality factor Q, the narrower the passband, the better the circuit selectivity, and the better the filtering function The value of Q is inversely proportional to the dielectric loss tan 206,206Î The larger the Q value, the lower the insertion loss of the filter The data structure is uniform, high density, uniform grain growth, and the Q value can be increased by reducing impurities and defects

3) Near-zero adjustable temperature coefficient of resonance frequency. The temperature coefficient of the resonant frequency is close to zero to achieve high stability and reliability of the filter The temperature coefficient of frequency is mainly determined by the linear expansion coefficient and dielectric constant of the data

Ceramic powder determines the efficiency of dielectric filter, and its formulation and preparation are more difficult Only with good formula, we can obtain high Q dielectric ceramics under certain conditions It can be said that our own powder formula is the core competitiveness of ceramic screening program manufacturers The manufacturer of the screening procedure of powder preparation can prepare the preparation by itself by purchasing raw materials to avoid purchasing from the powder manufacturer, which not only saves costs, but also makes it easier to adjust the relevant parameters of the screening procedure according to the customized requirements of customers

The above is the explanation given by the editor of PCB circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.