Causes and Solutions of PCB Heating

Causes and solutions Printed circuit board heating

The electronIC equipment generates heat during operation, which makes the internal temperature of the equipment rise rapidly The direct cause of temperature rise is whether there are power consumption devices in PCB circuits The power consumption of electronic equipment varies The heating intensity varies with the power consumption If the heat is not dissipated in time, the equipment will continue to heat up, the equipment will become invalid due to overheating, and the reliability of electronic equipment will decline Therefore, heating furnace is very important for PCB

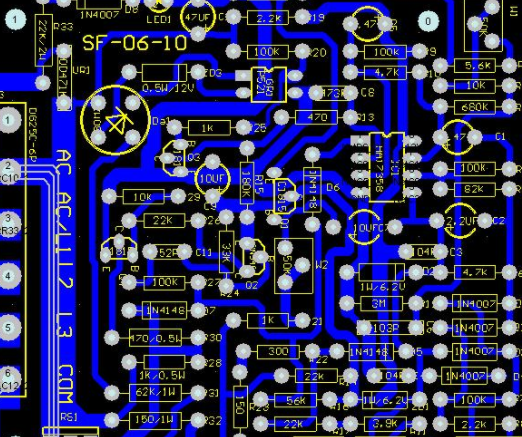

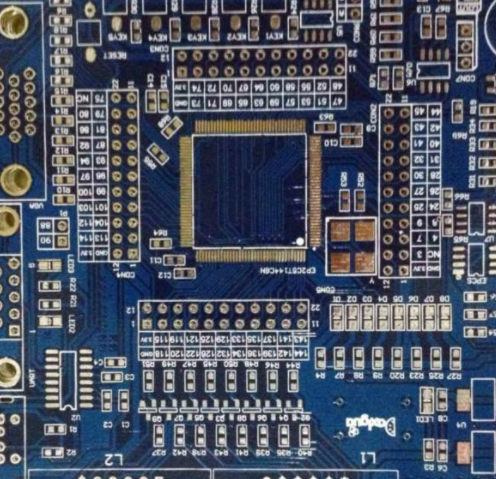

PCB heating

How to solve the heating problem of PCB? These problems are usually solved by adding a heat sink or fan to cool the PCB. These external accessories increase the cost and extend the manufacturing time. Adding fans in the design will also bring instability to the reliability. In this case, the printed circuit board mainly adopts active cooling rather than passive cooling

There are several ways to heat this PCB for your reference:

1. Heat conduction printed circuit board itself

2. Add radiator and heat conduction plate to the high heating device

3. Adopt reasonable wiring design to realize heat dissipation

4. Temperature sensitive equipment should be placed in the area with the lowest temperature (such as the bottom of the equipment). Do not place it directly above the heating device. It is better to stagger multiple equipment on a horizontal plane.

5. The heat dissipation of the printed board in the equipment mainly depends on the air flow. In retrOSPect, when designing and installing the equipment, it is necessary to study the air flow path. The printed circuit board should be reasonably configured

6. Avoid concentrating hot spots on the printed circuit board of the machine, evenly distribute power to the printed circuit board of the engine as much as possible, and maintain data consistency and consistent surface temperature efficiency of the printed circuit board

7. The equipment with the highest power consumption and maximum heat production shall be arranged near the optimal heat dissipation position

8. For equipment cooLED by free convection air, it is better to arrange the integrated circuits (or other devices) in a longitudinal manipulator or in a transverse manipulator

9. Devices on the same printed board shall be arranged in zones according to their calorific value and heat dissipation degree as far as possible. The equipment with low heating value or poor heat resistance shall be placed at the top airflow (inlet) of the cooling airflow, and the equipment with high heating value or good heat resistance (such as power transistors, large integrated circuits, etc.) shall be placed at the bottom airflow of the cooling airflow.

10. In the horizontal direction, the high-power device should be as close to the edge of the printed board as possible to shorten the heat transfer path; In the vertical direction, high-power equipment should be as close to the top of the printed board as possible to reduce the impact of these equipment on the temperature of other equipment.

11. When the high heat sink is connected to the base plate, the thermal resistance between them should be reduced as much as possible. In order to better meet the requirements of thermal characteristics, some thermal conductivity materials (such as coating a layer of thermal conductive silicone adhesive) can be used at the bottom of the chip, and a certain contact area can be maintained to facilitate heat dissipation of the device.

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.