High frequency PCB board interference problems and solutions

1 Power supply noise

In the high frequency PCB board, the noise of the power supply versus the high frequency signal Therefore, first of all, the power supply requires low noise Here, clean ground is as important as clean electrICity. Why?? Power supply characteristics are shown in Figure 1 Obviously, the power supply has a certain impedance, which is distributed on the whole power supply, and this noise will also be superimposed on the power supply Then we should reduce the impedance of the power supply as much as possible. There must be a dedicated power layer and ground plane In the high-frequency circuit design, the power supply is designed hierarchically, which is much better than the bus in most cases, so that the loop can always follow the path of impedance In addition, the power board must provide a signal loop for all generated and received signals on the PCB. It can reduce signal loops and noise, which is often ignored by low-frequency circuit designers

PCB board

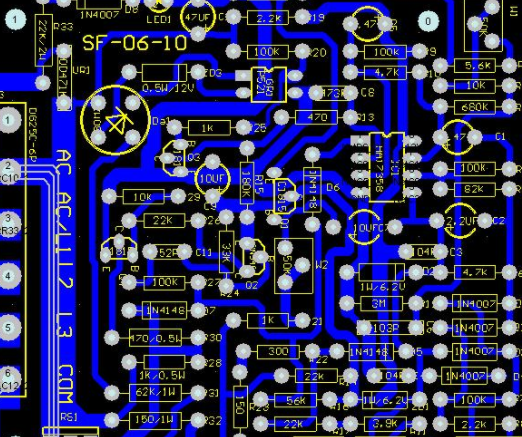

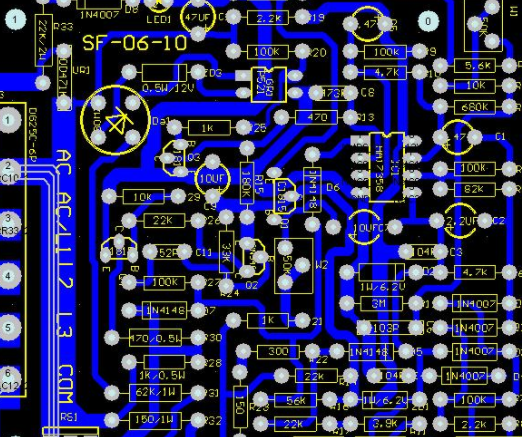

There are several ways to eliminate PCB design

1.1 Pay attention to the through-hole on the circuit board: the through-hole makes it necessary to etch the opening on the power board to leave space for the through-hole to pass through If the opening of the power layer is too large, it will inevitably affect the signal loop. The signal will be forced to bypass, the loop area will increase, and the noise will increase At the same time, if some signal lines are concentrated near the opening and share the loop, the common impedance will cause crosstalk

1.2 The connecting wire should have enough ground wires: each signal should have its own special signal loop, and the loop area of the signal and loop should be as SMAll as possible, that is, the signal and loop should be parallel

1.3 The power supply of analog power supply and digital power supply should be separated: high-frequency equipment is usually very sensitive to digital noise, so the two should be separated and connected together at the power inlet Place the circuit where the circuit area is reduced

1.4. Avoid overlapping of independent power supply between layers: otherwise, circuit noise is easily coupLED through parasitic capacitance

1.5 Isolation sensitive element: such as PLL

1.6 Placing the power cable: reduce the signal circuit, and reduce the noise by placing the power cable on the side of the signal cable

2. Transmission line

There are only two kinds of transmission lines that can appear in the PCB: strip line and microwave line. The problem with transmission lines is reflection, which can cause many problems For example, the load signal will be the superposition of the original signal and the echo signal, which increases the difficulty of signal analysis; Reflections cause return loss (return loss), which affects the signal as badly as additive noise interference:

2.1 Making it more noise for the receiver to distinguish the noise from the signal;

2.2 Any reflected signal will basically reduce the signal quality and change the shape of the input signal In principle, the solution is mainly impedance matching (for example, the impedance of the connection should be very matched with the impedance of the system)

2.3 Methods for eliminating interference of transmission lines PCB board design is as follows:

1) Avoid impedance discontinuities in the transmission line. Discontinuous impedance points are abrupt points of transmission lines, such as right angles, vias, etc, Avoid as much as possible The method is: avoid the right angle of the track, and try to take 45 ° angle or radian. Large angle is also acceptable; Use as few vias as possible, because each vias is a discontinuous impedance point, and the outer signal shall not pass through the inner layer, and vice versa

2) Do not use stake lines. Because any stub is a source of noise If the short circuit conductor is short circuited, it can be terminated at the end of the transmission line; If the short conductor is very long, the main transmission line will be used as the power supply, resulting in greater reflection, which will complicate the problem and is not recommended

3. Coupling

3.1 Common impedance coupling: it is a common coupling channel, that is, the interference source and the shared device of some conductors (such as loop power supply, bus, common point, etc.)

3.2 Field common mode coupling will cause the radiation source to generate common mode voltage on the loop formed by the disturbed circuit and the common reference plane The value of the common mode voltage generated in the series ground loop is Vcm=- (â ³ B/â ³ t)*area (â ³ B=change in the magnetic induction intensity in the formula) If it is an electromagnetic field, when its induced voltage: Vcm=(L * h * F * E)/48, the formula is applicable to L (m)=150MHz or less, the calculation of induced voltage can be SIMplified as: Vcm=2 * h * E

3.3 Differential mode field coupling: refers to the direct radiation received by the wire pair or wire and its loop on the circuit board If it is as close to two wires as possible This coupling is greatly reduced. In retrOSPect, two wires are wound together to reduce interference

3.4 Coupling between lines (crosstalk) can make any line equal to the unspecified coupling between parallel circuits, which will seriously damage the system efficiency Its types can be divided into capacitive crosstalk and inductive crosstalk The former is to couple the noise on the noise source to the noise receiving line by injecting current due to the parasitic capacitance between lines; The latter can be considered as unwanted signal coupling between the primary and secondary of parasitic transformers The magnitude of induced crosstalk depends on the proximity of the two loops, the size of the loop area, and the impedance of the affected load

3.5 Power line coupling: refers to the transmission of interference to other equipment by power lines after AC or DC power lines are subject to electromagnetic interference

3.6 There are several methods to eliminate PCB design:

1) The magnitude of both types of crosstalk increases with the increase of load interference

2) Increasing the distance between signal lines as much as possible can effectively reduce capacitive crosstalk. Space between traces (such as isolation of active signal lines and ground lines, especially between signal lines and ground where state transitions occur) and reduce lead induction

3) Inserting a ground wire between adjacent signal wires can also effectively reduce capacitive crosstalk. This ground wire needs to be connected to the ground plane/4 wavelength every 1 second

4) For inductive crosstalk, the circuit area shall be reduced as much as possible, and if allowed, the circuit shall be eliminated

5) Avoid signal sharing loops.

6) Focus on signal integrity: Designers address signal integrity by implementing termination during the soldering process. Designers using this method can focus on the microstrip length of the mask copper foil to obtain good signal integrity performance For systems that use dense connectors in communication structures, designers can use a single PCB for termination

4. Electromagnetic Interference

As speed increases, EMI will become more severe and manifest in many ways (such as electromagnetic interference at interfaces)

There are several ways to eliminate PCB design:

4.1 Reducing loops: Each loop is equivalent to an antenna, so we need to minimize the number of loops, loop area and loop antenna effect Ensure that there is only one loop at any two points of the signal, avoid artificial loop, and use the power panel as much as possible

4.2 Filtering: filtering can be used for power lines and signal lines to reduce electromagnetic interference There are three methods: decoupling capacitors, EMI filters, and magnetIC components

4.3 Mask Because of the space problem and many articles discussing masks, I will not introduce them in detail

4.4 Minimize high-frequency equipment

4.5 The dielectric constant PCB board of the newly added medium can prevent high-frequency components such as transmission lines close to the circuit board from radiating outwards; The newly added PCB board minimizes the thickness of microstrip line to prevent electromagnetic wire from overflowing and radiation

5. We should follow the following principles:

5.1 Uniformity and stability of power supply and grounding

5.2 Careful wiring and correct termination can eliminate reflection

5.3 Careful wiring and proper termination can reduce capacitance and inductance crosstalk

5.4 High frequency PCB board shall be suppressed to meet EMC requirements