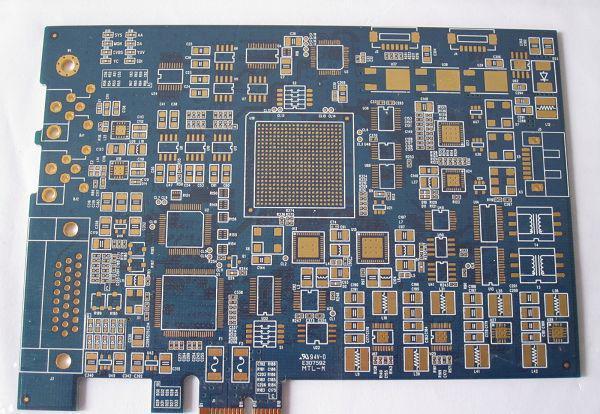

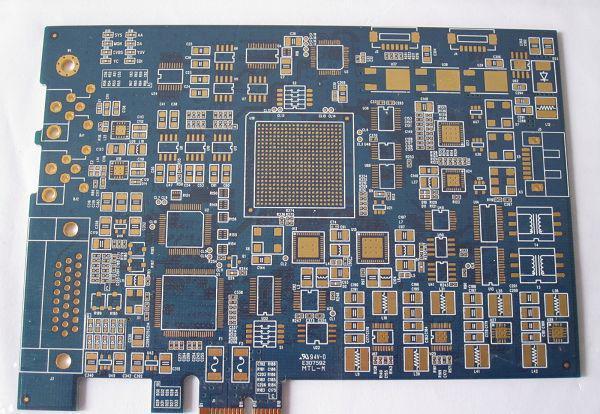

PCB layers, rules, component layout and fanout of pcb proofing

Although the current EDA tools for PCB proofing are very powerful, with the SMAller and smaller PCB size requirements, the higher and higher devICe density, the difficulty of PCB design is not small. How to achieve high PCB routing rate and shorten the design time? This paper introduces the design skills and key points of PCB planning, layout and routing. Now the time for PCB design is getting shorter and shorter, the smaller and smaller PCB space, the higher and higher device density, the extremely strict layout rules and large size components make the work of designers more difficult. In order to solve the design difficulties and speed up the launch of products, many manufacturers now tend to use special EDA tools to achieve PCB design. However, the special EDA tool can not produce ideal results, nor can it achieve 100% of the deployment rate, and it is very messy, and it usually takes a lot of time to complete the rest of the work.

There are many popular EDA tool software on the MARKet, but they are almost the same except for the different terminology and function key positions. How can we use these tools to better realize PCB design? The careful analysis of the design and the careful setting of the tool software before the start of wiring will make the design more consistent with the requirements. The following is the general design process and steps.

1. PCB proofing to determine the number of PCB layers

The size of the circuit board and the number of wiring layers need to be determined at the initial stage of design. If the design requires the use of high-density ball grid array (BGA) components, the minimum number of wiring layers required for the wiring of these devices must be considered. The number of wiring layers and the stacking up method will directly affect the wiring and impedance of the printed wire. The size of the board is helpful to determine the stacking mode and the width of the printed line to achieve the desired design effect.

For many years, people have always believed that the lower the number of circuit boards, the lower the cost. However, there are many other factors that affect the manufacturing cost of circuit boards. In recent years, the cost difference between multilayer boards has been greatly reduced. At the beginning of the design, it is better to use more circuit layers and make the copper coating evenly distributed, so as to avoid that a small number of signals do not meet the defined rules and space requirements when the design is near the end, so that new layers are forced to be added. Careful planning before design will reduce a lot of trouble in cabling.

2. Pcb proofing design rules and limitations

The auto routing tool itself does not know what to do. To complete the routing task, the routing tool needs to work under the correct rules and restrictions. Different signal lines have different wiring requirements. All signal lines with special requirements should be classified, and different design classifications are also different. Each signal class should have a priority. The higher the priority, the stricter the rules. The rules involve the width of printed wire, the maximum number of vias, parallelism, the interaction between signal wires, and layer restrictions. These rules have a great impact on the performance of wiring tools. Careful consideration of design requirements is an important step for successful cabling.

3. Layout of pcb proofing component

To optimize the assembly process, design for manufacturability (DFM) rules impose restrictions on component layout. If the assembly department allows the components to move, the circuit can be properly optimized to facilitate automatic wiring. The rules and constraints defined affect the layout design.

The routing channel and via area shall be considered in the layout. These paths and areas are obvious to designers, but the automatic routing tool will only consider one signal at a time. By setting the routing constraint conditions and setting the layers of signal wires that can be routed, the routing tool can complete the routing as envisioned by the designer.

4. design of PCB proofing fan out

In the fan out design stage, to enable the automatic wiring tool to connect the component pins, each pin of the surface mount device should have at least one via, so that when more connections are needed, the circuit board can conduct internal connection, online test (ICT) and circuit reprocessing.

In order to maximize the efficiency of the automatic routing tool, it is necessary to use the largest via size and printed wire as much as possible, and it is ideal to set the spacing at 50mil. Use the type of vias that maximize the number of routing diameters. When fan out design is carried out, the problem of circuit online test should be considered. Test fixtures can be expensive and are usually ordered when they are about to go into full production. It is too late to consider adding nodes to achieve 100% testability.

After careful consideration and prediction, the design of circuit online test can be carried out at the initial stage of design and realized at the later stage of production process. The type of via fan out can be determined according to the wiring path and circuit online test. The power supply and grounding will also affect the wiring and fan out design. In order to reduce the inductance generated by the connecting line of the filter capacitor, the vias should be as close to the pins of surface mount devices as possible. If necessary, manual wiring can be used. This may affect the originally envisaged wiring path, or even cause you to reconsider which vias to use. Therefore, the relationship between vias and pin inductance must be considered and the priority of vias specification must be set.