When you want to reduce PCB manufacturing costs, you usually need to seek the servICes of manufacturers. For high-quality price, high-quality service and high-quality service, you will understand that prefabricated houses are the best choice. But expensive manufacturers are not the only products that can reduce costs. The way you design electronic circuits has a great impact on costs. To understand how pcb design affects cost, let's study some important design elements to see how they affect PCB manufacturing cost.

Extend PCB manufacturing cycle

The faster you want PCB delivered to you, the higher the price you will pay. Sometimes you need to pay for short production cycles. At present, some manufacturers have the ability to send you a complete set of components within 24 hours, but the price is very expensive. A more cost-effective approach is a turnaround time of 20 days. By extending the manufacturing cycle so that you can accept longer lead times, you will significantly reduce manufacturing costs.

Do not specify pin free QFN and BGA

Bit manufacturing is widely packaged with BGA and QFN, including micro BGA with spacing as low as 0.3 mm. As the pins of these packages are located at the bottom, we must conduct X-ray inspection on each part, which will increase the cost of the manufacturing process. If you have to use needle free packaging, that's good. However, if you can use tssop or other software packages with visible prOSPects, your cost will be greatly reduced.

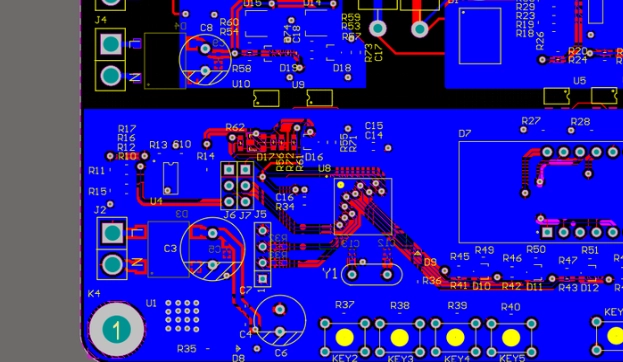

Pcb board making

Lower cost for scrollbars or continuous bars

Assemble any type of part or PCB of any size. However, it is cheaper to use drums or (at least) 12 inch continuous steel strips

surface mounting is cheaper than through-hole components

Manual assembly is usually more expensive than automatic assembly. Therefore, surface mount components are generally cheaper than through hole components. For designs with a SMAll number of through-hole parts, you can save money by manufacturing SMT chip processing parts or Minghua Avionics immersion welding through-hole parts.

Large PCBs are cheaper than very small PCBs

Large PCBs are easier to assemble than very small PCBs, so they are cheap and easy to assemble,. If you need to use micro PCBs (that is, less than 16 square inches), it is wise to splice them to reduce costs.