What is SMT processing and improving productivity

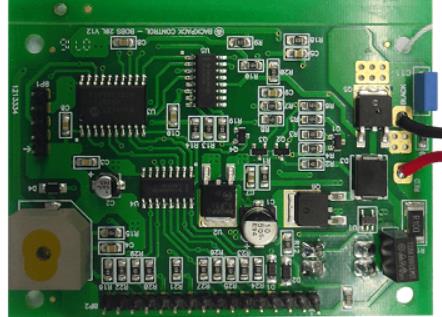

SMT processing refers to that electronIC customers provide PCB processing and production materials to electronic processors due to their lack of equipment and scientific and technological experience This is also the electronic processing service required by most electronic developers, which saves a lot of capital investment and factory rent for electronic developers, which undoubtedly reduces production costs and adds additional value to products Lingxinte Technology is a chip processing manufacturer with more than ten years of processing experience Strictly implement ISO9001 international production standard It specializes in providing various electronic processing services, such as PCBA processing, SMT patch, DIP parts and finished components Your pursuit of quality is our production standard

SMT processing flow

1. The two parties conducted detaiLED negotiations on the processing project, and signed a cooperation contract after confirmation.

2. The customer submits PCB files, BOM and parts data, etc This PCB file BOM is used to confirm the installation direction of components and the accuracy of data;

3. Incoming inspection and processing. IQC test data to ensure production quality. Some parts need to be processed, such as data trimming, part molding, etc.;

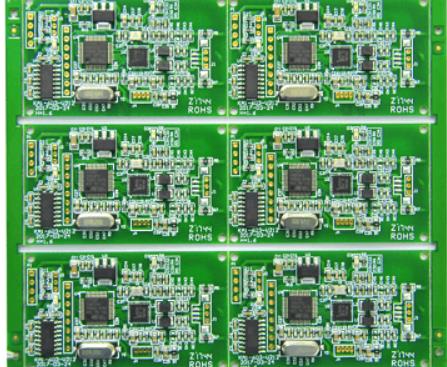

4. Online production. The first article shall be checked before going online, and mass production shall be carried out after confirmation by both parties. In this process, mold production, solder paste printing, component placement, reflow soldering and red glue process will be carried out;

5. Finished product inspection. The products shall be sent to the Quality Department for sampling inspection, and shall be packaged and shipped after the power supply is qualified.

How to improve the chip production efficiency

SMT patch processing efficiency has many aspects. For example, if the overall production capacity remains unchanged and the number of SMT SMT production lines is large, the production speed can also be improved. However, operating costs are also increasing. Nowadays, the fierce competition in the electronic industry is unimaginable. For the existing patch production line, we must improve the patch rate and win customer satisfaction. The factors influencing the placement rate of SMT and improvement measures are briefly introduced as follows:

SMT production line is mainly composed of screen printing machine, high-speed mounting machine, multi-functional mounting machine, reflow welder and AOI automatic detector. If two placement machines complete one placement process and the time (hereinafter referred to as placement time) is not equal, the placement rate will be affected. Specific methods:

1. Balance load distribution. Reasonably allocate the number of two placement elements to achieve load balanced distribution, so that the placement time of two placement machines is the same;

2. SMT mounter itself. We all know that SMT placement machine itself has a maximum placement speed value, but it is usually not easy to reach this value. This has a certain relationship with the structure of SMT mounter. For example, the X/Y structure of the mounter takes the measure of making the mounter pick up elements at the same time as much as possible. On the other hand, when arranging placement programs, the same types of components are arranged together to reduce the number of nozzle changes when placing the head to pick up components. Save installation time.

This SMT production line consists of many equipments If any device is processing, if the speed is slow, it will delay the placement time and affect the entire processing process How to improve is not only guided by theory, but also benefits from the rich experience of field operators

SMT processing refers to that electronIC customers provide PCB processing and production materials to electronic processors due to their lack of equipment and scientific and technological experience This is also the electronic processing service required by most electronic developers, which saves a lot of capital investment and factory rent for electronic developers, which undoubtedly reduces production costs and adds additional value to products Lingxinte Technology is a chip processing manufacturer with more than ten years of processing experience Strictly implement ISO9001 international production standard It specializes in providing various electronic processing services, such as PCBA processing, SMT patch, DIP parts and finished components Your pursuit of quality is our production standard

SMT processing flow

1. The two parties conducted detaiLED negotiations on the processing project, and signed a cooperation contract after confirmation.

2. The customer submits PCB files, BOM and parts data, etc This PCB file BOM is used to confirm the installation direction of components and the accuracy of data;

3. Incoming inspection and processing. IQC test data to ensure production quality. Some parts need to be processed, such as data trimming, part molding, etc.;

4. Online production. The first article shall be checked before going online, and mass production shall be carried out after confirmation by both parties. In this process, mold production, solder paste printing, component placement, reflow soldering and red glue process will be carried out;

5. Finished product inspection. The products shall be sent to the Quality Department for sampling inspection, and shall be packaged and shipped after the power supply is qualified.

How to improve the chip production efficiency

SMT patch processing efficiency has many aspects. For example, if the overall production capacity remains unchanged and the number of SMT SMT production lines is large, the production speed can also be improved. However, operating costs are also increasing. Nowadays, the fierce competition in the electronic industry is unimaginable. For the existing patch production line, we must improve the patch rate and win customer satisfaction. The factors influencing the placement rate of SMT and improvement measures are briefly introduced as follows:

SMT production line is mainly composed of screen printing machine, high-speed mounting machine, multi-functional mounting machine, reflow welder and AOI automatic detector. If two placement machines complete one placement process and the time (hereinafter referred to as placement time) is not equal, the placement rate will be affected. Specific methods:

1. Balance load distribution. Reasonably allocate the number of two placement elements to achieve load balanced distribution, so that the placement time of two placement machines is the same;

2. SMT mounter itself. We all know that SMT placement machine itself has a maximum placement speed value, but it is usually not easy to reach this value. This has a certain relationship with the structure of SMT mounter. For example, the X/Y structure of the mounter takes the measure of making the mounter pick up elements at the same time as much as possible. On the other hand, when arranging placement programs, the same types of components are arranged together to reduce the number of nozzle changes when placing the head to pick up components. Save installation time.

This SMT production line consists of many equipments If any device is processing, if the speed is slow, it will delay the placement time and affect the entire processing process How to improve is not only guided by theory, but also benefits from the rich experience of field operators

Gerberファイル、BOMファイル、および設計ファイルをアップロードするだけで、KINGFORDチームは24時間以内に完全な見積もりを提供します。