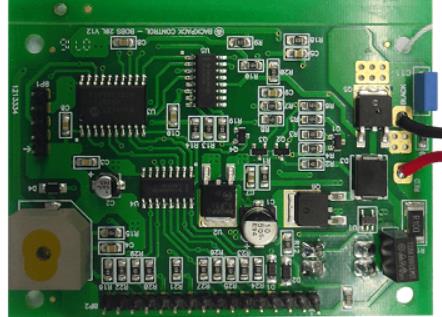

PCBA processing cost and SMT chip processing and welding

If you want to know about PCBA processing, you need to break down the whole process of packaging labor and materials PCBA (PCB assembly) means PCB assembly, so it must include circuit boards and lighting boards. Component welding (SMT surface mount/DIP plug-in post welding) These two parts. The prICes of optical boards and components in the MARKets of major shopping malls are basically open and transparent, which can be used for reference

Since the price of the main PCB and components is unlikely to rise in the dark, this cost is reflected in the assembly process. The main costs of this link include the following four aspects:

1. Auxiliary materials: solder paste, tin bar, flux, UV glue, furnace clamp

The quality of solder paste and solder rod is the most important auxiliary material in the whole processing link. Generally speaking, the price of domestic solder paste is 180~2.60 bottles, while that of imported solder paste may be 320~480 bottles. In the same welding area, the price of imported solder paste is much higher, but the difference in welding quality is very obvious.

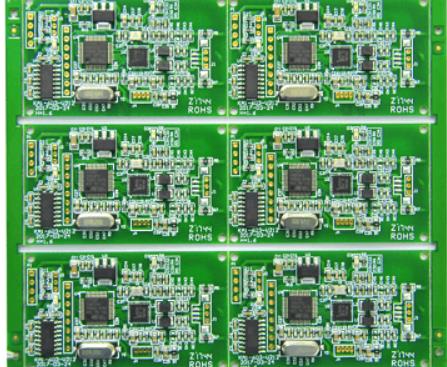

2. chip processing

The chip processing varies according to the number of points and packaging, and the price will also vary. Large quantity and high price are the consensus of the industry. The larger the package size is, the easier it is to install, and the corresponding inferior quality will be reduced. In this regard, there is more room for communication on price.

The connection of parts data involves the forming of special-shaped parts and data. This link requires a lot of manual participation. Because there is no reference to the production capacity of mechanical equipment, this link is the most difficult to control. At the same time, the labor cost is still very high, and the cost of this link is generally high.

Assembly test: test fixture, test equipment, test man hour

According to the difficulty of the test, the current price of the test fixture varies from tens of dollars to hundreds of dollars, while the test of communication equipment requires the assistance of optical fiber, ICT and other test equipment. The corresponding labor and equipment losses need to be considered, but not very high. Some companies even test for free.

How to avoid the defects in SMT chip processing and welding

Welding is the most important link in welding SMT patch processing If the welding link is not well done, it will affect the entire production of PCB If it is a little bit, there will be unqualified products. If the situation is serious, the products will be scrapped In order to avoid the influence on quality, it is necessary to pay attention to welding due to poor welding during SMT processing

Weld the heating bridge. The purpose of welding heat bridge in SMT process is to prevent solder from forming bridge. If an error occurs during this process, it will result in uneven solder distribution. The correct welding method is to place the tip of the soldering iron between the pins of the bonding pad and make the welding wire close to the tip of the soldering iron. When the solder paste melts, move the welding wire between the pad and the pin, and place the soldering iron on the welding wire. In this way, good solder joints can be produced and the influence on processing can be reduced.

2. The pin is firmly welded In the process of processing, excessive force during pin welding may easily lead to problems such as tilt, delamination or depression of the patch gasket Therefore, in order to ensure the quality of SMT patch welding process, it is not necessary to use too much force, only the soldering iron head needs to contact with the pad

Third, the choice of soldering head. In the welding process, the size of the tip of the soldering iron is also very important. If the size is too SMAll, the retention time of the tip of the soldering iron will increase, resulting in cold solder joints. Excessive size will lead to excessive heating and burn out of the patch. In this case, we need to select the size suitable for the soldering head according to its length and shape, as well as its heat capacity and contact surface.

4、 Temperature setting. Temperature is also a very important step in the welding process. If the temperature is set too high, the pad will tilt, and if the solder is overheated, the patch will be damaged. It is necessary to pay attention to the temperature setting. Setting the appropriate temperature is also particularly important for the processing quality.

5. Use of flux. During the implementation of relevant processes, if too much flux is used, it will lead to the problem of whether the lower weld leg is stable. If it is serious, corrosion or electron transfer may occur.

Transfer welding operations. Transfer welding refers to placing the solder on the top of the soldering iron and then transferring it to the connection. Improper operation will lead to poor wetting. In this case, we should first place the soldering head between the pad and the pin. When the iron wire is close to the tip of the iron, move the iron wire to the other side and wait for the tin to melt. Then place the tin wire between the pad and the pin. Place the soldering iron on the tin wire. When the tin melts, move the tin wire to the other side.

Modify or rework. The biggest taboo in the connection process is to polish or rework for the sake of perfection. This method is not only necessary for repeated modification or rework in pursuit of perfect product quality, but also easy to lead to metal layer fracture of circuit/pcb circuit board.

If you want to know about PCBA processing, you need to break down the whole process of packaging labor and materials PCBA (PCB assembly) means PCB assembly, so it must include circuit boards and lighting boards. Component welding (SMT surface mount/DIP plug-in post welding) These two parts. The prICes of optical boards and components in the MARKets of major shopping malls are basically open and transparent, which can be used for reference

Since the price of the main PCB and components is unlikely to rise in the dark, this cost is reflected in the assembly process. The main costs of this link include the following four aspects:

1. Auxiliary materials: solder paste, tin bar, flux, UV glue, furnace clamp

The quality of solder paste and solder rod is the most important auxiliary material in the whole processing link. Generally speaking, the price of domestic solder paste is 180~2.60 bottles, while that of imported solder paste may be 320~480 bottles. In the same welding area, the price of imported solder paste is much higher, but the difference in welding quality is very obvious.

2. chip processing

The chip processing varies according to the number of points and packaging, and the price will also vary. Large quantity and high price are the consensus of the industry. The larger the package size is, the easier it is to install, and the corresponding inferior quality will be reduced. In this regard, there is more room for communication on price.

The connection of parts data involves the forming of special-shaped parts and data. This link requires a lot of manual participation. Because there is no reference to the production capacity of mechanical equipment, this link is the most difficult to control. At the same time, the labor cost is still very high, and the cost of this link is generally high.

Assembly test: test fixture, test equipment, test man hour

According to the difficulty of the test, the current price of the test fixture varies from tens of dollars to hundreds of dollars, while the test of communication equipment requires the assistance of optical fiber, ICT and other test equipment. The corresponding labor and equipment losses need to be considered, but not very high. Some companies even test for free.

How to avoid the defects in SMT chip processing and welding

Welding is the most important link in welding SMT patch processing If the welding link is not well done, it will affect the entire production of PCB If it is a little bit, there will be unqualified products. If the situation is serious, the products will be scrapped In order to avoid the influence on quality, it is necessary to pay attention to welding due to poor welding during SMT processing

Weld the heating bridge. The purpose of welding heat bridge in SMT process is to prevent solder from forming bridge. If an error occurs during this process, it will result in uneven solder distribution. The correct welding method is to place the tip of the soldering iron between the pins of the bonding pad and make the welding wire close to the tip of the soldering iron. When the solder paste melts, move the welding wire between the pad and the pin, and place the soldering iron on the welding wire. In this way, good solder joints can be produced and the influence on processing can be reduced.

2. The pin is firmly welded In the process of processing, excessive force during pin welding may easily lead to problems such as tilt, delamination or depression of the patch gasket Therefore, in order to ensure the quality of SMT patch welding process, it is not necessary to use too much force, only the soldering iron head needs to contact with the pad

Third, the choice of soldering head. In the welding process, the size of the tip of the soldering iron is also very important. If the size is too SMAll, the retention time of the tip of the soldering iron will increase, resulting in cold solder joints. Excessive size will lead to excessive heating and burn out of the patch. In this case, we need to select the size suitable for the soldering head according to its length and shape, as well as its heat capacity and contact surface.

4、 Temperature setting. Temperature is also a very important step in the welding process. If the temperature is set too high, the pad will tilt, and if the solder is overheated, the patch will be damaged. It is necessary to pay attention to the temperature setting. Setting the appropriate temperature is also particularly important for the processing quality.

5. Use of flux. During the implementation of relevant processes, if too much flux is used, it will lead to the problem of whether the lower weld leg is stable. If it is serious, corrosion or electron transfer may occur.

Transfer welding operations. Transfer welding refers to placing the solder on the top of the soldering iron and then transferring it to the connection. Improper operation will lead to poor wetting. In this case, we should first place the soldering head between the pad and the pin. When the iron wire is close to the tip of the iron, move the iron wire to the other side and wait for the tin to melt. Then place the tin wire between the pad and the pin. Place the soldering iron on the tin wire. When the tin melts, move the tin wire to the other side.

Modify or rework. The biggest taboo in the connection process is to polish or rework for the sake of perfection. This method is not only necessary for repeated modification or rework in pursuit of perfect product quality, but also easy to lead to metal layer fracture of circuit/pcb circuit board.

Gerberファイル、BOMファイル、および設計ファイルをアップロードするだけで、KINGFORDチームは24時間以内に完全な見積もりを提供します。