Hardware and software considerations of SMT mounter

No matter what machinery and equipment are used, they must be maintained This can not only maintain the stability and accuracy of the equipment, but also extend the servICe life of the equipment This SMT placement machine is no exception

Let's talk about the precautions for some objective factors of the mounter

Precautions:

- SMT mounter hardware

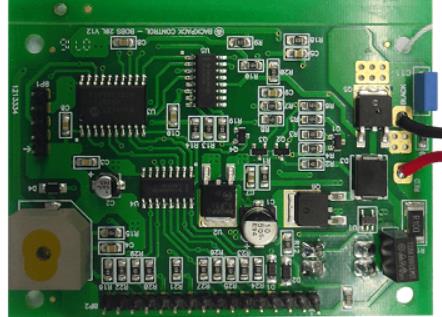

1. For power supply, it is recommended that all SMT machines be connected to the UPS and voltage regulator. The pollution of grid voltage will lead to voltage instability, resulting in circuit board burning, power failure will damage the computer hard disk, and there is a risk of scrapping the circuit board in the furnace.

2. The air source and compressed air must remove the dust and water drops on the board and drip them onto the sleeve and RV reading head, which leads to frequent reports of RVD, and the new machine will directly burn out the vacuum generator;

3. Temperature and humidity The optimum temperature for SMT equipment is 24 ± 4 ℃, and the humidity is 45% - 75% High temperature leads to equipment shutdown, various SMAll problems occur frequently, stuttering and low humidity will produce high static electricity Cause the throwing speed to increase

4. Cleanliness and SMT dust are very important to the quality of the furnace. Data above 0201 shall be operated in 30W dust-free workshop. High speed machines are afraid of dust. Large dust may cause suction nozzles. The flying material is blocked and leaks frequently. Secondly, it will affect various sensors, especially the BE sensor, which will lead to inaccurate measurement of the thickness of small data. Third, it is easy to accelerate the wear of sliding block and guide rail.

5. Dedusting of electric control part. In general, the equipment in the workshop for more than 3 years or with poor dust prevention environment shall be inspected and dedusted in the first quarter, and the new machine shall be inspected and dedusted once a year. Prevent the occurrence of defective equipment failures, such as insufficient heat dissipation, collision, circuit board burns and poor contact after circuit board looseness.

6. The skills of engineers are produced by many companies without good control over the above aspects. When purchasing the machine for the first time, there was no problem in the first two or three years. There are more and more follow-up problems, the quality is getting worse and worse, and the maintenance cost is getting higher and higher. Gao, the boss is unwilling to pay a high price for good professional equipment engineering. In case of any problem, no matter whether the equipment engineering technicians are qualified or not, the equipment engineering technicians will be removed. I pay several times the price of accessories

II SMT machine software

In terms of software, the main problems are viruses, where they come from, and USB flash drives. It is recommended to use LAN shared programs, or use high-end anti-virus write protect USB flash drives. Ordinary USB flash drives are used to control the risk of virus transmission and are also the number one source of viruses. The program is stored in the SQL database. Any problem caused by wired control poisoning will occur., For example, if the data is reversed for unknown reasons, when the line control changes, the program cannot take effect on the machine, the OIS cannot be connected, the image cannot be returned to the line control, the program cannot be transmitted to the machine, and so on.

The above is the explanation given by the editor of PCB circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.