SMT red glue knowLEDge and PCBA processing servICe

SMT patch red glue is a compound with multiple dilutions The difference between solder paste and solder paste is that solder paste will solidify after heating, and the freezing point temperature is 1.50 ℃. At this time, the red glue starts to directly change from paste to solid

SMT patch red adhesive has viscosity and fluidity, temperature characteristics, wetting characteristics, etc According to this characteristic of red glue, in production, the purpose of using red glue is to firmly stick components on the PCB surface to prevent them from falling

For use on printing presses or dispensers:

1. In order to maintain the quality of patch adhesive, please store it in the reflector (5 ± 3 degree Celsius);

2. Before taking out the freezer, it should be kept at room temperature for 2-3 hours;

3. Clean the hose with toluene or ethyl acetate. Dispensing: 1. Add a back plug on the distribution pipe to obtain more stable distribution;

2. The recommended distribution temperature is 30-35 ℃;

3. When subpackaging the dispensing hose, please use a special dispensing machine for subpackaging to prevent

Mix bubbles in the wiper: the recommended wiper temperature is 30-35 ℃. Note: Red

After the glue is taken out of the freezing environment, it cannot be opened for use until it reaches room temperature. Avoid pollution

When dyeing the original product, do not return any used repair glue to the original package.

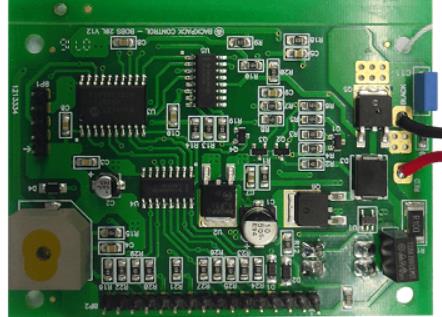

circuit board processing service

PCBA processing service starts from the production of PCB. Supported PCBA manufacturers (who have obtained the extremely strict TS16949 certification in the automotive industry) focus on the quality of PCB and PCBA quality control system With deCADes of experience in electronic component procurement, we have maintained long-term cooperation with large brands to ensure the original packaging and procurement access of components In the packaging process of components, Tamura and Loctite solder pastes from Japan are selected to ensure the reliability of welding, and automatic printing machine, 3-star high-speed mounting machine, up and down eight temperature zone reflow soldering, AOI automatic optical detector/X-ray BGA inspection machine, etc. can effectively ensure the reliability and quality of the electronic packaging process In addition, complete IPC, IPQC, OQA and other management processes, define work responsibilities, and strictly implement the acceptance standards of IPC electronIC components Regarding PCBA testing, we have professional engineers who use a variety of test racks to conduct 100% batch testing, including path, noise, amplitude, signal, temperature, humidity, drop, or execute the customer's detailed test plan All efforts are aimed at becoming a PCBA processing manufacturer

PCBA quotation needs to provide:

1. Complete PCB board production files (Gerber files, placement plans, wire mesh files) and board Production requirements;

2. Complete BOM (including model, brand, package, description, etc.);

3. PCBA assembly drawing.

PS: The test method shall be provided when reporting the test cost.

The above is the explanation given by the editor of PCB circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.