MRI equipment is another major advancement in medICal imaging after CT, and is the core technology of modern medical technology. MRI equipment is now SMAller, faster, and more accurate. The construction of these boards requires compliance with strict regulatory controls and inclusion of The design strategy of manufacturing problems, because it is related to life safety, the research and development of medical electronic equipment and the manufacture of PCBs, must be strictly required in all aspects of the supply chain of equipment, processes and components.

Therefore, when assembling the PCB of the NMR equipment, safety, reliability, compliance, cleanliness, etc. need to be considered in the design, manufacture, and assembly of the NMR equipment. When producing PCBs for NMR equipment, we will ensure that the NMR PCBs can still protect the safety of patients under extreme conditions such as high temperature or ultra-low temperature. High speed, high density, and high power need to be considered when designing NMR PCBs.

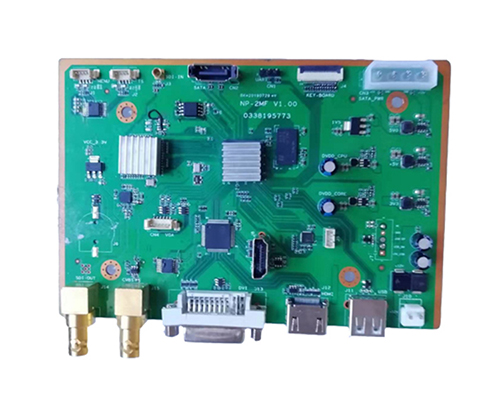

NMR equipment PCB assembly performance parameters:

Product application industry: medical electronic equipment

Product name: double-sided FR4, plate thickness 1.6MM, copper thickness 1OZ, immersion gold, blue oil white,

single piece size 19.1*31.75MM;

Inspection method: x-ray, AOI, SPI

Process flow: DIP + packaging

manufacturing process: lead soldering process

Types of electronIC components used in the board: PCB, plug-in IC, plug-in pins, plug-in resistors, plug-in magnetic beads

Kingford has more than 20 years of production experience in the field of medical devices. Choosing a PCB manufacturer who is proficient in high-Reliability PCB design and assembly experience can help reduce risks and improve product reliability.