ApplICation and characteristics of dust-free paper in SMT process

PCB manufacturers and PCB designers will explain the use and characteristics of dust-free paper in the SMT process.

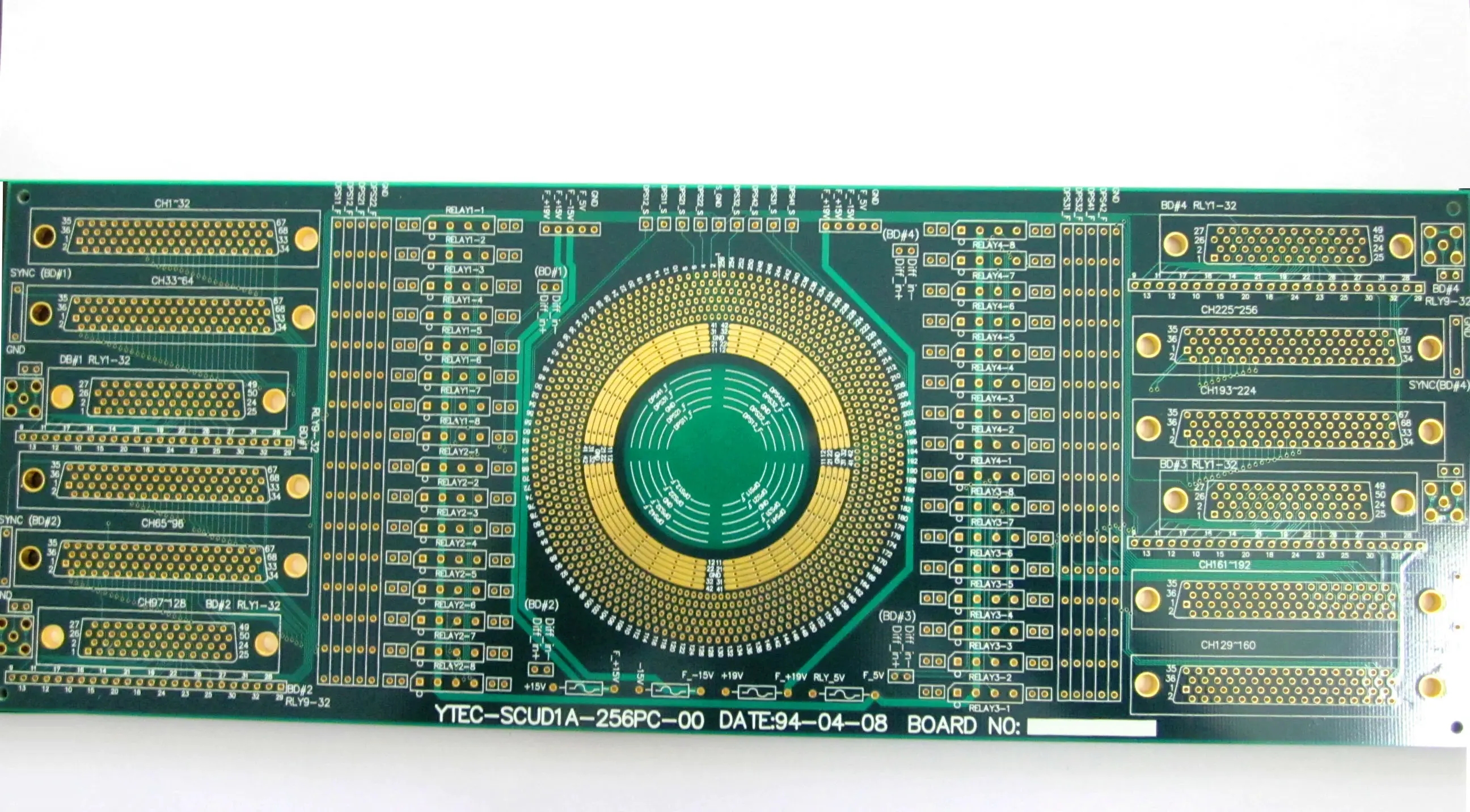

SMT process: short for Surface Mount Technology, SMT surface mount technology is an electronic assembly technology that originated in the 1960s, was initially developed by IBM in the United States, and then gradually matured in the late 1980s. SMT technology is to install electronIC components, such as resistors, capacitors, transistors, integrated circuits, etc. on printed circuit boards, and form electrical connections through lead soldering. The components used are also referred to as SMD (surface mount devices). The biggest difference between SMT and plug-in technology is that SMT surface adhesion technology does not need to reserve corresponding through holes for the pins of components, and the component size of surface adhesion technology is much SMAller than that of plug-in packaging. This SMT technology can greatly reduce the volume of electronic products to achieve the purpose of thin and short, referred to as SMT process.

Use and characteristics of dust-free paper

Dust free paper, also known as automatic wiping paper and steel mesh wiping paper, is calLED Airline Paper in English. Although it is called paper, it is essentially a non-woven cloth, which is made of 100% polyester fibers. Its surface is soft, easy to wipe sensitive surfaces, and does not remove fibers when rubbed. It has good water absorption and cleaning efficiency. It is cut by using high-pressure micro water needles to intertwine fibers in multiple layers of fibers, so as to consolidate them into cloth. It is widely used in SMT processing, and can be divided into nuclear industry dust-free paper, radiation proof dust-free paper, photoelectric dust-free paper, PCB dust-free paper, anti-static dust-free paper, conductive dust-free paper, etc.

1、 Use of dust-free paper

1. It is applicable to the cleaning of high standard surfaces. It is a special wiping product for SMT printing machines of circuit boards in the electronic industry

2. It can effectively remove the excessive solder paste, red glue and other adhesions on the printing machine steel mesh and circuit board

3. Excellent dedusting effect, anti-static function, high efficiency water absorption, soft and will not damage the surface of objects, suitable for dust-free purification workshop

2、 Characteristics of dust-free paper

1. Excellent dedusting effect

2. High water absorption

3. Provide sufficient dry and wet strength

4. Low ion release, not easy to cause chEMIcal reaction

5. No particles and thread ends will be left after wiping, with strong decontamination ability

PCB manufacturers and PCB designers will explain the use and characteristics of dust-free paper in the SMT process.