Purpose and precautions of PCBA repair and rework

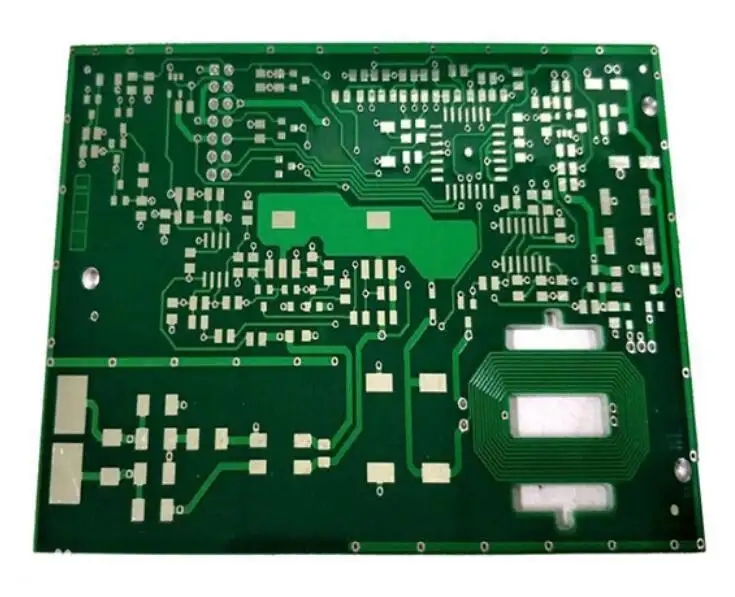

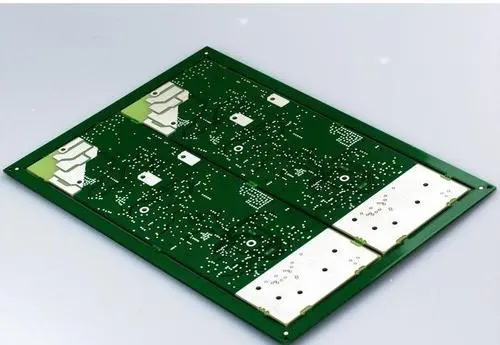

In the PCBA processing plant, there will be some defective products or boards that have problems and need to be repaired. How should PCBA boards be treated after welding or repair? 1、 Process purpose of PCBA repair and repair ① Open circuit, bridging, faulty soldering, poor wetting and other solder joint defects generated in reflow soldering and wave soldering processes need to be manually assisted with necessary tools

In the PCBA processing plant, there will be some defective products or boards that have problems and need to be repaired. How should PCBA boards be treated after welding or repair?

1、 Process purpose of PCBA repair and repair

① Solder joint defects such as open circuit, bridging, faulty soldering and poor wetting produced in reflow soldering and wave soldering processes need to be removed after manual repair with necessary tools (such as BGA repair bench, X-ray, high-power mICroscope), so as to obtain qualified pcba solder joints.

② Repair the missing components.

③ Replace the pasted position and damaged components.

④ There are also some components that need to be replaced after the debugging of the single board and the whole machine.

③ The complete machine shall be repaired after delivery.

Purpose and precautions of PCBA repair and rework

2、 Judge the solder joints to be repaired

(1) First of all, electronic products should be positioned: judge what kind of solder joints need to be repaired, first of all, electronic products should be positioned to determine which level the electronic products belong to. Level 3 is the highest requirement. If the product belongs to Level 3, it must be tested according to the highest standard, because the main goal of Level 3 products is reliability; If the product belongs to Level 1, it is OK to follow the lowest level standard.

(2) The definition of "excellent solder joint" shall be clarified: excellent SMT solder joint refers to the solder joint that can maintain the electrical performance and mechanical strength within the service environment, mode and service life considered in the design. Therefore, as long as this condition is met, it is not necessary to repair.

3、 Precautions for repair

① Do not damage the pad

② Availability of components. If it is double-sided welding, a component needs to be heated twice: if it is reworked once before leaving the factory, it needs to be heated twice (for disassembly and welding, it needs to be heated once respectively); if it is reworked once after leaving the factory, it needs to be heated twice again. According to this calculation, a component should be able to withstand 6 times of high temperature welding before it is qualified. Therefore, for high reliability products, components that may have been repaired once cannot be used again, otherwise reliability problems will occur

③ The component surface and PCB surface must be flat.

④ SIMulate the process parameters in the production process as much as possible.

⑤ Note the number of potential electrostatic discharge (ESD) hazards. ① The most important thing for repair is to follow the correct welding curve.