Inspection method and step requirements for the first PCBA board

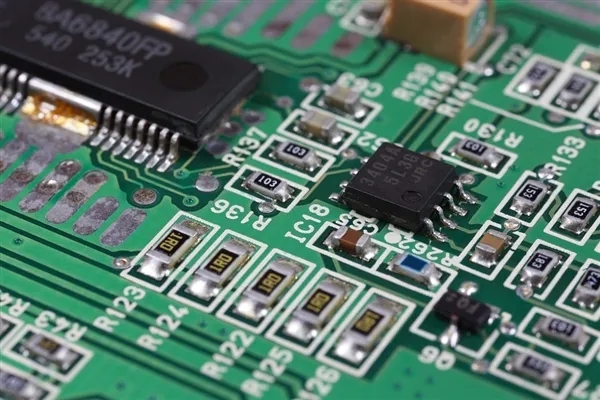

PCB (printed circuit board), namely printed circuit board, is one of the important components of the electronIC industry. Almost every kind of electronic equipment, from electronic watches and calculators to computers, communication electronic equipment, military weapon systems, as long as there are integrated circuits and other electronIC components, in order to make electrical interconnection between various components, printed boards are used. The printed circuit board is composed of an insulating base plate, a bonding pad for connecting wires and assembling and welding electronic

components. It has the dual functions of conducting lines and insulating base plates. It can replace the complex wiring and realize the electrical connection between the components in the circuit. It not only SIMplifies the assembly and welding of electronic products, reduces the wiring workload in the traditional way, and greatly reduces the labor intensity of workers; Moreover, the overall volume is reduced, the product cost is reduced, and the quality and reliability of electronic equipment are improved. Printed circuit board has good product consistency. It can adopt standardized design, which is conducive to mechanization and automation in the production process. At the same time, the whole printed circuit board after assembly and debugging can be used as an independent spare part to facilitate the exchange and maintenance of the whole machine. At present, printed circuit board has been widely used in the production of electronic products.

The first SMT product in the SMT industry is the first PCBA board that meets the welding quality requirements. It is possible to have batches of defects, repair or scrap during SMT chip processing. The first article inspection in the smt industry is to avoid such batches of defects during electronic processing, which is a means for electronic processing plants to control the product production process.

The first SMT product in the smt industry is the first PCBA board that meets the welding quality requirements. It is possible to have batches of defects, repair or scrap during SMT chip processing. The first article inspection in the smt industry is to avoid such batches of defects during electronic processing, which is a means for electronic processing plants to control the product production process.

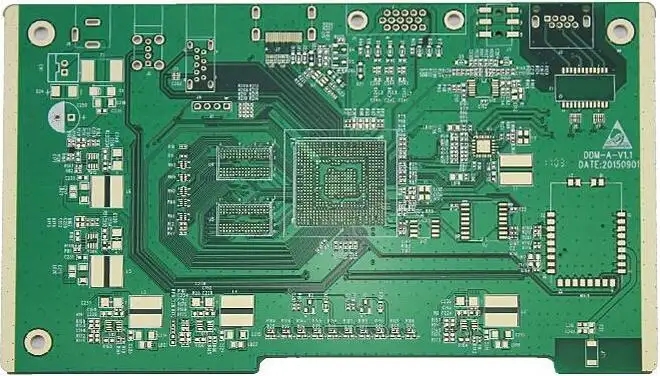

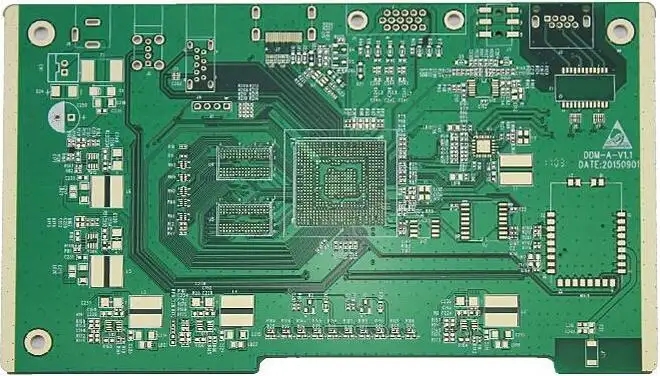

The welding process of the first PCBA board is probably that the boards passing the patch inspection are placed horizontally on the mesh conveyor belt or chain guide rail, and slowly enter the furnace with the conveyor belt according to the set speed level. After passing through the heating zone, insulation zone, reflux zone and cooling zone, the reflow welding of SMT patch processing is completed.

Inspection method and step requirements for the first PCBA board

First article inspection method: visual inspection method is generally adopted for the first article inspection in smt industry, and magnifying glass or microscope is selected for inspection according to the assembly density.

First article inspection content:

1. Whether the welding is sufficient.

2. Whether the welding spot surface is smooth, whether there are hole defects and the size of holes.

3. Whether the amount of solder is appropriate.

4. The number of tin balls and residues.

5. Rejection rate of standing stone, faulty welding, bridging, component displacement, etc.

6. PCB color change.