Short circuit prevention in SMT chip processing

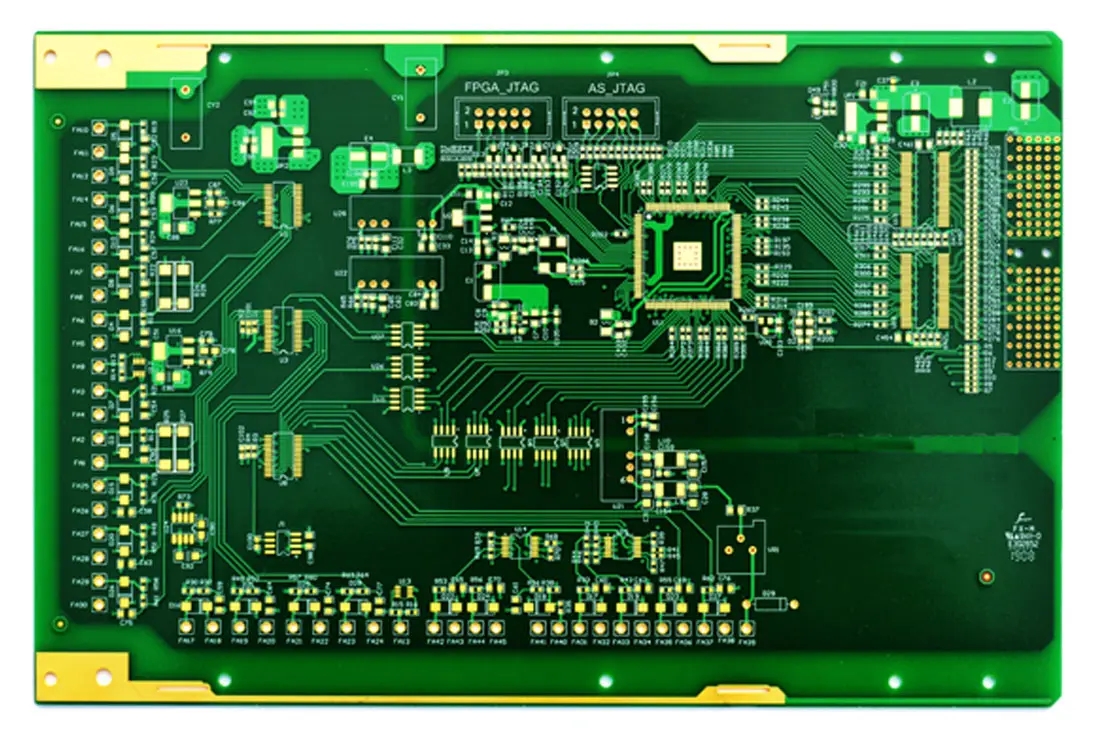

SMT chip processing: accurately install surface mounted components to the fixed position of PCB. The equipment used is the mounting machine, whICh is located behind the printing machine in the SMT production line. After using SMT, electronic products are SMAller in size, lighter in weight, higher in reliability and stronger in anti vibration ability. The solder joint defect rate is low. High frequency characteristics are good. Reduce electromagnetic and radio frequency interference. It is easy to realize automation and improve production efficiency. Save materials, energy, equipment, manpower, time, etc.

In the manual welding process of SMT patch, short circuit is a common processing defect. To achieve the same effect of manual SMT patch and machine patch, short circuit is a problem that must be solved. Short circuited PCBA cannot be used. There are also many ways to solve short circuit in SMT chip processing. Here is a brief introduction.

In the manual welding process of SMT patch, short circuit is a common processing defect. To achieve the same effect of manual SMT patch and machine patch, short circuit is a problem that must be solved. Short circuited PCBA cannot be used. There are also many ways to solve short circuit in SMT chip processing. Here is a brief introduction.

What are the methods to prevent short circuit in SMT chip processing

1. The manual welding operation should form a good habit. Use a multimeter to check whether the key circuit is short circuited. Every time the manual SMT placement is completed, use a multimeter to measure whether the power supply and ground are short circuited.

2. Light up the short circuit network on the PCB diagram, find the place on the circuit board where short circuit is most likely to occur, and pay attention to the internal short circuit of the IC.

3. If the short circuit occurs in the same batch during SMT chip processing, you can take a board to cut the wire, and then power on each part to check the short circuit

4. Use the short circuit positioning analyzer to check.

5. If there is a BGA chip, because all the solder joints are covered by the chip and cannot be seen, and it is also a Multilayer board (more than 4 layers), it is better to separate the power supply of each chip during the design, and connect it with a magnetic bead or a 0 ohm resistance. In this way, when the power supply is short circuited to the ground, disconnect the magnetic bead detection, and it is easy to locate a chip.

6. Be careful when welding the capacitance of the small SMT chip processing surface, especially the power filter capacitors (103 or 104), which are large in number, can easily cause short circuit between the power supply and the ground.