describe

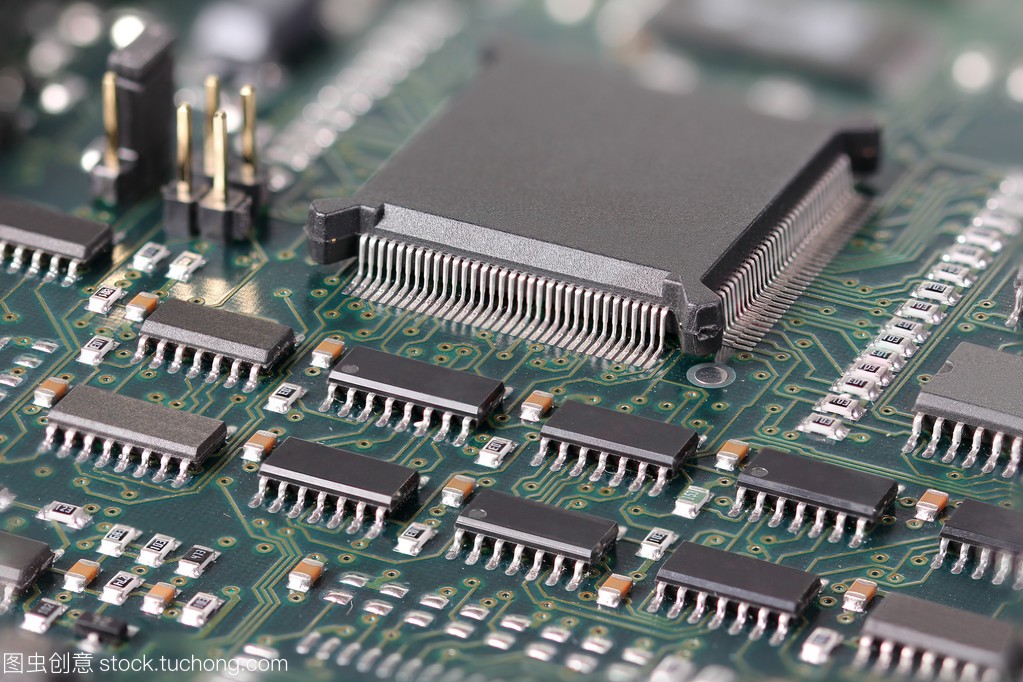

Most entrepreneurs and manufacturers find the old way of making electronICs and printed circuit board assemblies very intimidating because it is slow, error-prone and expensive. It is not designed for SMAll batch runs and prototyping, but to support large orders and require long lead times. Fortunately, Turnkey printed circuit board (PCB) assembly services are now meeting the needs of hardware designers.

What is a turnkey printed circuit board assembly?

A new approach to impact onshore electronic assemblies PCB manufacturing and cloud-based software provide entrepreneurs, manufacturers, engineers and small businesses with stress-free and fast emerging printed circuit boards. With this, you just upload the design in the file and immediately receive a quote, the manufacturer will take care of the rest.

Turnkey PCB assembly goes beyond just a board of some services and provides the necessary services to launch your finished product. Your product will be assembLED as needed and a record of your parts will be maintained.

An example of a company that offers turnkey PCB assembly is Belittle Electronics, which also assembles SMT designs.

Several Benefits of Turnkey PCB assembly

Hardware designers rejoice because Turnkey PCB assembly provides new opportunities. Some of these great opportunities include:

1. Instant Quote

The design of traditional PCB manufacturing methods does not increase the speed. Often, designers have to wait a long time just to know the cost of the order. But with the new Turnkey PCB components, this is not the case. Here, you can view the cost of your order as soon as the design file is uploaded to the seller's online portal.

2. Prototyping

The production of your first prototype is usually a very slow and expensive process. With this, chores like out-of-stock ingredients, slow delivery times, and keeping in touch with many sellers around the world become tedious. With Trunk PCB Assembly, you can now prototype more efficiently and effectively. It's never been easier to iterate on your product and get to MARKet quickly and cheaply.

3. Online ordering, tracking and reporting

Online portal for SIMplified document management, ordering and tracking for instant PCB assembly. You can log in and see the real-time status of your work, and you'll receive email notifications and alerts when work reaches key milestones.

4. A seller to manage

The turnkey approach to PCB construction means you don't have to worry about managing many sellers. This is especially beneficial if the seller has to assemble your final product. Miscommunication, delays, frustration and disappointment are problems of the past.

5. Order 1 or 10,000

Also known as Kick starter Makers or Cloud Makers, turnkey PCB assembly makers have systems that can bring together small orders and combine them into one big run. Once the design is perfect, your turnkey PCB assembly partner will be happy to manufacture your design in desired quantities. You can stay with the same partner as your business grows.

6. Delivery service, inventory and product assembly

Also, final shipping services, inventory and assembly, and products are made by top express PCB manufacturers. Without counting reels or touching boxes, you can ship materials and components, make complex products, and view your inventory. Certain vendors provide A Pis for integration with your e-commerce or ERP solutions. Customers' orders are shipped directly from the manufacturer without any stress or delays on your part.

Personnel who can use turnkey PCB assembly

Anyone with a design can come up with their new ideas quickly and cost-effectively because this new method of printed circuit board manufacturing removes the constraints inherent in quantity and cost. legacy system. For startups and small businesses that want to bring products to market without the risk and cost of large inventories, turnkey PCB assembly is just the go-to way to go. Also, it's beneficial for Kick starter makers who may not know if they only need hundreds or a few boards. Manufacturers and hobbyists also enjoy the flexibility and speed of instant PCB construction. Engineers at large enterprises also find it faster, easier and more attractive than traditional methods.

From concept to delivery

The producer controls the entire process through turnkey PCB assembly. The process includes component sourcing, PCB fabrication, packaging, PCB assembly, implementation and testing. When you have the right partner, you can eliminate the hassle of storing, buying and tracking inventory, along with the complexities and delays built into traditional methods. Now, while you focus on perfecting your design, you can let the PCB seller worry about other things.

The manufacture of modern PCB's is a good link between streamlined manufacturing and in-line technology. This makes it possible to get a prototype within days, ship a fully assembled product directly to the customer, and get a quote within minutes. As more innovative products and higher quality products enter the market with fewer barriers to creation, everyone benefits.