Composition and function of SMT head

From the perspective of robot concept, the SMT placement head is a SMArt manipulator Through program control, it will automatICally correct the position, pick up parts as needed, and accurately place them on the preset pad to complete 3D reciprocating motion It is the most complex and critical part of the placement machine The placement head consists of a suction nozzle, a visual calibration system, sensors and other components

There are two types of patch heads: single head and multi head. The multi head patch heads are divided into fixed type and rotary type. After the suction cup nozzle of the early single tip mounter sucked the components, the mechanical centering mechanism was used to realize the component centering, and send a signal to the feeder to make the next component enter the suction cup position. However, the installation speed of such pipes is very slow, and it usually takes 1s to place chip components. In order to improve the patch speed, people have adopted the method of increasing the number of patch headers, that is, using multiple patch headers to improve the patch speed. The multi tip mounter has been increased from single tip to 3. to 6 tips, instead of using mechanical alignment, it has been improved to multiple forms of optical alignment. Pick up components during work, and then place them on PCB in turn after alignment. In a designated position on the board of Directors. At present, the placement speed of such machines has reached the level of 30000 parts per hour, and the price of such machines is relatively low, which can be used in combination. You can also use a rotating multi head structure. At present, the repair speed of this method has reached 45000 to 50000 pieces per hour.

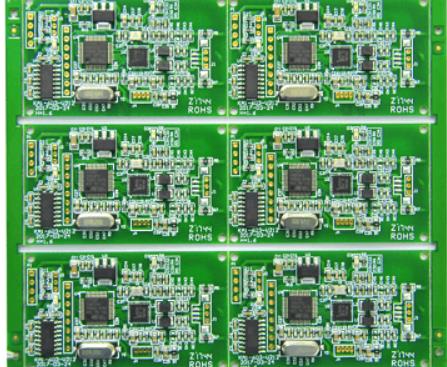

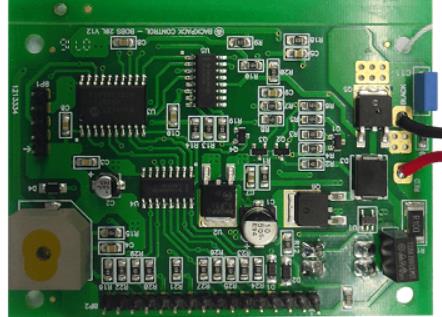

Circuit board

(1) Suction nozzle. At the end of the placement head is a placement tool controlLED by the vacuum pump, namely the suction nozzle. Parts of different shapes and sizes are usually picked up and placed with different nozzles. After the vacuum is generated, the negative pressure of the suction nozzle sucks the SMD components from the feeding system (bulk silos, tubular hoppers, disk tape or pallet packaging). The oil suction nozzle must reach a certain vacuum degree when absorbing the oil film. Only in this way can we judge whether the picked parts are normal. When the part is side standing or cannot be sucked out due to the part "cylinder", the mounter will give an alarm signal. When picking a nozzle pick component and placing it on a PCB, two methods are usually used for placement. One is based on the height of the component, that is, the thickness of the component is entered in advance. When the placement head drops to this height, the vacuum is released and the component is placed on the pad. In this method, due to individual differences of components or PCBs, early or late placement may occur, and in serious cases, component displacement or flyer defects may result. Another more advanced method is to realize soft landing under the action of pressure sensor based on the transient response of component and PCB contact. This placement is very easy, not easy to cause displacement and flyer defects.

The suction nozzle is a component that directly contacts the components. In order to adapt to the placement of different parts, many mounters are still equipped with a device to replace the suction nozzle There is also an elastic compensation buffer mechanism between the oil suction nozzle and the oil suction pipe to ensure the protection of SMT components during picking

The nozzle is in contact with the components in the high-speed movement process and is seriously worn. The information and structure of this nozzle are paid more and more attention. In the early days, alloy materials were used, and later carbon fiber wear-resistant plastic materials were used. More advanced nozzles use ceramic materials and diamonds to make them more durable.

With the miniaturization of the components and the reduction of the clearance with the surrounding components, the structure of the suction nozzle has also been adjusted accordingly Make a hole in the suction nozzle to ensure that small parts such as 0603 are balanced when picking up. Pick up and place them without affecting the surrounding components for installation

(2) Visual calibration system. With the increasing demand for small, light, thin and high reliability of electronic products, the reliability of surface mounting can only be ensured by precisely placing the fine pitch components. In order to accurately install thin pitch components, the following factors should generally be considered.

1. PCB positioning error. Generally, PCB circuit patterns do not always correspond to machined holes and PCB edges mechanically located on the PCB, which will result in installation errors. In addition, the circuit pattern on the PCB is deformed, the PCB is deformed and warped, and other defects will lead to installation errors.

2. Part alignment error. The center line of the component itself does not always correspond to the center line of all wires. In addition, when the placement system uses a mechanical centering claw to center the component, it may not be possible to ensure that the center lines of all wires of the component are aligned. In addition, in the packaging container, or when the centering claw is clamped and centered, the component leads may have defects such as bending, twisting and overlapping, that is, the leads lose coplanarity. These problems will lead to placement errors and reduce placement reliability. When the component lead deviates from the pad by no more than 25% of the lead width, the surface mounting is successful. When the lead spacing is narrow, the allowable deviation is small.

3. Motion error of the machine itself Mechanical factors affecting placement accuracy include: X-Y axis movement accuracy of placement head or PCB positioning table, part centering mechanism accuracy and placement accuracy The vision system has become an important part of high precision placement machine

The machine vision system consists of two parts: vision hardware and vision software. The CAMera is the image sensing component of the vision system, usually using a solid-state camera. The main component of the solid-state camera is the integrated circuit. A CCD array composed of many small precision photosensitive elements is fabricated on the integrated circuit chip. The electrical signal output by each photosensitive detection element is proportional to the intensity of the light EMItted from the corresponding position on the observation target, and the electrical signal is recorded as the gray value of the point. Point coordinates determine the position of a point in the image. The analog electric signal generated by each point is converted into a value between 0 and 255 through analog/digital conversion, and then transmitted to the computer. A large amount of information collected by the camera is processed by a microcomputer, and the processing results are displayed on the monitor. The camera is connected with the microprocessor, the microprocessor, the actuator and the display through the communication cable.

The main factors that affect the accuracy of vision system are the number of camera elements and optical magnification. The more camera points, the higher the accuracy; The greater the optical magnification of the image, the higher the accuracy. Because the greater the optical magnification of the image, the more image elements corresponding to a given area, and the higher the accuracy. However, when zooming in, it is more difficult to find the corresponding figure. This accuracy reduces the placement rate of the placement system. Therefore, the appropriate optical magnification of the camera must be determined according to the actual needs.