SMT chip structure principle and operation process

SMT mounter is the production equipment with the highest technICal content on SMT production line It is responsible for accurately and undamaged placement of components on the PCB at the designated location of the equipment There are many technologies that can measure the function of the mounter The most important are placement speed, installation accuracy, PCB standard, installation proportion, etc In the whole SMT production line, users usually pay attention to the placement machine, whose function is to determine the main standards of the production line

With the continuous development of SMT chip technology, there are now many SMT mounters used in various applications and environments, such as multi-function mounters, SMAll mounters, high-speed mounters, LED dedicated mounters, and more non customized mounters.

Basic introduction to the placement machine: In the placement machine production line, the placement machine is the most important equipment. Its science and technology have developed rapidly. From the early low-speed mounters to the current optical mounters, it has multiple functions and flexible connections., It can fully meet all SMT Production requirements.

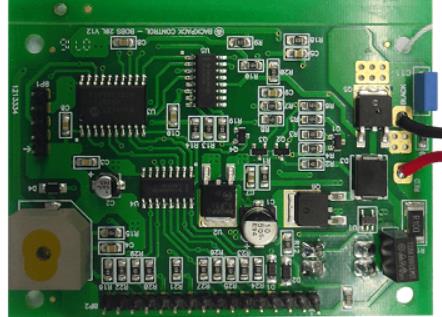

Circuit board

Overview of SMT placement machine 1: SMT placement machine is a machine that pastes a single electronic placement component onto a PCB board Generally, it can be divided into high-speed machines and general-purpose machines The machine will be fitted with relatively large components It is mainly controlled by PT or other computers, which means it is SIMilar to remote control. All operations of the machine are controlled by computers

Overview of SMT machine 2: SMT machine: also known as "SMT equipment", "SMT machine", "SMT system" (SMT system). On the production line, it is equipped on the dispensing machine or screen printing machine. After that, it is a device that accurately places SMT components on PCB pads by moving the tip. It is divided into manual and automatic.

The structure and principle of the placement machine are analyzed comprehensively. The automatic placement machine is a device used to realize high-speed, high-precision and full-automatic placement. It is the most critical and complex equipment in the whole SMT production. The mounting machine is the main equipment of the mounting production line. The placement machine has developed from the early low-speed mechanical placement machine to the high-speed optical centering placement machine, and has developed into multi-functional, flexible connection and modularization.

What is the operation process of SMT mounter?

SMT mounters are mainly used in LED lamps, electronic products and display screens. It has the characteristics of intelligent placement, more accurate identification and positioning, and more durable. It can quickly and accurately install SMC/SMD components to the designated pad position on PCB without damaging components and PCB by absorbing displacement, positioning and placing functions.

1. Preparation before SMT mounter

1. Prepare relevant product process files.

2. According to the installation schedule of product process files, select data (PCB, components) and check them.

3. For the PCB that has been opened, clean and bake it according to the length of the opening time, whether it is wet or contaminated.

4. Check the components and parts after opening, and handle the wet components and parts according to the SMT process component management requirements.

5. Select the leaking feeder according to the specification and type of the component, and correctly install the component tape feeder. When loading -. The center of the part must be aligned with the pick center of the feeder.

6. Equipment status check:

a. Check that the air pressure of the air compressor meets the equipment requirements, generally 6kgjf/cm2 ~ 7kgf/cm2.

b. Check that there are no obstacles around the guide rail, the moving range of the placement head, the automatic replacement nozzle magazine and the tray rack.

Startup process of chip mounter

1. Start the machine according to the Equipment Safety Technical Operating Procedures.

2. Check whether the air pressure of the mounter meets the equipment requirements, generally about 5kg/crri2.

3. Turn on the servo.

4. Return all the axes of the mounter to the source point.

5. Adjust the width of the FT1000A36 guide rail of the mounter according to the width of the PCB. The width of the guide rail should be about 1mm greater than the width of the PCB, and ensure that the PCB slides freely on the guide rail.

6. Set and install PCB positioning device:

1. First, set the PCB positioning method according to the operation rules. Generally speaking, there are two methods of pin positioning and edge positioning.

2. When using pin positioning, install and adjust the position of the positioning pin according to the position of the PCB positioning hole L. Make the positioning pin just in the middle of the PCB positioning hole, so that the PCB can move up and down freely.

3. If edge positioning is used, the position of stop and top block must be adjusted according to the overall dimensions of PCB.

7. Place PCB bracket and use bushing according to PCB thickness and external dimensions to ensure uniform force on PCB and no looseness during patch If the PCB is mounted on both sides, after the B (first) side is mounted, the PCB bracket thimble must be re adjusted to ensure that when the A (second) side is mounted, the PCB bracket sleeve should avoid the installed B side Installed components

8. After setting, PCB can be installed for online programming or patch operation.