Structural characteristICs of PCBA test

PCBA board shall be tested in advance before use It can only be used after passing the test If they do not pass the test, they cannot be used However, many problems need to be considered when testing PCBA boards First of all, you should know the basic content of PCBA board testing

1. The aging test is mainly to make PCB board and electronic products power on for a long time, keep them working, and observe whether there is any fault. After aging test, electronic products can be sold in batches.

PCBA board is often heated, resulting in greater temperature difference than PCBA board. Once the temperature difference exceeds the standard, it will lead to poor welding, and the temperature difference must be controlLED during the operation. The thermal design of PCBA board consists of many parts, each of which has different characteristics.

If the temperature difference is large, it will also lead to poor welding, such as QFP pin opening, rope suction, chip element column, BGA solder joint displacement, shrinkage and fracture. We can solve some problems by changing the heat capacity.

(1) Thermal design of radiator pads. In the welding of radiator elements, there is less tin in the radiator pad, which is a typical application that can be improved through radiator design.

PCB can be designed by adding the heat capacity of cooling holes. If the ground plane is less than 6 layers, connect the cooling hole to the internal ground plane. Part of the cooling layer can be isolated from the signal layer, and the aperture can be reduced to the minimum available aperture.

(2) Thermal design of high-power grounding socket. In some special product designs, sockets sometimes need to be connected with multiple ground/leveling layers. Because the contact time between the pin and the tin wave during peak soldering is very short, usually 2~3 s. If the heat capacity of the socket is large, the lead temperature may not meet the welding requirements, forming cold solder joints.

In order to avoid this situation, a crescent design is used to separate the welding hole of the chip factory from the electric layer by passing large current through the power hole.

(3) In the thermal design of BGA solder joints, due to the unidirectional solidification of solder joints in the mixing process, a special "shrinkage fracture" phenomenon will occur. The root cause of this defect is the characteristics of the mixing process itself, but it can be improved by optimizing the BGA corner routing to slow its cooling.

According to the experience provided by the case, the weld with shrinkage fracture is usually located at the corner of BGA. By increasing the heat capacity of the BGA fillet weld or reducing the heat conduction velocity, they can be cooled synchronously or subsequently with other welds to avoid the phenomenon that the weld falls off due to cooling first under the BGA warping stress.

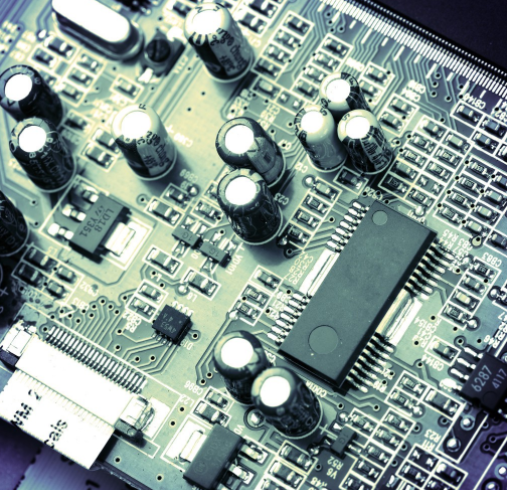

pcba board

2. ICT test mainly includes circuit on-off, voltage and current value and fluctuation curve, amplitude, noise, etc.

3. The FCT test needs to burn the IC program, compare the functions of the entire PCBA board, find hardware and software problems, and provide necessary production tools and test benches.

4. The fatigue test is mainly to take PCBA boards from PCBA factory for high-frequency and long-term functional operation, observe whether there is a failure, judge the failure probability in the test, and echo the working efficiency of PCBA boards in electronic products.

5. The PCBA board is mainly exposed to extreme temperature, humidity, dripping, splashing and vibration in harsh environment to obtain the test results of random samples, so as to infer the overall reliability of PCBA board batch products