TechnICal knowLEDge of electronic component installation

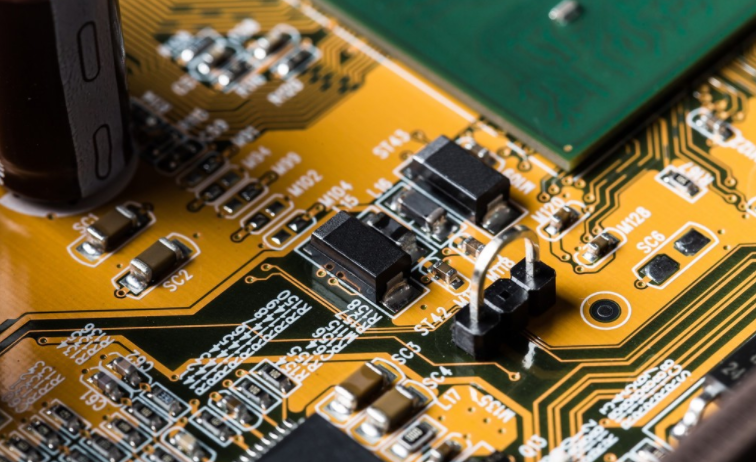

The insiders know that the SMT electronic component board manufacturer of PCBA is the basis of electronic products ElectronIC components are the general term for electronic components and electronic equipment Common electronic components of SMT include resistors, capacitors, resistors, capacitors, inductors, diodes, triodes, integrated circuit pins and fuses

Common identification methods for polar components with surface roughness of printed circuit board manufacturers are as follows:

Special attention should be paid to the polar components during the whole processing of PCBA, because the wrong directional components will lead to batch accidents and the failure of the whole PCBA board. In this regard, it is very important for the technical engineers and production personnel of surface roughness to understand the polar components of surface roughness.

1. Definition of polarity

Polarity means that the positive and negative poles or the first pin of the component are in the same direction as the positive and negative poles or the first pin on the PCB. If the direction of the component does not match the direction on the PCB, it is called a reverse defect.

2. Polarity identification method: chip resistor has no polarity, capacitor and ceramic capacitor have no polarity, and tantalum capacitor has polarity; PCB plate and positive pole MARK of equipment: 1) color band mark; 2) "+" sign; 3) Bevel mark. Aluminum electrolytic capacitor has polarity, and part marks: color band represents negative pole; PCB plate mark: color band or "+" indicates positive pole.

3. Inductor: There is no polarity requirement for package at both ends of wafer coil and other welding, and there is polarity requirement for multi pin inductors; Part mark: point/1. indicates polarity point; PCB plate mark: point/circle/"*" indicates polar point.

Components

4. LED: chip surface mounted LED polarity, negative pole mark of components: green is negative pole; Negative pole mark on PCB: 1) vertical strip, 2) color band, 3) silk screen acute angle; 4) Silk screen ” Box represents.

5. Diode: surface roughness surface mounting diode, polarity at both ends. Negative pole mark of parts: 1) color band, 2) groove, 3) color mark (glass body); Negative pole mark of PCB: 1) vertical strip mark, 2) color band mark, 3) silk screen acute angle mark, 4) "| ” Box marking.

6. Integrated circuit: The soil type package has polarity. Polarity instructions: 1) ribbon, 2) symbol, 3) concave point, groove, 4) bevel; The standard operating procedure or quality assurance plan type package has polarity. Polarity instruction: 1) concave point/groove instruction, 2) one point is different from the other two/3. points (size/shape); The BP type package has polarity. Polarity instruction: 1) One point is different from the other two points (size/shape), 2) Bevel instruction, 3) Symbol instruction (leveling bar/"+" symbol/point).

7. Ball grid array: part polarity: concave/groove mark/dot/circle mark; Polarity of PCB board: it is indicated by circle/dot/letter "1 or a"/bevel. The polarity point of the part corresponds to the polarity point on PCB.

Identification method of surface roughness resistance: the color of color ring resistance generally includes 12 colors: brown, red, orange, yellow, green, blue, purple, gray, white, black, gold and silver. The top ten colors represent 1 to 9 (black represents 0), and gold and silver represent two kinds of errors (plus or minus 5% and plus or minus 10%)

Normally, there are four polychlorinated biphenyl plants on the element resistance The first two colors represent pure digits For example, orange black represents the number 30 (not 30 °), and the third color ring represents the number of 0 For example, if the RBT is red on the 3rd day, there are two zeros behind the digit 30, and the resistance value of this resistance is 300 Ω (3K Ω); The color of the last colored ring is gold or silver. For example, if the last color ring is silver, what it represents here is that the resistance value of the resistance hovers between plus or minus 10% of 3000 Ω (the actual resistance value of the resistance is any determined value within this range).

Polarity judgment and capacity identification of capacitors in SMD processing: capacitors are mainly divided into electrolytic capacitors and chip capacitors. The shape of the electrolytic capacitor is cylindrical, and its cylindrical surface is marked with capacitance and polarity (the long leg is the positive pole, and the short leg is the negative pole).

There is no polarity difference in the battery PCB board PCB chip processing plant surface roughness component capacitance in the process workshop Its shape is usually pie shaped Components are marked with 3 digits, of which the first, second and third digits represent capacitance values, and the third digit represents 0 digits For example, 233 represents the capacitance value of 23000pf, i. e. 0.023 micro method