Differences between PCBA one-stop servICe contractors and non contractors

PCB manufacturersare in the 21st century Many new electronic products and technologies will be updated rapidly As the most important core component of electronic products, PCB processing industry has been highly valued by major enterprises in the industry Quality, delivery time and cost PCBs processing industry will directly affect the quality, delivery time and cost of the entire product delivery

At present, the world famous polychlorinated biphenyl agent companies are all well-known enterprises such as Foxconn, Weifang, BYD, etc. They have been cooperating with many international well-known electronic product developers. Their successful cases lead to the processing methods of modern electronic manufacturing services, which can be summarized into two main types: incoming material processing and contracting data. At present, more and more enterprises in major industries choose PCB packaging mode. Why do more and more enterprises choose PCB contract information? What problems will these two models encounter in real life? The following is a brief discussion and analysis of PCB.

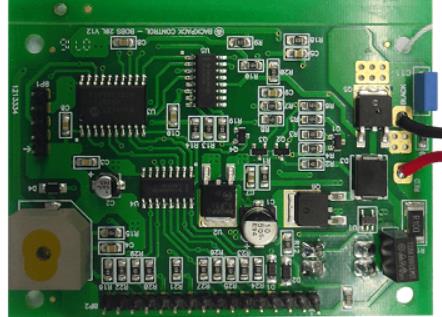

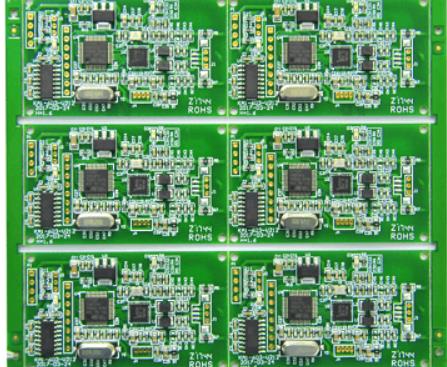

Polychlorinated biphenyls

1. Concept description

1). Polychlorinated biphenyl package is actually a treatment method, including searching all processing processes of PCB production, raw material procurement, SMT processing, polychlorinated biphenyl testing, product assembly, etc PCBs are treated inside To put it SIMply, the buyer places an order with the supplier, and then the supplier delivers the finished PCBs to the customer. All the intermediate processes are completed by the supplier

2). The difference between PCBs packaging and PCBs packaging is that all information on the BOM is provided by the buyer, and the supplier is only responsible for production, which is equivalent to processing from incoming materials.

2. Brief analysis of two methods

1) The polychlorinated biphenyl contractor does not include data. The advantages are: the quality and brand of each data are relatively controllable; Disadvantages: facing a large number of parts suppliers, it is not easy to control them as a whole, and procurement corruption is easy to occur, requiring more personnel. The threat is that once a large number of suppliers have supplier supply problems, a whole set of supply problems will be involved.

2) The advantages of PCB contractor data are: integrated supply chain access, better bargaining power, reduced number of suppliers, avoided the passive situation of PCB manufacturers looking everywhere, and saved a lot of other processing time, for example; Signing contract terms, order follow-up, process payment, ERP operation, etc. Disadvantages: there may be problems in raw material quality and raw material brand control; Threats are: timely payment may lead to overall data supply problems; However, PCB contractor information also has the opportunity to reduce labor costs by investing fewer people in disguised financing (account negotiation). Large PCB suppliers have greater bargaining power over raw materials and can reduce costs at the same time.

3. Current mainstream pipeline

It is always difficult for enterprises to choose the two PABA treatment modes of PCB contractual treatment and incoming material treatment, and everything has two sides.

Combined with comprehensive analysis and evaluation, PCBs contractor package can save customers time, cycle, inventory and other cost issues. The electronic processing mode of PCB contractor package can liberate enterprises from the electronic manufacturing link and avoid investment in electronic material procurement, storage, ex warehouse, logistics and personnel. At present, this method is becoming the first choice for system integrators and product manufacturers.

However, considering the confidentiality of some core integrated chips and some burning programs used for production, the more mainstream pipeline is to use partial packaging methods, that is, the core chips are provided by enterprises, and other PCB and blocking container parts are provided by polychlorinated biphenyl processing plants. At the same time, the simple test and burning are completed by the polychlorinated biphenyl processing plant, and the core program burning and testing are completed in the enterprise factory.

4. Potential derivative risks PCBs Contracted Packages

It is very important to review suppliers in the service package of PCB contractors, which almost determines the key to successful cooperation and whether the cost and product turnover can reach the expected goals. It is undeniable that the MARKet is also full of enterprises that earn excess profits by sacrificing customer quality and stealing raw materials, but after all, this is unsustainable. In this regard, the selection of PCBs contractor information suppliers should be included in the scope of strategic cooperation with suppliers. Of course, the procurement corruption of such key suppliers in the import process also needs the attention of enterprises.