PCB manufacturers explain the development trend of soft board materials

Circuit board manufacturers, circuit board designers and PCBA manufacturers explain the development trend of soft board materi

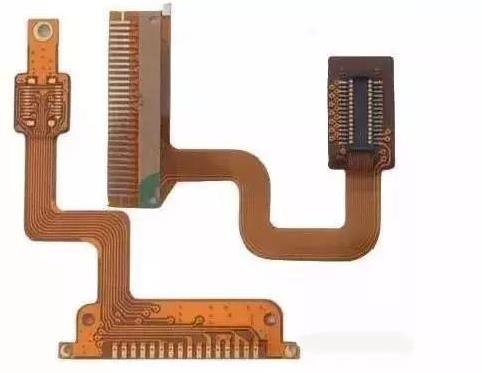

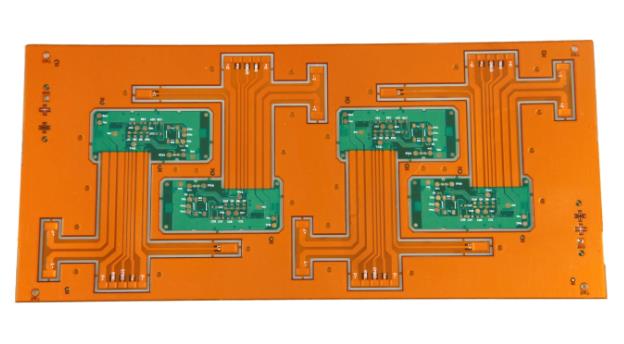

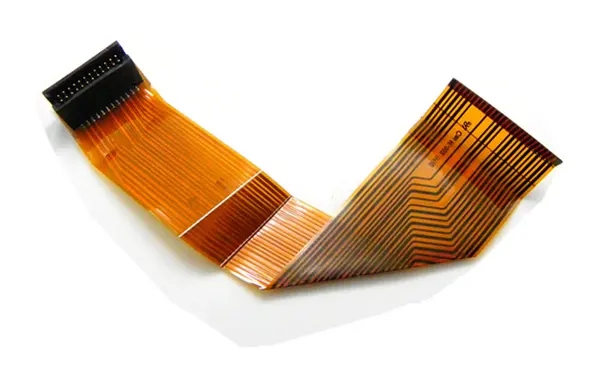

The domestIC soft board material industry has gone from being completely dependent on imports 20 years ago to being the world's second largest supplier. During this period, the soft board industry has undergone restructuring and growth and decline. However, its characteristics are consistent with the light weight and thin type required by application products. In addition, the increasingly strong demand of electronic products for information and communication mobility has prompted the soft board MARKet to show a positive upward trend. In recent years, The composite growth rate of the overall soft plate market is up to more than 40%, which makes the demand of the upstream soft plate material industry increase along with it. However, the over investment effect caused by the market boom also makes the soft plate and soft plate material industry face the fate of the traditional industry of price cutting competition and declining profits. How to win in the competition will be an important topic for the future industry.

The advantage of China's softboard industry lies in its strong application industries, such as monitors, mobile phones and notebook computers, which will be an important source of support for the growth of softboard. In addition, the successful application of the strategy of operating the localization of upstream substrate plates for many years, and the evolution of the soft plate manufacturing process driven by the self-made substrate materials required for medium and low level products, have made the overall supply chain of the domestic soft plate industry to a certain extent. The industrial disadvantage is that after the profit of middle and low level products has increased greatly, a large number of successors have invested. The price cutting competition has reduced the overall soft board profit, and at the same time, it has affected the regular development of China's soft board industry. Moreover, because the advanced upstream substrate material (soft carrier plate) and process technology cannot be broken through, the application of high-order products with the highest profit, such as COF driven IC structure carrier plate material, is still completely subject to Japan. Because of manufacturing costs, local supply and other factors, the United States and Japan have transferred some low-end products to Southeast Asia and Chinese Mainland. Taiwan has received most of the transfer orders due to its demand for process technology and local terminal products. This phenomenon will have good advantages and opportunities for the development of the softboard industry due to the support of China's mobile phone and display industries. Don't forget South Korea, which has a strong system, because the system industry has the right to choose key materials and assemblies. In the past, South Korea was one of the important countries for FPC export in China because its technology in the circuit manufacturing process and substrate material industry lagged behind China. However, recently, due to the growing strength of its large domestic factories, its investment and effectiveness in soft board materials and manufacturing technology will gradually take shape, This will pose a huge threat to China's soft board industry, which lacks strong system industry support. In addition, the rise of the emerging mainland has attracted a large number of FPC manufacturers from Japan, the United States, Taiwan and South Korea to invest and settle in this year. Driven by the clustering effect, production bases have been established in eastern and southern China. Will this division drive the rise of the mainland's local soft board industry? It deserves our attention.

China's long-term development strategy in the soft board industry should combine the upstream base plate materials with the manufacturing process and application technology, take the development of self owned materials and technologies with related manufacturing process technologies as the main axis, and take the existing strong asset communication and optoelectronic application industries as the carrier to build a complete industrial system. It is necessary to master the proactive research and development strategy of upstream key materials and components. In the aspect of substrate materials, the short term will be started by high-class high-density substrates to strengthen the already basic medium and low level industrial chain. In the future, the medium and long term should take environmental protection and green issues into consideration, with recyclable substrate as the development focus of the next generation substrate material industry. At the same time, the function of the substrate will be integrated and designed to conform to the future industrial application trend. As for the substrate process, the thin Copper substrate process of high-density thin lines must be followed, And the development of additive or sEMI additive methods. At the same time, considering the development of new generation of substrate materials, the research and development of new substrate processing technology must also be planned SIMultaneously.

We hope to find out the demand of product orientation, and then lead to the evolution of soft board manufacturing technology, with the focus on the development of soft board material technology, taking into account the domestic situation of soft board industry and referring to the advanced technology trend of soft board industry. In this paper, the future trend and development of soft plate materials will be briefly described under the topics of new soft plate substrate, ultra-thin soft plate substrate, photosensitive protective film, additive soft plate materials, soft plate and soft electronics. als to youPCB manufacturers, PCB designers and PCBA manufacturers will explain the development trend of soft board materials to you.