3D printing alloy! Soft robot and flexible circuit board are softer

PCB manufacturers, PCB designers and PCBA processors will explain the new breakthrough of 3D printing alloy! Soft robot and Flexible circuit board are softer

We must have seen many soft robots in the circuit board factory. Like industrial robots, they only use soft materials to drive the gripper, while the parts that control and carry the gripper are hard metal and circuit boards.

They are either like Harvard's flexible octopus. They are soft and do not need electrIC drive. The appearance of this robot is a sensation, because it brings a new definition to the soft robot.

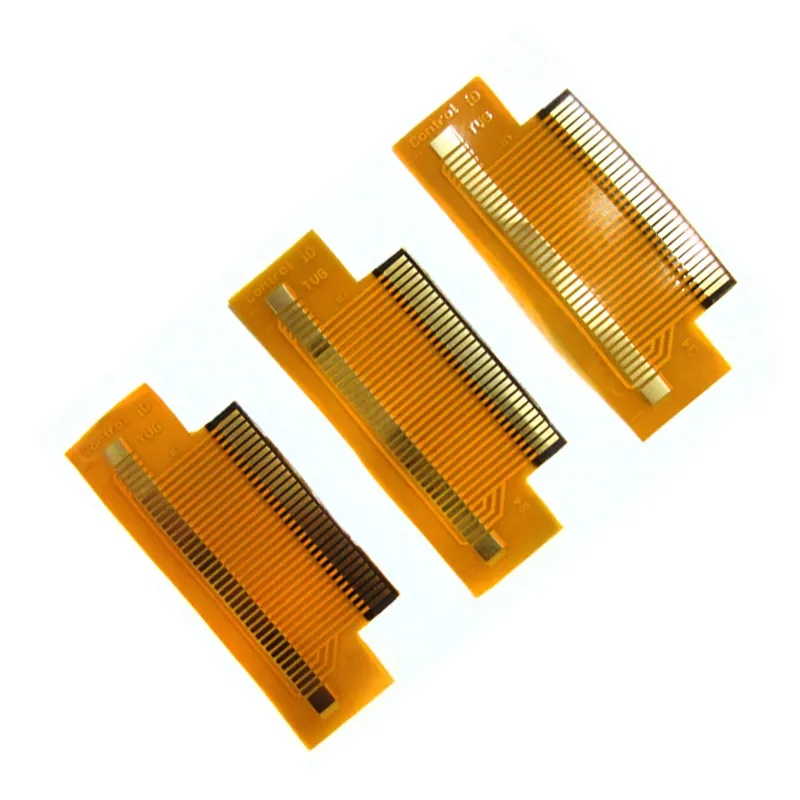

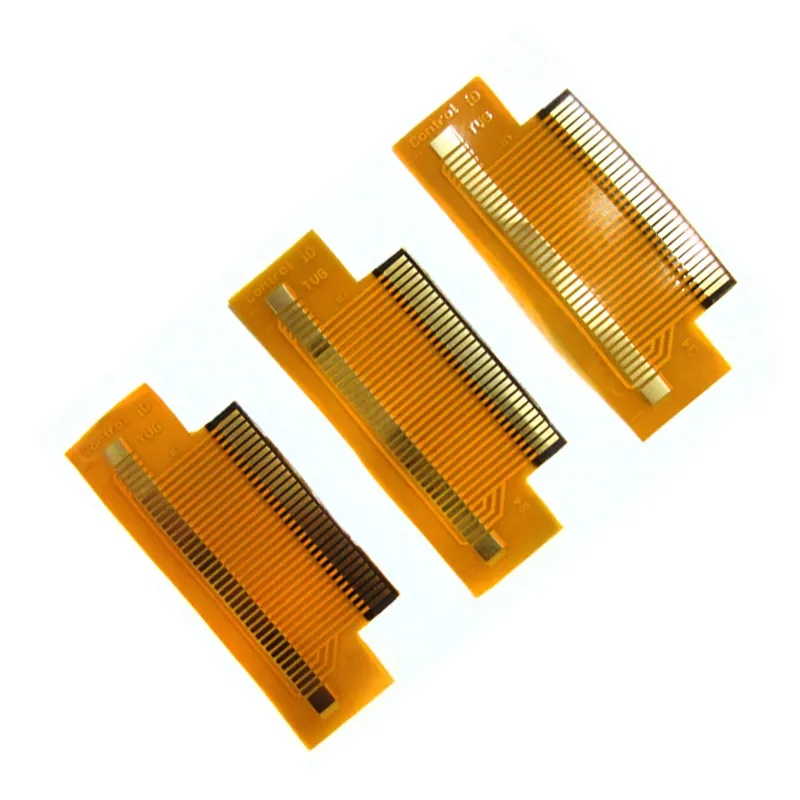

A while ago, with the exposure of the flexible screen production line, the flexible screen has also become a big fire. The display screens that can fly in the wind and shine brightly can not help but make many of us imagine the computers that can be rolLED up or the mobile phones that can be worn in the hands that appeared in science fiction movies.

However, we have to admit that the reality tends to develop more slowly than people imagine. One of the real conditions that restricts the development of flexible mobile phones or software robots in the "softer" direction is that their circuits are still difficult to be completely flexible.

At present, however, there seems to be a new solution for flexible circuits. The research team of the Institute of Robotics and Intelligent Systems in the School of Engineering of Oregon State University has developed a metal alloy that can be printed in 3D using a new method, and published its paper in the journal of advanced material technology.

They used ultrasound to put nickel nanoparticles into the liquid metal alloy Galinstan, thus changing the physical state of the alloy, making it appear a viscous paste state. This pasty metal alloy can not only maintain its fluidity and softness, but also, more importantly, break the disadvantage that liquid alloy cannot complete 3D high-level printing. The printed two layers of circuits do not touch each other but weave each other.

The researchers of the team said that gallium alloys have low toxicity, good conductivity, low price and "self repair", which means they can re attach at the breakpoint. Therefore, gallium alloys have been widely used as conductive materials in flexible Electronic devices. But before that, the use of gallium alloy was limited to 2D printing. The current 3D printing gallium alloy technology can completely change the application mode of liquid metal in manufacturing flexible technology.

Therefore, this paste alloy can print many shapes that were previously considered impossible through 3D printing technology. It can also collapse instantly under the gentle pressure of people.

The characteristics of this metal alloy result in its availability in flexible circuits. When external force is used to make a breakpoint for the circuit, we can also make the circuit return to normal energization by squeezing.

Moreover, even if the two flexible circuits are completely broken, the circuit can be energized only through butt joint. However, this technology is still in the research and development stage in the laboratory, and there is still a long way to go before it can be truly applied to reality. So let's wait and see what the future holds. PCB manufacturers, PCB designers and PCBA processors will explain the new breakthrough of 3D printing alloy! Soft robots and flexible circuit boards are more flexible.