Raw materials in the circuit board industry rose, and cost control was not optimistIC

PCB manufacturers, PCB designers and PCBA processors explain that raw materials in PCB industry are rising, and cost control is not optimistic

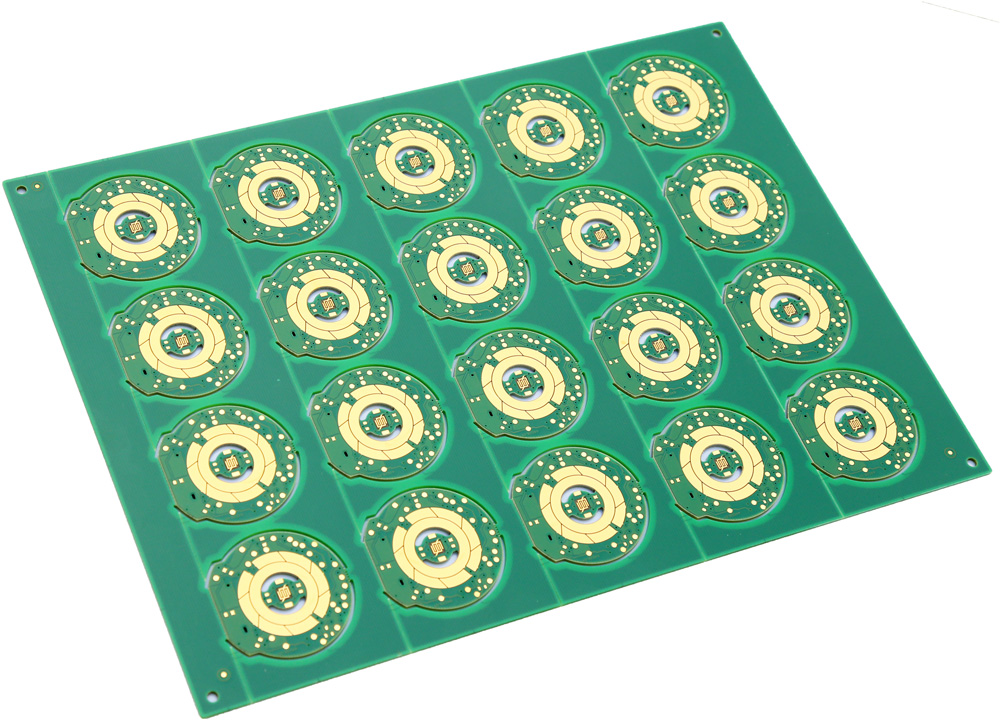

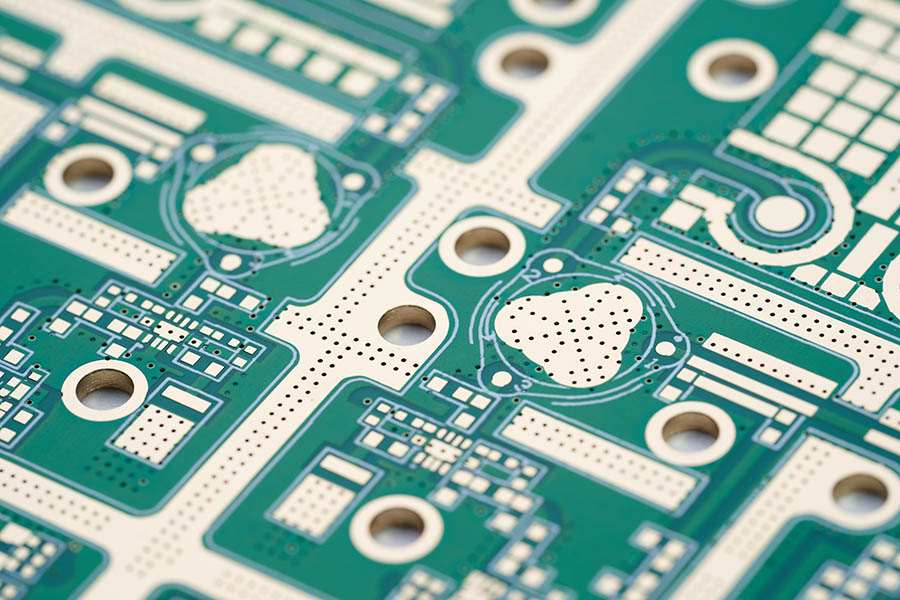

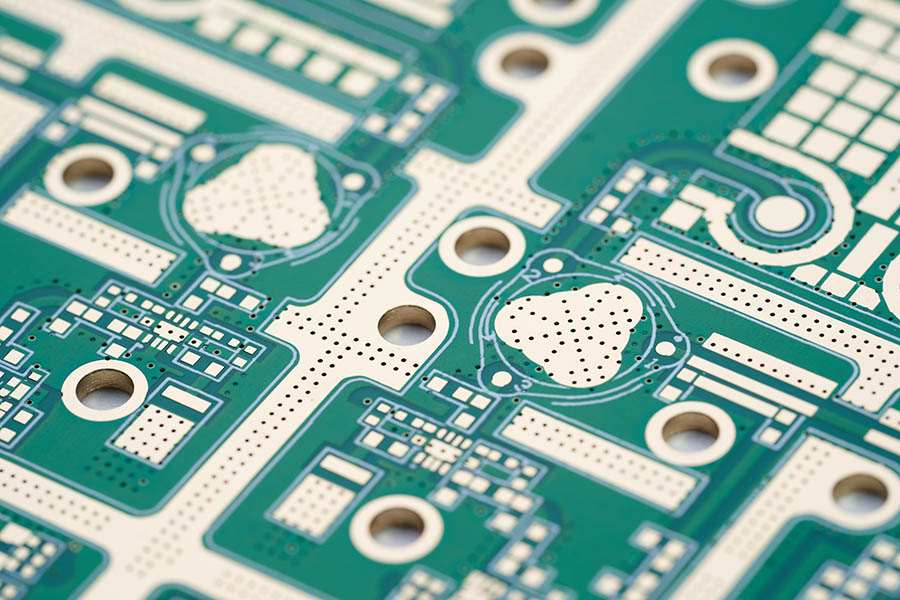

The circuit board (printed circuit board) is an important electronic component. Its main function is to connect electronIC components. Downstream demand mainly includes: communication, automobile, and consumer electronics.

Since this year, the gross profit of products in the first half of the year has declined due to the rise of the cost side of PCB. In the third quarter, the price rise of raw materials was controlLED, and the gross profit margin of PCB was increased, but the impact was very limited. In the long run, cost control was difficult to continue.

Since this year, the price of the upstream industrial chain of circuit boards has continued to rise all year round. Specifically, copper clad laminate (CCL) is the largest cost source of circuit boards, accounting for 30% and 40% of the total labor cost. Therefore, the price of CCL will greatly affect the production cost of circuit boards. CCL will raise its price by 30% in the first quarter of this year and by 20% in the second quarter. The growth of thick boards has exceeded 100%, and that of thin boards has also increased by 30% - 50%. As a result, the production cost of PCB in the first half of the year was greatly increased, and the price increase of CCL was also caused by the price increase of raw materials. Since September, CCL has shown a price rise letter again, and the expectation of the future cost price of PCB is still not optimistic.

Specifically:

Among the raw materials of CCL, copper foil accounts for 43% of the cost, resin accounts for 26%, and glass fiber cloth accounts for 20%. The price increase in the first half of the year was very obvious, mainly because of the large demand in the downstream and the tight capacity. The rapid development of the downstream industry chain mainly includes automobile, wind power, etc.

For example, the raw materials of circuit boards and lithium batteries both need electrolytic copper foil. This year, the demand for lithium batteries comes from new energy vehicles and the release of energy storage, resulting in a very tight production capacity. Therefore, the price of copper foil has been rising all the way.

The downstream demand of resin is relatively extensive, and it permeates into daily life, high-tech and other fields. The price rise trend continued throughout the year. On the other hand, it was also because the power limitation had a great impact on the capacity. The price was originally high, but after the production limitation, there was no goods available, and the price continued to rise.

On the one hand, the production capacity of fiberglass cloth is limited, on the other hand, it is also a large demand. The product is used as the main raw material for the lightweight of new energy vehicles. Therefore, the price in the first half of this year has also risen all the way. The release of new capacity is concentrated in the second half of this year. Since July, the price rise has slowed down.

To sum up, although the prices of copper foil and glass fiber cloth have been under control since the third quarter, and the prices of resin have continued to rise, it is difficult to control the cost of circuit boards because the large-scale demand is much faster than the supply, which will have a certain impact on the gross profit margin in the future. PCB manufacturers, PCB designers and PCBA processors explain that raw materials in PCB industry are rising and cost control is not optimistic.