Battery FPC raw materials have large space, and PTFE is expected to become potential

Circuit board manufacturers, circuit board designers and PCBA processors will explain to you that there is a large space for battery FPC raw materials, and PTFE is expected to become the trend of substrate

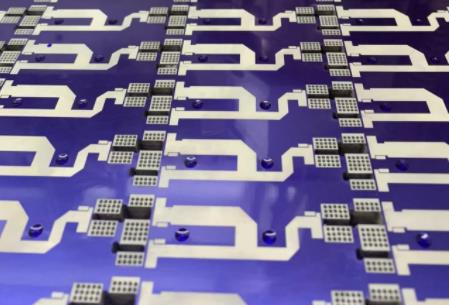

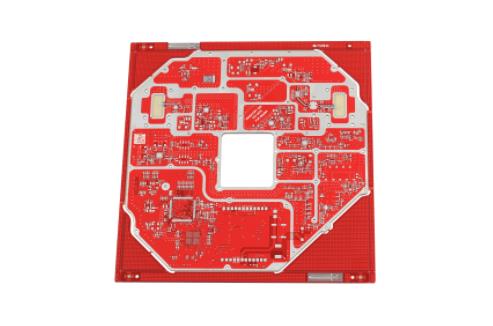

Flexible Printed Circuit Board (FPC) is referred to as "flexible board", commonly known as FPC in the industry. It is a flexible insulating substrate (mainly polyimide or polyester film) The printed circuit board has many advantages that the hard printed circuit board does not have. For example, it can bend, wind and fold freely. The volume of electronIC products can be greatly reduced by using FPC, which is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerOSPace, military, mobile communications, laptops, computer peripherals, PDAs, digital CAMeras and other fields or products.

FPC also has the advantages of good heat dissipation and weldability, easy assembly and connection, and low comprehensive cost.

flexible printed circuit board can be divided into single-sided, double-sided and multilayer boards. The substrate used is mainly polyimide copper clad laminate. This kind of material has high heat resistance and good dimensional stability. It is pressed with the covering film with both mechanical protection and good electrical insulation properties to form the final product. The surface and inner conductors of double-sided and multilayer printed circuit boards are metallized to realize the electrical connection of the inner and outer circuits.

The battery FPC industry chain includes upstream raw material suppliers: copper foil substrate CCL, covering film CVL, reinforcing sheet, adhesive, electromagnetic shielding film, as well as copper ball, sEMI curing sheet, gold salt, ink, dry film, etc; There are also SMT process suppliers, laser drilling machines, electroplating machines, exposure machines and other equipment suppliers (the ability of SMT to print parts has a great impact on the profitability of manufacturers), FPC manufacturers in the middle reaches, and electronic product module parts manufacturers and terminal electronic product manufacturers in the downstream. For details, see:

FCCL: It is the key substrate for the production of battery FPC, with the cost accounting for 40% - 50%. It is made of flexible insulation layer and metal foil (copper foil). According to the product structure, Flexible copper clad laminate can be divided into two categories: three layers of flexible copper clad laminate (3L-FCCL) with adhesive type and two layers of flexible copper clad laminate (2L-FCCL) without adhesive type; According to the product thickness, each type of flexible copper clad laminate is divided into ordinary type and ultra-thin type. In terms of production capacity, Japan and South Korea are the main production places. In 2018, the manufacturing capacity of Japan, South Korea and Chinese Mainland accounted for 36%/22%/21% respectively, and the capacity of Chinese Mainland ranked third. At present, domestic FCCL products are mainly concentrated in the low and middle end, and high-end products such as adhesive free flexible copper clad laminate are scarce in China.

Copper foil: it is divided into electrolytic copper foil and calendered copper foil, with thickness of 1OZ, 1/2OZ, 1/3OZ and 1/4OZ.

Covering film: It is composed of release paper, adhesive, and PI. Finally, only adhesive, and PI are retained on the product.

Reinforcement: It is a specific material for FPC, which is used in a specific part of the product to increase the support strength

Electromagnetic shielding film: it is the core material for FPC of battery to suppress electromagnetic interference. At present, electromagnetic shielding film mainly has three structures, namely conductive adhesive type, metal alloy type and micro needle type

Teflon PTFE for soft board trend is used for 5G high frequency and 6G specifications. In September 20, Sumitomo Electric Co., Ltd. of Japan developed a flexible printed circuit board (FPC) "FLUOROCUIT" made of fluororesin with low transmission loss in millimeter wave band and excellent flexibility, and successfully mass produced it. Fluorine resin has low dielectric constant and dielectric loss tangent. Compared with liquid crystal polymer (LCP), which is increasingly used in high-frequency substrate, the transmission loss can be further reduced. For example, the transmission loss in the 40 GHz band is about 40%. PCB manufacturers, PCB designers and PCBA processors will explain that there is a large space for battery FPC raw materials, and PTFE is expected to become the trend of substrate.