The raw materials required for the production of PCB products in each PCB industry have their own scope and characteristICs. For PCB industry, copper clad laminate, copper foil and fiber (P sheet), which are used for lamination, can be calLED main materials, while ink, dry film and liquid medicine are essential auxiliary materials. As the first step of material coding, materials must be classified and coded first. There are many methods and bases for distinguishing material types and codes, but the overall difference is not too big.

Copper clad laminate (CB), copper foil (CF), fiber (PP), ink (IN), dry film (DF), liquid medicine (MT), drill bit (DR), maintenance supplies (MA), consumables (OT), finished products.

Based on the experience of implementing ERP system in many PCB enterprises, the following author analyzes the detailed coding rules of various material types, and analyzes their advantages and disadvantages, hoping to enlighten the industry.

Analysis of ccl coding rules

As the most important material in PCB industry, the coding rules of copper clad plate generally need to consider such factors as copper plate model, copper plate property, copper plate waterMARK, copper plate thickness, copper surface thickness, copper plate size, and plate color. Therefore, the coding of copper clad plate will be the most complex and difficult matter for material coding in PCB industry.

1. Rules: copper plate model+nature+with or without watermark+copper plate thickness+copper surface thickness+size+plate color

2. Rule analysis: This rule code has 14 digits in total, which can completely reflect the material properties and characteristics, and provides good expansion space.

Some people like to mark the supplier number in the CCL code, but the author thinks it is unnecessary to do so: because this will artificially increase the number of codes, and the copper plate model itself also reflects the supplier's information, such as S1141 for profit material, KB6160 for Jiantao material, etc.

As for the size of the copper plate, some companies prefer to use the length and width of the copper plate as the code directly. For example, the 41 "* 49" copper plate is coded 410490. Although the code length has increased by three bits, it makes the code more intuitive, which is a correct choice.

Analysis of copper foil coding rules

Generally speaking, for copper foil coding, factors such as copper foil thickness, copper foil width and supplier number need to be considered.

1. Rules: copper foil thickness+copper foil width+supplier number

2. Rule Analysis: This rule code is about 11 digits in total, which completely reflects the basic properties of the material. In terms of scalability, such as the thickness and width of copper foil, additional codes can be flexibly added as required.

Analysis of fiber coding rules

In general, for fiber (P sheet) coding, factors such as fiber thickness, copper foil width and size should be considered.

1. Rules: fiber model+fiber specification+size

2. Rule analysis: this rule code has 10 digits in total. Some companies like to add supplier codes to their codes. The author believes that the supplier can be clearly recognized from the fiber model, so it is not necessary to re identify it in the material code.

Analysis of Ink Coding Rules

Generally speaking, the model, color and process used shall be considered for the coding of ink. It is also special for PCB industry to distinguish the use of ink according to the process.

1. Rules: ink model+ink color+process used

Analysis of dry film coding rules

Generally speaking, the model, size and length of dry film shall be considered for coding. The length here refers to the expanded length of each roll.

1. Rules: dry film model+dry film size+dry film length

Analysis of liquid medicine coding rules

Generally speaking, the process, form and name of liquid medicine shall be considered for the coding of liquid medicine.

1. Rules: used process+liquid medicine form+liquid medicine name

Analysis of drill bit coding rules

Generally speaking, the model, blade length and diameter of drill bit shall be considered for the coding of liquid medicine.

1. Rules: drill bit model+drill bit blade length+diameter

Analysis of coding rules for maintenance supplies

Generally speaking, maintenance supplies can be subdivided into machine maintenance, water engineering, power engineering, plant maintenance, etc., and can be coded directly by sub classification and serial number.

1. Rules: Sub classification+article name

Analysis of Consumables Coding Rules

Consumables are miscellaneous and rich in types. When coding, the general idea is to subdivide all kinds of consumables according to their purposes, and then combine the item names to carry out flow coding. Since the number and types are rather messy, this article will not give examples one by one.

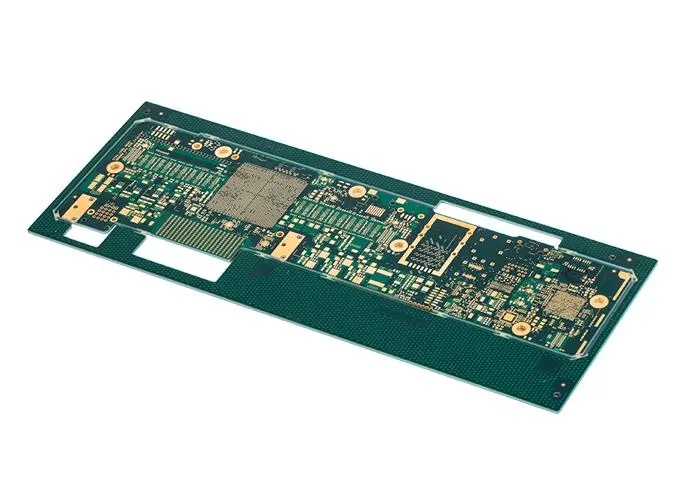

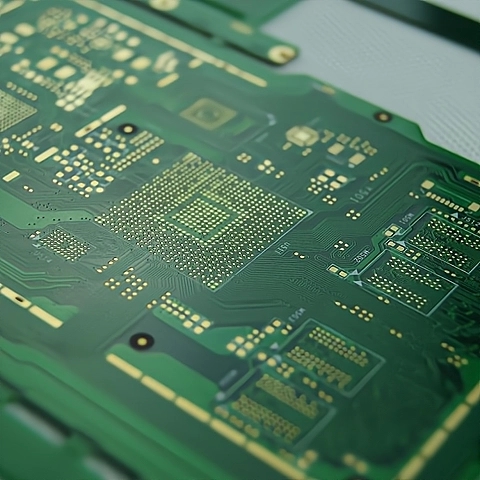

Finished product coding rule analysis

For the coding of finished products (the so-called factory coding), different enterprises have different concerns: some companies want a SIMple and clear scheme, while others want to reflect the product type, product layers, process characteristics, etc. in the coding.

The following are examples of different coding rules:

1. Scheme I: Five digit serial number+(external version+internal version)

Rule analysis: The external version and internal version of this scheme are generally controlled and processed through the ERP system, and are not actually reflected in the code. This scheme is short and fine welding, convenient for memory and quick operation. The disadvantage is that the information expressed is too little, and it is impossible to know more about the product simply by coding.

2. Scheme II: customer number+"-"+five digit serial number+(external version+internal version)

Rule analysis: The code of this scheme is relatively short, but it clearly knows which customer the product belongs to, and the code is composed of pure numbers. The operator can operate through the numeric keypad.

3. Scheme 3: Product nature+production process+layers+"-"+five digit serial code+(external version+internal version)

Rule analysis: This scheme adds more content to the code, and you can directly understand the three attributes of the product: product nature, PCB production process, and product layers. The disadvantage is that the code is too long to remember and operate.

3 Conclusion

There is no fixed rule for material coding in ERP system. As long as the overall principle of material coding is not violated, each enterprise can work with each department to formulate coding rules that conform to the actual situation of the company according to its own actual situation. It can also be improved in the process of PCB production and operation to form a material coding system suitable for the development of the company.