PCB board reading breaks through with "mICro innovation" for "big leap"

PCB manufacturers, PCB designers and PCBA manufacturers explain how to break through PCB copying by "micro innovation" instead of "big leap"

"Innovation leads to prOSPerity, and non innovation leads to death." This statement is regarded as a truth by many enterprises, who believe that innovation is the fundamental way for enterprises to survive and develop. Especially in today's era of "rampant copycat and mixed products", innovation is the only way to break the homogeneity of the industry. But with the rapid development of science and technology, it is easy to talk about innovation, but difficult to do it. The rise of the concept of "micro innovation" has brought new dawn to SMAll and medium-sized enterprises. PCB companies believe that 90% imitation and 10% innovation can also make products stand out and move forward in a down-to-earth manner in the mode of micro innovation, which will eventually lead to leapfrog development of enterprises.

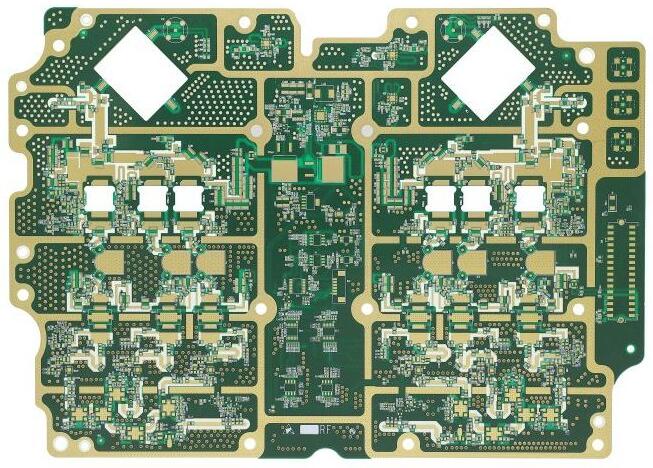

From the literal meaning, PCB copying is misunderstood by many people as a synonym of "copycat" or imitation, but in the actual operation of copying, its meaning is far more than that. PCB copying not only includes superb reverse engineering technology, but also involves PCB modification, PCB design, and software and hardware development. Through reverse technology, it can master the performance and role of the original electronic products or circuit boards for technical developers to carry out secondary innovation, that is, to delete templates and rearrange circuits according to actual needs on existing functions, so as to design better new products. Such a secondary development process is the best interpretation of "micro innovation".

There are different levels and degrees of innovation. After all, there are few groundbreaking innovations, which may require a long period of silence to have a subversive outbreak. Micro innovation may not require high investment and long-term research and development, and it is easier to break through the ground and blossom everywhere, which is also an important force to improve life and work efficiency. Investors in Silicon Valley once said that whether they like a product depends on whether it has good micro innovation. This is also a revelation in today's increasingly strong atmosphere of innovation and entrepreneurship: we should pay attention to small innovations. Innovation and entrepreneurship can not immediately step on the cloud, but need to start from small changes.

Nowadays, many core components of large domestic electronic equipment still need to be imported. Under the condition that there is still a long way to go for independent innovation, adhering to the minimally innovative way of PCB copying will gradually bring rapid progress to the R&D technology of domestic equipment.

Where to place your breakthrough heart on PCB board

At present, due to the large gap between the R&D level of high-end equipment in China's manufacturing industry and the international advanced level, and the gradual increase in the cost of imported equipment, the introduction and maintenance costs of high-end equipment in the manufacturing industry have LED to a "high cost period". How to break the development limitation of this period? Precision, innovation and standardization are the three magic weapons for enterprises to break through the cost gap. The localization of high-end spare parts through independent innovation is the center of increasing cost. After the introduction of foreign advanced technology, PCB copying can accelerate the independent innovation of domestic manufacturing equipment and help enterprises break through the "high cost period" after learning, digesting and absorbing.

Independent innovation is the basis of enterprise development

As for independent innovation, I believe it is appropriate to take the example of Apple. Steve Jobs has a classic saying: the difference between leaders and followers is whether they can innovate. According to the current development situation, I'm afraid that no company has the same innovation ability as Apple. Under the innovative guidance of Steve Jobs, the former CEO of Apple, it has brought three technological reactions and three consumer reactions. Jobs started from the concept of technology and consumption, and endowed his products with new technological value and consumption enjoyment value. Today, with the rapid development of science and technology and the serious homogenization of products, independent innovation is particularly valuable.

PCB copy reduces the starting point of independent innovation

PCB copying, also known as circuit board copying and circuit board cloning, means that on the basis of existing electronic products, reverse inference and extraction of PCB files, BOM lists and schematic diagrams are stopped, so as to complete 1:1 copying of the original electronic products or circuit boards. Then some people may have doubts. Isn't replication the behavior of followers? And independent innovation. In fact, the traditional PCB reading is mainly based on cloning. But now, after the disassembly, reverse inference and analysis of the original electronic products or equipment, the PCB reading can extract advanced technical materials, which can be used by itself after digestion and absorption. In this way, advanced technology and design concept can provide support and inSPIration for secondary development and independent innovation. By separating my own innovation elements and adding the two advantages together, we will be able to create new products of higher quality, which is the so-called "coming from behind is better than the blue". PCB manufacturers, PCB designers and PCBA manufacturers will explain how to break through the breakthrough of "micro innovation" for PCB copying.