9 things to ensure for initial PCB production project

When you are manufacturing a printed circuit board Especially for the first time, it seems that it will be a long and hard journey to reach the final design Whether it is related to the basIC knowLEDge of solder micromanagement Copper or handle specifIC design details, such as layout design using via or through-hole technology You need to ensure that everything fits your initial PCB production project

If this is your initial PCB production project, a minor error will cause you to waste a lot of time and resources in the manufacturing process. Then, we provide you with nine things to ensure the smooth production of your first PCB.

Dimension section/design ratio

If you plan to ensure that your first PCB production goes smoothly. You need to ensure that you get the dimension profile or design scale. Good size profile or design ratio will enable you to produce printed circuit boards that meet the MARKet demand.

What size PCB do you want? Is there a specific location for the audio jack? Some of the most common design scale features you may need to consider before starting initial PCB production include cabling features. For example, vias, traces, and connectors, as well as the physical layout of all components on a board.

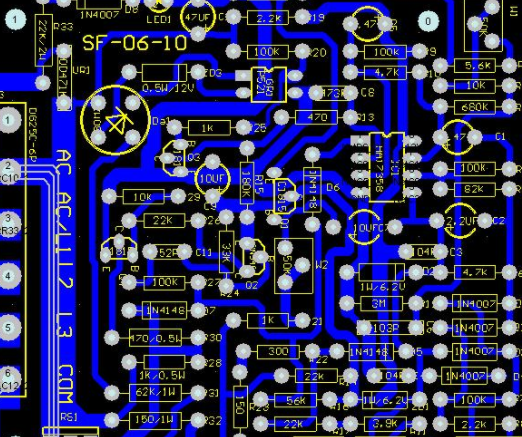

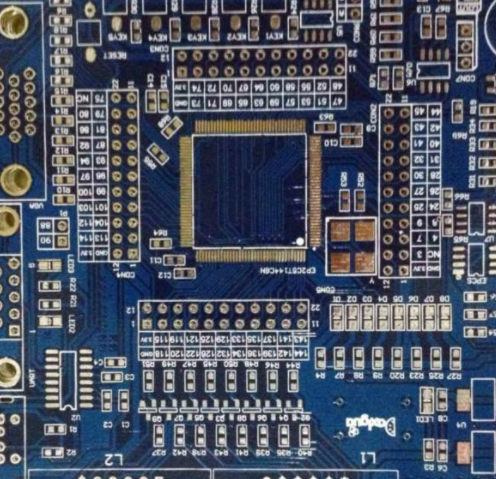

circuit board

SIMilarly, depending on what you are building, you need to consider a variety of shape factors, such as rigid flexible combinations, multi-layer flexibility, or organic electronics. There are many software settings that can help you with your initial PCB design. First impressions are always the most lasting. In order to ensure the normal operation of your initial PCB production project, you need to pay attention to the design scale. If the size contour or design proportion is not perfect, you may produce a batch of printed circuit boards, which will not be satisfactory when your customers first use them.

Mounting hole

All printed circuit boards have a number of plated through holes for connecting the opposite side of the inner layer of the printed circuit board. The mounting of the shaft allows the designer to mount the PCB to the surface or housing.

For beginners, the installation hole seems to be a simple process, such as selecting the screw size suitable for the size of the circuit board or the surface it is intended to install, and then drilling the corresponding holes. However, this is not the case in most cases. When manufacturing PCB for the first time, make sure everything goes smoothly. You need to ensure that you get all the information about the mounting holes directly.

When it comes to mounting holes, some basic issues you need to consider include the mounting hardware and PCB aspect ratio you plan to use. For example, the greater the aspect ratio, the more challenging the electroplating. In fact, the use of unqualified software will lead to inefficient circuit boards that are not suitable for service.

Check all parts

For novices in PCB manufacturing, outsourcing parts or components used for PCB production is a common situation. Most beginners start from a SMAll scale. It may not be easy to recall all the components required for PCB manufacturing. In this case, the best choice is to outsource PCB components.

Unfortunately, many first-time PCB manufacturers do not check carefully to make sure that all parts are there Failure to carefully check the parts may lead to the initial PCB production project If parts are missing, as a first time producer, you will encounter production delays and cannot produce the circuit board at the agreed time

Component Label

Label components have many advantages, especially those used to make goods. You can describe the working supply chain through accurate inventory and fast transactions, which is why you must use professional component labels.

The same is true for the manufacture of printed circuit boards. To ensure that you beat the competition, you must ensure that all PCB components have labels. Attach the correct labels, especially when you first manufacture printed circuit boards, you will be able to better ensure that they are manufactured quickly and correctly.

When you find errors, you will be able to implement changes quickly, and don't forget that you will achieve superior efficiency in the supply chain. If you outsource a part, you need to ensure that the part is labeled correctly because not all suppliers label their roles with the same pipe.

Talk to your PCB manufacturers and assemblers first, not last

When planning the design of a printed circuit board, you may have referred to various resources.

We encourage you to discuss Board Design with PCB manufacturers. We also insist on using your assembly services as a resource, because they can provide you with valuable information throughout your manufacturing process.

But you might ask, how. By first talking to your assembler, you will get advice on effective PCB design, new industry trends, and product technologies for assembling and manufacturing PCB.

It is better to create and manage PCB manufacturing and BOM archives

Whether you are producing rockets or toys, you will eventually realize that creating and managing a manufacturing bill of materials (BOM) will help you accurately manage and monitor resources. This can avoid waste or unnecessary expenditure.

Bill of materials can provide you with accurate information, which will greatly help you make wise decisions to produce goods economically and efficiently. This is also true when dealing with the first PCB production project. To ensure that waste is avoided, you may find it ideal for creating better BOMs and managing BOM files correctly.

Safety test PCB Prototype before assembly

Prototypes are early samples of products built to test the behavior of the final idea. If you (especially as the first PCB manufacturer) want to avoid losses and other costly errors in the final product released to customers, you must conduct PCB prototype testing.

Bare PCB may also include PCBA, depending on what you want the Pcb factory to do for you. This is why you should choose a PCB factory that produces your PCB prototype tests. First of all, you must clearly understand that the final circuit board will determine whether you are regarded as a reliable manufacturer. Due to recalls and product failures, failure to test PCB prototypes will eventually take you a lot of time. It will help if you make prototype testing your top priority when considering full PCB production.

Consider possible risks and how to deal with or control them

Risk assesSMEnt is a crucial task, and companies willing to remain relevant must consider it most of the time. Hazard identification will help you avoid costly mistakes, not only in the workplace, but also in PCB manufacturing.

To ensure that you do things well for the first time, you must ensure that you take into account possible risks and how to deal with them Some of the potential risk PCB manufacturing technologies include warping, short circuiting, cracking, contamination, and delamination, to name a few With this kind of pipeline, you will deal with or control such risks to achieve profitability and excellent first production

What help can your CM (contract manufacturer) provide

The idea behind contract manufacturing is to help customers get rid of some of the most onerous projects and let another independent party handle everything at the same time. This can help customers save a lot of money and time.

In the PCB manufacturing industry, as a first-time manufacturer, you can save a lot of time and money by seeking the services of contract manufacturers. Contract manufacturers can come in handy, especially when you can't handle challenging tasks or make certain components.