BasIC requirements for PCB electronic component list

In addition to maximizing the opportunity for manufacturers to deliver products, PCB punctuality, careful planning and a comprehensive bill of materials are very important for the correct operation of the circuit As a manufacturer, if you happen to forget a detail, you may eventually release a product PCB that does not meet the standard, which will damage your company's reputation Therefore, you will eventually use this PCB component on the circuit board, which is worth careful consideration At this point, we have clearly defined the basic requirements for the list of excellent electronIC components

Manufacturer's part number (MPN)

The manufacturer's part number (MPN) is a unified component code, which is identified by the entire component procurement channel (such as Mouser, Digiji, Element 14, etc.). It can identify a series of digital and alphabetic codes provided to manufacturers to identify specific PCB assemblies on the production line.

From these channels, you can easily obtain the correct MPN. Even if you choose to use basic components such as 555 timers, make sure to include the manufacturer's part number. Once the manufacturer's part number is in place, you will easily use the correct components when assembling the printed circuit board.

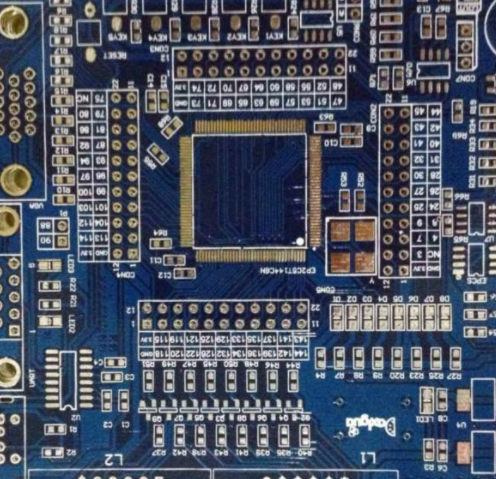

MPN at the far end of PCB assembly on this circuit board

Reference MARK

Although it is important to have the manufacturer's part number, it is also important to have a reference mark. Typically, a reference indicator can be represented by one or two letters followed by a digit. For example, you will see CR3 on the circuit board; This is a reference mark.

Circuit board

This indicator effectively specifies the PCB components used on the circuit board. Once in place, they are convenient because they ensure better placement of the same parts during assembly. Elements are not easily confused when assembling.

Description Field

Like the manufacturer's part number and reference mark, the description field is also critical to the development of printed circuit boards. This section outlines any components you need. It also describes very important information that assembly line members and end users should not use.

As a PCB manufacturer, the description field allows you to place any content you need on the PCB. In this way, you will quickly determine the exact role of each section and enter comments about any special considerations. It can also repair PCBs very smoothly because all appropriate precautions are in place.

amount

Finally, there is a quantity field when assembling the printed circuit board. The Quantity field is an important part to ensure that the number of PCB components is accurate before the assembly process starts. The quantity makes everything under inspection, especially for automatic assembly that needs to be reviewed in advance.

Consequences of Bad Parts List

If your PCB assembly list does not meet the standard, you will encounter costly errors in the manufacturing process, except for miSMAtched parts and delayed operations, which will have a negative impact on your business entity.

Sometimes, even a lack of components forces you to redo the entire work, which can lead to delivery delays. This will eventually cost you. The PCB of components manufactured and assembLED with the correct pipe is critical to the actual function of the equipment using it. A well thought out list of electronic components will help you avoid many problems that may delay PCB development or increase its cost. The following is the result of the inferior parts list.

Errors in prototype design

Prototype errors are a recent challenge for most PCB designers. For designers, we all agree that nothing is more suitable than a perfect prototype. However, in most cases, the manufacturer will tell you that your product is not ready, or has made some adjustments to the prototype.

Although there may be many reasons behind these excuses. The main errors in PCB Prototype design are mainly caused by the poorly considered PCB component list.

Act as the PCB prototype manufacturer to use unqualified parts or necessary components It is easy to understand why you will produce prototypes that cannot meet the needs of the industry Here, you may face making mistakes, which is not only costly, but also time-consuming

What's worse, if you encounter errors in your prototype design due to a hasty component list. Then, you may even lose some loyal customers' competitors. Unfortunately, many manufacturers seem to be struggling with a series of invalid PCB components, and encounter many errors in the prototype manufacturing process.

Designer of PCB prototype

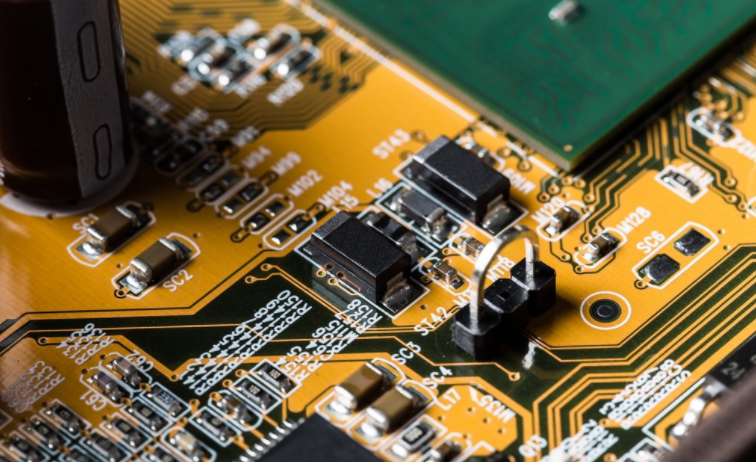

Mismatched parts

There is nothing more frustrating than bringing to market printed circuit boards containing incompatible components. In the long run, these boards may not work as expected or may crash completely.

SIMilarly, if the electronic component list you rely on does not meet the standard, you will use mismatched parts to make the circuit board. You will see an area where you will experience delays and additional costs.

An eye opening aspect of the unqualified or incomplete list is that important components may not be installed on your PCB, or these components may end up in the wrong location. In most cases, mismatched parts may need to be completely reworked, which is an expensive and time-consuming problem.

Possible results of mismatch between PCB components and parts in BOM

Higher than expected cost

Manufacturing PCBs, especially those containing multiple monolayers, is relatively expensive. In general, the goal of PCB manufacturers is to minimize manufacturing costs while achieving some profit for them.

However, this is not the case for most PCB designers. Due to the insufficient list of PCB components, the manufacturing and transportation costs of many of these products are higher than expected. Using the shallow component list, you may need to rework the entire board to fix any errors on it, which will see the correct PCB service provider. Fortunately, there are various PCB manufacturing companies that incur additional and unnecessary costs.

With a complete component list, all parts required for the manufacture of printed circuit boards will be listed. In addition, you can determine its price and purchase location as early as possible. This can avoid unnecessary costs.

flexible PCB placed on top of banknote

PCB development delay

PCB manufacturers that take a long time to manufacture customer products may lose these products, and manufacturers need shorter time to deliver such products. The customer received the PCB later than expected, which frustrated them. Unfortunately, this is true of most companies that manufacture printed circuit boards.

Due to the weakness of component list, the development delay of printed circuit board is a challenge. Due to a series of inferior components, it is difficult to manufacture printed circuit boards at the agreed time. The reason why the file is incomplete is that it takes a lot of time to make a printed circuit board, because you have to go back and forth between different suppliers to find the parts needed to complete the circuit board.

PCB delay may be caused by weak component list

Delayed operation

Printed circuit board production is a very large-scale manufacturing This is a scientific and professional work. It is necessary to make a good component list on the components that make up the circuit board Delays in PCB manufacturing are usually caused by incomplete component lists, which do not include all necessary parts that make up a printed circuit board

If the list is incomplete, you may send the customer to the manufacturer on time If the component list is incomplete, you cannot start and run production on time One aspect of delayed PCB production