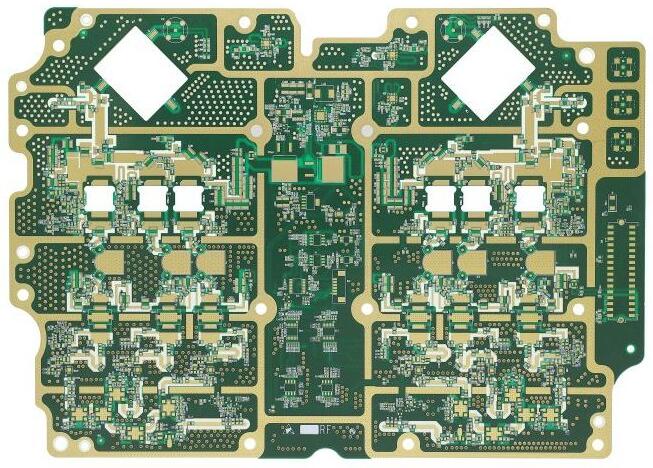

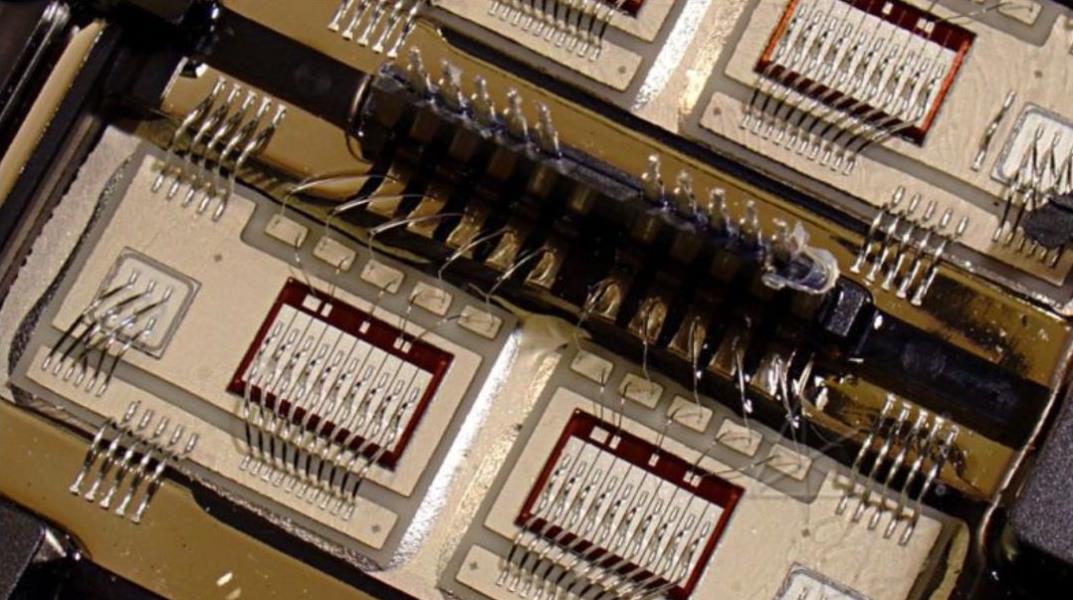

How to quICkly identify PCB green product identification

1. The understanding of restricted metals and substances is based on the analysis of their potential harm to human body.

1.1 Types of six harmful substances

1.1.1 Lead (Pb)

Highly hazardous substances enter the human body mainly in the form of dust and smoke through the reSPIratory tract and digestive tract. It is absorbed quickly through respiratory tract, about 20~30% enters into blood circulation, and about 5~10% is absorbed through digestive tract. Some studies have shown that lead is toxic, impairs the reproduction function of the human body, accumulates in the human body, causes neurological disorders, and has adverse effects on the blood system and kidneys; It also pollutes water, soil and air.

1.1.2 CADmium (Cd)

Cadmium is a by-product of zinc extraction. It is mainly used for electroplating and manufacturing alloys, solders, dyes and paint pigments, and as a stabilizer for manufacturing plastics. There is no such kind of plating in PCB industry. Studies have shown that cadmium can cause disorders of the renal system, which can lead to osteomalacia, joint pain, osteolysis and bone deformation of the human body, and affect the efficacy of beneficial elements in the human body, causing liver and kidney damage, emphysema, respiratory tract, endocrine, vascular steatosis and other diseases. It is a carcinogen and can induce prostate cancer.

1.1.3 Mercury (Hg)

Metallic mercury enters the human body in the form of vapor from the respiratory tract. The amount absorbed by the skin is SMAll, but it is more when the skin is damaged; No absorption in digestive tract; Mercury vapor easily enters the human body through the alveolar membrane and dissolves in the blood, especially in the kidney, and enters the brain through the blood brain barrier. It can inhibit the function of human protein enzyme system, cause allergy, nephrotic syndrome, immune damage, central nervous system damage, pulmonary failure, and reproductive dysfunction.

1.1.4 Chromium (Cr6+) hexavalent chromium is prohibited by the European Union because it can cause cancer or mutation. Cr6+is often used as chromic acid in the electronic industry.

Cr6+is for swallowing human poisons/inhaling human poisons, and skin contact may cause sensitivity; More likely to cause genetic defects; Inhalation can cause cancer and is a lasting hazard to human body, but metal chromium, trivalent or tetravalent chromium do not have these toxicity.

1.1.5 PBBs/PBDEs

The dioxin produced is highly toxic and stable, and belongs to a class of carcinogens. Because it is extremely difficult to separate, it cannot be discharged after human ingestion, thus posing a serious threat to human health.

1.2 Hazards of six harmful substances

Brominated flame retardants PBB and PBDE will produce highly toxic dioxins under incomplete combustion

The mechanism of dioxins harming human health is roughly in four aspects:

① It produces endocrine hormones in the human body.

② Destroy the endocrine hormone function normally secreted in human body.

③ Destroy the synthesis and metabolism of human endocrine hormones.

④ Disrupt the synthesis and metabolism of endocrine hormone receptors.

It leads to the reduction of human immune function, changes in reproductive and genetic functions, and susceptibility to malignant tumors.

Therefore, we pay more attention to these substances, our environment and our health.

2. Halogen free and lead free and understanding of restrictions and prohibitions

The restriction of ROHS directive is to prohibit the use of six harmful substances, which requires a correct understanding of the meaning of the directive.

① Prohibited:

The intentional use of a specific chEMIcal substance is prohibited. It is allowed to exist in the form of impure substances, but its use as the concentration of impure substances is limited.

2.1 Lead limit value<100ppm is lead-free

2.2 Limit value of cadmium<5ppm

2.3 Mercury limit 1000ppm

2.4 Chromium limit 1000ppm

2.5 PDD/? BDE limit 1000ppm

2.6 Halogen free chlorine (C1) (Br) content is less than 0.09% (wt) respectively.

2.7 Description of limit value

Since November 1999, Japan printed circuit Industry Association (JPGA) has successively published six standards for halogen-free copper clad laminate, which is the first operation standard for halogen-free copper clad laminate in the world. In this series of standards, the "halogen-free" characteristic of copper clad laminate has been defined for the first time: the definition standard of chlorine content or bromine content less than 0.09wt%, which was later cited by the European Union and the United States in drafting relevant or SIMilar standards; IEC has also included this definition in its standard scope. In 2000, IPC issued IPC-4101 Specification for Rigid and Multilayer Printed Board Substrates, which also includes the standard values of halogen-free IPC-4101/92, 93, 94, 95

② Restricted use:

It is allowed to intentionally use a specific chemical substance or allow it to exist in the form of impure substances with large content, and its use amount or use limit of its content has certain restricted uses.

Containment management: It is allowed to use a specific chemical substance intentionally without limiting its content, but it is required to report its content, containing parts and uses.

3. Six major substances ICP detection methods

There are many kinds of test methods for the six substances, which can be divided into soluble and insoluble test methods. The test method must be specified when sending it for testing, otherwise it will be deemed invalid,

4. How to Apply for Testing PCB Products

4.1 Raw materials and product ICP test report provided by raw material manufacturers (the contents of the report should correspond to the list of raw materials one by one, and the report is valid for one year). These ICP test reports must be issued by a recognized third party organization.

4.2 Test application process

4.2.1 Request for Application Form

Contact any of the above two tests and ask for (application form, test application process, test product quotation, and test cycle).

4.2.2 Fill in the test application form

① Report format: If SGS report needs Chinese report, it can be filLED in in Chinese; If English is required, it shall be filled in both Chinese and English. The ITS report shall be filled in both Chinese and English.

② As required, the enterprise shall give a brief description of the sample, select what test requirements, and indicate the customer (i.e. the buyer's name), manufacturer, product model, etc.

③ Determine the type of service (such as test cycle, urgency, etc.).

④ Signature and seal.

⑤ When selecting test requirements, be sure to confirm the test method, otherwise the test report will not be recognized by the customer.

4.2.3 Sample preparation

① Finished boards are available.

② Separated samples can also be provided. [For example, copper-clad laminates, polished plates with copper foil removed, and samples of film formed by ink curing (such as text, solder mask carbon film, flux, etc.)

③ The sample quantity and weight testing agencies have different requirements.

4.2.4 Test method:

① Handling by mail

Send the application form and samples to the testing company. After receiving, the testing company can make a quotation, fax it to the company in the form of "payment notice", fax it back after confirmation by the company, and provide a copy of the payment voucher to fax it to the testing company. The testing time is subject to the service type selected by the company; The original report and invoice shall be handled in the manner required by the Company,

② On site acceptance

You can also take the application form and samples directly to the testing company for cash (check) on-site payment, and confirm the "payment notice". Other procedures are the same as above.

4.2.5 Change confirmation

If there is any need to modify the test report, the applicant company can also fill in the "Application Form for Modification of Test Report", indicating the reasons and items to be modified, and pay additional fees.

5. How PCB enterprises Establish Environmental Quality Assurance System

In order to ensure that the production process of printed boards can continuously meet the environmental substance control standards and meet RBOS regulations and customer requirements. PCB company shall establish an effective environmental quality assurance system. The procedure documents can be shared with the existing ISO or QS system documents.

5.1 Managers

5.1.1 Environmental quality objectives and policies shall be established.

5.1.2 Specify that environmental quality is within the responsibility of the management representative.

5.1.3 It is stipulated that the environmental quality management system belongs to the management review.

5.1.4 Establish the organizational structure and resource responsibilities for promoting the environmental quality assurance system.

5.2 Raw material selection procedure shall be formulated for raw material selection, which shall meet the following requirements:;

5.2.1 The selected raw materials shall meet the requirements of the Company's environmental management substance control standards, and the raw material supply shall be able to meet the requirements of the Company's environmental management substance control standards.

5.2.2 A BOM (raw material list) shall be prepared to specify the names of raw materials, raw material suppliers, models, etc.

5.2.3 Relevant data of raw materials shall be obtained from the raw material supplier. ① ICP test report. ② Component List ③ Letter of Guarantee.

5.3 Product review

5.3.1 The review scope shall define and cover all main and auxiliary materials constituting PCB.

5.3.2 Review and confirmation

① According to the ICP test results, confirm whether the six environmental management substances in each material in the BOM meet the company's environmental management substance control standards one by one.

② According to the composition list provided by the raw material supplier, confirm whether there are 6 kinds of environmental management substances in the substances constituting the raw materials. If the ingredient list contains 6 kinds of environmental management substances, it must be confirmed whether the content meets the company's environmental substance control standards.

③ Data requirements

The data content, ICP report and composition list provided by raw material suppliers shall be defined, and the data must be authentic. The ICP report is certified by a third-party inspection agency (such as ITS or SGS).

5.4 Review before mass production

It shall specify the process of mass production review to confirm whether it meets the review requirements of the company's environmental management substance control standards; It shall be required that the objects participating in the review must be quality assurance, procurement, manufacturing, process technology and other departments. The review results must be approved by the company's management representative, and relevant records must be kept.

5.5 Change management

The change management procedure shall be specified, and the management control shall be carried out when the organization and supplier have any changes in the raw materials, factory and environmental quality assurance system.

5.5.1 It shall be stipulated that when any material manufacturing process and raw material supply of the raw material supplier is changed, the application for change shall be submitted and relevant evidence shall be submitted

5.5.2 It shall be specified that in case of process change involving environmental quality factors, a change application must be submitted and a test report must be provided before import.

5.6 Product management

5.6.1 It is required to specify the degree of outsourcing testing of products to prevent product pollution due to process, packaging, transportation, delivery and other possible factors.

5.6.2 In case of nonconformity, the nonconformity control shall be referred to.

5.7 Nonconformity control

A document shall be established to specify the identification, source tracking management and corrective and preventive measures for nonconforming products occurring inside and outside the company.

6. Understand China's environmental labeling system

The ecological label system is known as the "environmental labeling system" in China. In May 1994, the country established the China Environmental Labeling Product Certification Committee (CCEL), which, under the guidance of the former National Bureau of Quality and Technology Supervision and the National Environmental Protection Administration, is responsible for supervising and managing the third-party certification program. The purpose of the China Environmental Labeling Program is to serve as a supplementary tool for mandatory environmental protection activities and reduce the environmental pressure caused by production through MARKet forces. In addition, the plan seeks to enhance public awareness of the environmental impact of consumer goods and promote trade in environmentally friendly products. Since 1994, the country has implemented the environmental label certification, which is characterized by strict environmental requirements for the entire production cycle of products from design, production, use to waste disposal. At the end of 2002, China's environmental labeling has carried out the certification of 46 categories of products in household appliances and other fields. 46 corresponding technical requirements for environmental labeling products have been issued, and PCB testing has now been included in the certification plan.

7. Experience

7.1 China's accession to the WTO has won a relatively loose tariff environment for international trade. However, many developed countries and regions continue to strengthen technical barriers, which will become the most difficult barrier for China's electronic products export to break through in a long period of time. The issuance of the two directives once again gives us an example of technical barriers to trade in international trade.

7.2 Impact of technical barriers to trade,

1. Market access. Although non-tariff barriers such as quotas have been removed, technical barriers to trade have been used instead.

2. Price competition. In order to enter the market, PCB enterprises must increase investment, including equipment updating, patent introduction, talent training, etc., which is bound to increase the operating costs of enterprises and reduce the price competitiveness of products in the market.

7.3 With regard to technical barriers to trade, government agencies have formulated laws and regulations to protect and promote the coordinated development of the country's economy and environmental protection in accordance with international environmental protection standards and treaties; However, from the perspective of PCB enterprises, they should comprehensively and seriously introduce technical barriers to trade, increase their awareness of environmental protection, improve their technical level, actively carry out cleaner production, formulate effective coping strategies, and force enterprises to consider environmental protection as an important competitive factor, as well as the relationship between corporate profits, consumer demand and environmental protection. So as to effectively break the restrictions and restrictions of technical barriers to trade, so that printed board products in the market to establish an advantage in environmental protection competition.

7.4 After understanding the requirements of the directive, the company has established its own environmental system. PCB products can be branded with green marks after being tested and certified by a third party.

PCB manufacturers, PCB designers and PCBA manufacturers will explain how to quickly identify PCB green product logos.