Explanation of ceramIC circuit board solving the ultimate problem of lithium battery

circuit board manufacturing, circuit board design, PCBA processing manufacturers explain to you that ceramic circuit boards solve the ultimate problem of lithium batteries

Lithium battery is divided into lithium metal battery and lithium ion battery. Lithium metal battery belongs to a relatively new concept. Today we are going to talk about lithium ion battery, which does not contain metal lithium. Now we can use such SMAll mobile phones and portable Electronic devices, and drive electric cars for long distances. This is closely related to lithium-ion batteries. In 1992, with the advent of lithium-ion batteries, people's big brother gradually disappeared. Although it has a lot to do with the integrated circuit, if there is no lithium-ion batteries, the mobile phones today would be at least several times larger.

Lithium ion batteries are extremely sensitive to temperature. If the temperature is too low, lithium ion batteries cannot work. If the temperature is too high, just think about the tragedy of Samsung. The charging and discharging of lithium ion batteries is a chEMIcal reaction process. Under a calm surface, lithium ions run back and forth between the positive and negative electrodes. When a lithium ion battery is charged, the lithium atom of the positive electrode will lose electrons and be oxidized into lithium ions. Lithium ions enter the negative electrode through the electrolyte and obtain an electron, which will be reduced to lithium atoms. When discharging, the process is opposite. In addition, in order to prevent short circuit caused by direct contact between the positive and negative electrodes of the battery, the battery uses a diaphragm with holes to isolate the positive and negative electrodes.

Inflation, high temperature, explosion and other problems of lithium battery are usually related to overcharge, overdischarge and large current, which will cause damage to the battery. These three problems are very common, and the ultra-low temperature environment is rare. However, it is not easy for the ultra-high temperature and increasingly powerful electrical appliances. So how to obtain a stable current and how to export heat is very important. At this time, we have to talk about our ceramic PCB.

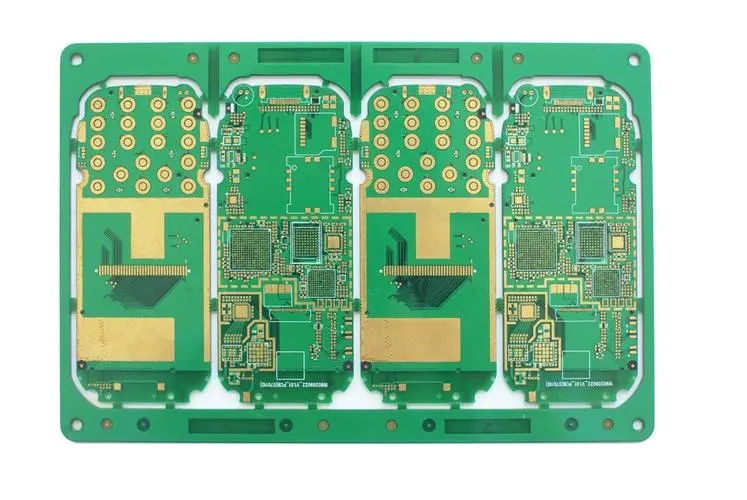

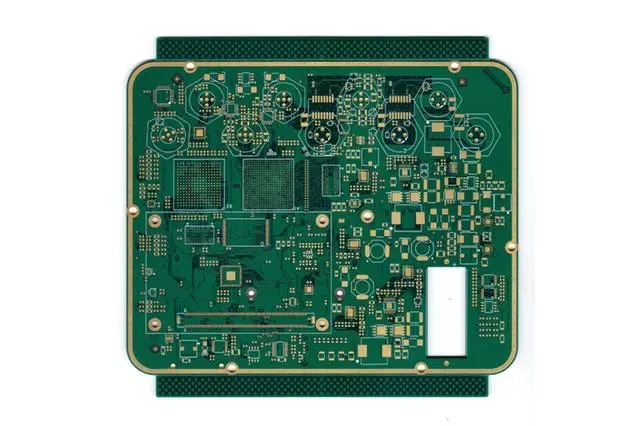

The ceramic circuit board is the PCB with the highest thermal conductivity on the MARKet at present. I believe you will understand what the high thermal conductivity of the ceramic circuit board represents, which means that all the heat emitted by the lithium ion battery can be exported in time. How can we solve the problem of high current? In addition to the circuit control system, it also has a great relationship with PCB. The higher the precision of PCB, the more uniform the circuit, which means that the current flow will be more stable.

After all, ceramic circuit boards can stand at the top of the market. The replacement of technology does not threaten ceramic circuit boards, but is an endless power. After all, ceramic circuit boards have a long way to go, and they can also be updated and iterated almost indefinitely. What we need to do is to make good use of it.

Huawei took the lead in introducing graphene lithium-ion battery. The role of graphene in it is pure heat conduction, but graphene has not yet been commercialized. There is still a long way to go in the commercialization of graphene. Users are most concerned about when to achieve commercialization. Commercialized technology can benefit users and promote the development of lithium battery industry. As a very mature product, ceramic circuit board is still the king at present.

Whether it is ceramic circuit board or graphene in the future, it is not our scope of consideration. We only need to know which can meet the demand better. The life and death of products are determined by the market. Ceramic circuit board is not only a market direction of lithium ion batteries, but also includes LED, aerOSPace, etc., which are among the most promising industries at present or in the next century. It can be predicted that, Ceramic circuit boards will certainly leave a strong mark on the stage of electronic industry history.

circuit board manufacturers, circuit board designers and PCBA manufacturers explain to you that ceramic circuit boards solve the ultimate problem of lithium batteries.