In the rapid development of PCB products, high-density multi-function miniaturization has become the development direction. The components on the printed circuit board are increasing with geometrIC index, while the size of the printed circuit board is decreasing, so it is often necessary to match some SMAll carrier boards. If the round hole of the small carrier plate is welded to the parent circuit board with solder, due to the large volume of the round hole and the problem of faulty soldering, the sub parent printed circuit board cannot be connected electrically well, so a metallized half hole PCB appears The characteristics of the metallized half hole PCB are: the individual is relatively small, and there is a whole row of metallized half holes on the side of the unit. As a sub board of a motherboard, these half holes are welded together with the motherboard and the pins of components.

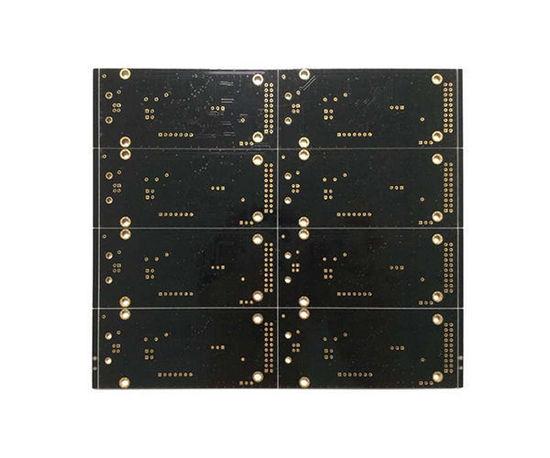

Half orifice plate

Difficulties in metalized PCB processing:

The copper skin on the hole wall of the metallized sEMI orifice PCB after forming is black, burr remains, and deviation is always a difficult problem in the forming process of PCB manufacturers. In particular, the whole row of half holes, which are SIMilar to stamp holes, have an aperture of about 0.6 mm, a hole wall spacing of 0.45 mm, and an outer layer pattern spacing of 2 mm. Because the spacing is very small, it is very easy to cause a short circuit due to the copper sheet.

The general processing methods for forming metallized semi orifice PCB include numerical control milling machine gongs, mechanical punch punching, VCUT cutting, etc. When removing the copper that does not need some holes, these processing methods will inevitably lead to copper wires and burrs left on the section of the remaining PTH holes, and even the copper skin of the hole wall will be warped and peeLED off seriously. On the other hand, during the forming of metallized half holes, due to the influence of PCB expansion and contraction, drilling hole location accuracy and forming accuracy, the size deviation of the remaining half holes on the left and right sides of the same unit is large, which brings great trouble to PCB welding assembly.

Traditional metallized half orifice plate:

Drilling - chemical copper - full plate copper - image transfer - pattern electroplating - film stripping - etching - resistance welding - surface coating half hole (formed at the same time with the shape).

This kind of metallized half hole is formed by cutting the round hole in half after forming the round hole. It is easy to have the phenomenon of half hole copper wire residue and copper skin warping, which affects the half hole function, thus leading to the decline of product performance and yield. To overcome the above defects, the following technological process steps of metallized semi orifice PCB shall be followed:

After secondary copper plating and tin plating on the substrate, the round hole on the edge of the plate is cut in half to form a half hole. Since the copper layer on the hole wall is covered with a tin layer, and the copper layer on the hole wall is completely connected with the copper layer on the outer layer of the substrate, the drag binding force is large, which can effectively avoid the phenomenon that the copper layer on the hole wall is pulled off or the copper is cocked up when cutting;

After the forming of the half hole board is completed, the film is removed and then etched to avoid copper surface oxidation, effectively avoiding copper residue and even short circuit, and improving the yield of the metallized half hole board PCB.