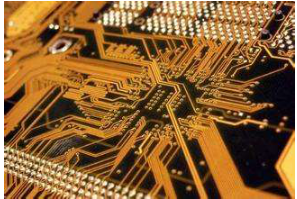

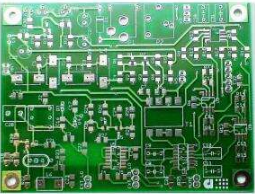

The method for preventing the nICkel gold layer of the selective PCBfrom being corroded mainly includes step A: manufacturing the selective PCB; B: Immerse the concentrator board in the aqueous phase sealing agent solution with the concentration of 5% - 15% and pH value of 8.5~9.5 for 1~2 minutes to form a protective film on the nickel gold layer of the concentrator PCB board; C: OSP processing is performed for the selection. Before the OSP treatment of the selective plate, the selective plate is immersed in the aqueous phase pore sealing agent solution to form a protective film on the nickel gold layer of the selective PCB. When the OSP treatment is required, the micro etching agent cannot enter the atomic pores in the nickel gold layer, thus avoiding the corrosion and blackening of the nickel gold layer by the micro etching agent. The final surface treatment of PCB board mainly includes OSP organic flux, chEMIcal tin, chemical silver, chemical nickel gold, lead-free tin spraying and rosin coating. Rosin coating will be gradually eliminated by the first five with the further improvement of environmental requirements.

Compared with the five mainstream surface treatment methods, OSP has gained a large share of PCB market with its low cost advantage

OSP organic flux, also known as water-soluble organic flux, is more popular in China as copper surface antioxidant, which is a lead-free, water-soluble and environmentally friendly product. By selectively depositing a layer of organic solder mask on the fresh copper surface of the PCB, it can avoid the poor tin coating caused by the oxidation of the copper surface of the PCB before SMT/SMD. The organic film will be dissolved by the flux during the SMT/SMD process, and the fresh copper surface will be exposed, so the metal tin can be easily expanded and combined on the copper surface. The OSP treated PCB board has a flat surface, which is very conducive to tin spreading.

Because of the good prospect of OSP, most PCB liquid medicine manufacturers will have commercialized OSP liquid medicine. The well-known brands in the industry are Shikoku's F2 series, Sanwa's CuCcoat GV, Tamura's WPF-21, and Enthone OMI's Cu-106A series. There are also some PCB liquid medicine suppliers in China that can provide commercialized OSP liquid medicine The main processes of OSP are: degreasing/degreasing, abrasive brushing, micro etching and OSP film deposition.

The pre process of OSP has a very important influence on the deposition of OSP film. Poor pretreatment will lead to poor deposition effect of OSP film or even failure of OSP film deposition.