Introduce foreign advanced "5S" management concept. Here, I would like to share with you the working environment management specifICations for SMT mounters.

1、 SMT chip material management

The material placement standard shall be formulated, and all materials shall be placed in a fixed area, a fixed frame and a fixed position according to the requirements, and shall be labeLED accordingly. The retrieval and playback of materials are guided by corresponding operation specifications and recorded accordingly.

2、 Environmental management of machine shop

The production workshop of SMT mounter shall formulate a production management system, requiring workshop personnel to observe the process discipline and operate in strict accordance with the operating procedures; All equipment, articles, raw materials and tools shall be free of dust; Stairs and floors shall be smooth and clean without garbage; Doors and windows are clean and dust-free; The public passage is unblocked and free of sundries; "One day inspection" and "daily inspection and daily clearing" shall be achieved, and corresponding inspection and records shall be made every day.

The cleanliness, temperature and humidity of SMT mounter workshop shall be controlled according to PCB process documents. Workshop air cleanliness is 100000 (BGJ73-84); In an air-conditioned environment, there should be a certain amount of fresh air. Try to control the CO2 content below 1000PPM and the CO content below 10PPM to ensure human health. The best ambient temperature in the workshop is 23 ± 3 ℃, and the limit temperature is 15~35 ℃; The relative humidity is 45%~70% RH. Curtain the windows on the wall to avoid direct sunlight on the equipment. All operations are recorded. Lighting shall be arranged in the plant with illumination of 800~1200lx. At least 300lx. In case of low illumination, local lighting shall be set.

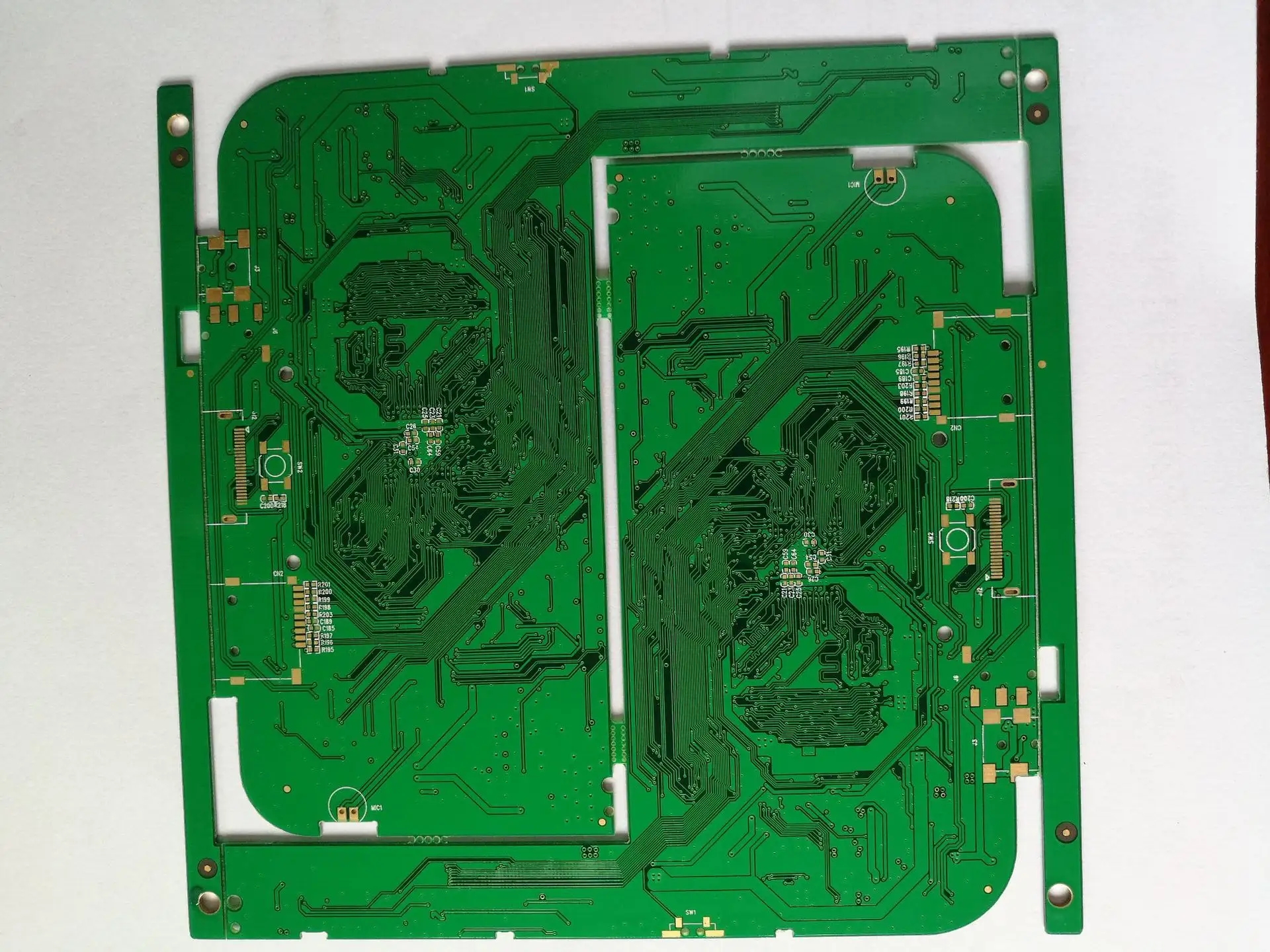

SMT patch

3、 Control of SMT mounter supporting facilities

1. Power control of SMT mounter

The power supply voltage shall be stable, generally single-phase AC 220V, three-phase AC 380V. The power supply of the mounting machine is required to be grounded independently. Generally, the three-phase five wire wiring method is adopted. The working zero line and the protection line of the power supply are connected strictly separately. Line filter or AC voltage stabilizer shall be installed in front of the transformer of the equipment.

2. Control of air supply of SMT mounter

Configure the pressure of air source according to the requirements of equipment. Generally, the pressure is required to be greater than 7KG/cm2. The compressed air shall be introduced into the corresponding equipment of the production line through the uniformly equipped air supply network, and the air compressor shall be at a certain distance from the SMT production workshop; The compressed air shall be subject to oil removal, dust removal and water removal.

3. Control of exhaust air volume of SMT mounter production line

Both reflow welding and wave soldering equipment have exhaust requirements, and exhaust fans are configured according to equipment requirements. The minimum flow value of the exhaust duct of the full hot air furnace is generally controlled at 500 cubic feet per minute.